Central hole punching device

A technology for drilling center holes and central shafts, which is applied to boring/drilling devices, drilling/drilling equipment, parts of boring machines/drilling machines, etc. It can solve the problems of simultaneous processing efficiency and low processing accuracy, and achieve convenient operation, Effect of cost reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

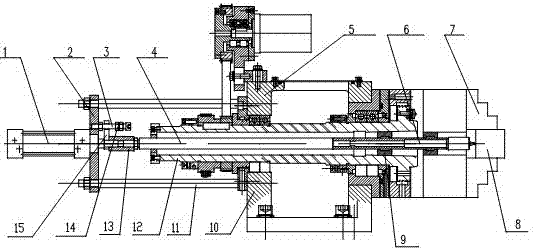

[0012] As shown in the figure, this embodiment includes a spindle assembly 5 , and the front end of the spindle assembly fixes a workpiece 8 through a chuck 7 . The main shaft assembly 5 has its main shaft seat 10 and the central shaft 12 installed on the main shaft seat 10 by bearings. In this embodiment, the central shaft 12 is a tubular structure, and its inner cavity is equipped with a push rod 4 through the support member 9. The support member 9 is fixedly connected with the inner cavity of the central shaft 12, and the push rod 4 and the support member 9 are dynamically matched. , The front end of the push rod 4 is provided with a mounting mechanism for the center drill 12 . At the rear end of the main shaft seat 10, a coupling plate 2 is installed through a set of pull rods 11, and the push cylinder 1 is fixed on the rear side of the coupling plate 2. The rear end of the push cylinder 1 is connected, and the piston rod and the ejector rod 4 of the cylinder 1 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com