Pneumatic tire

A technology for pneumatic tires and treads, which is applied to the reinforcement layer of pneumatic tires, tire parts, tires, etc., and can solve problems such as pull-out and difficulty of sipe blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

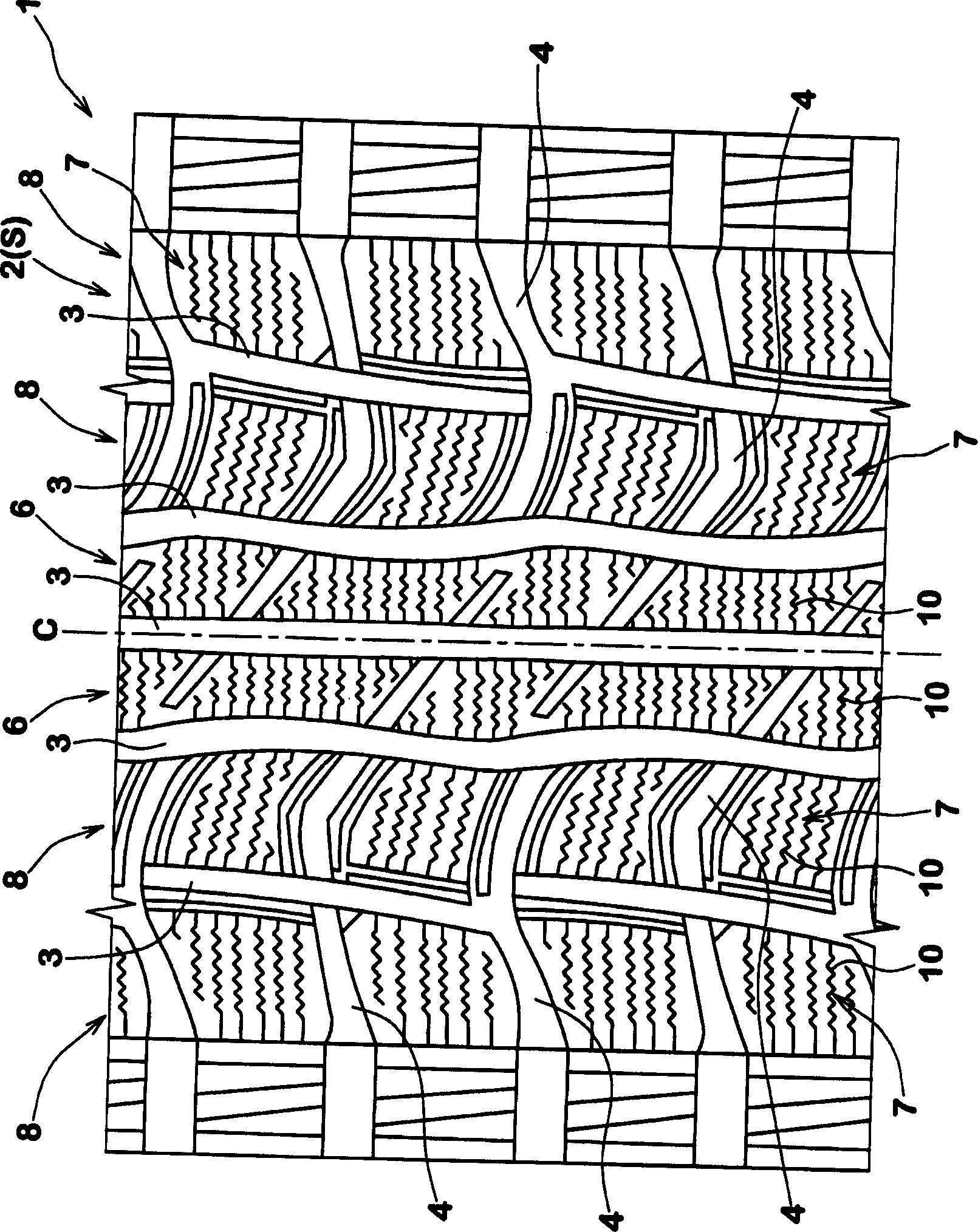

[0023] figure 1 One example of the tread pattern used for this studless tire is shown.

[0024] The tread portion 2 has tread grooves 3 and 4 to divide the tread portion 2 into tread elements 6 and 7 .

[0025] The tread grooves 3 and 4 are used for water drainage, and their width is preferably 3.5 mm or more.

[0026] figure 1 Among them, the tread groove includes a circumferential main groove 3 extending in the tire circumferential direction and a transverse main groove 4 extending in a direction intersecting with the circumferential main groove 3, thereby forming stripes on each side of the tire equator C 6, and two circumferential rows 8 of blocks 7 are formed on the axially outer side of the strip 6. Therefore, in this embodiment, the tread pattern is a so-called rib-block pattern. However, other tread patterns may also be provided, for example a block pattern consisting only of blocks.

[0027] According to the invention, the tread elements, ie strips 6, blocks 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com