Safety belt outlet structure

A technology of export structure and safety belt, which is applied in the field of auto parts, can solve problems such as labor-intensive, affect appearance, and improper assembly, and achieve the effects of smooth pulling, avoiding appearance problems, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

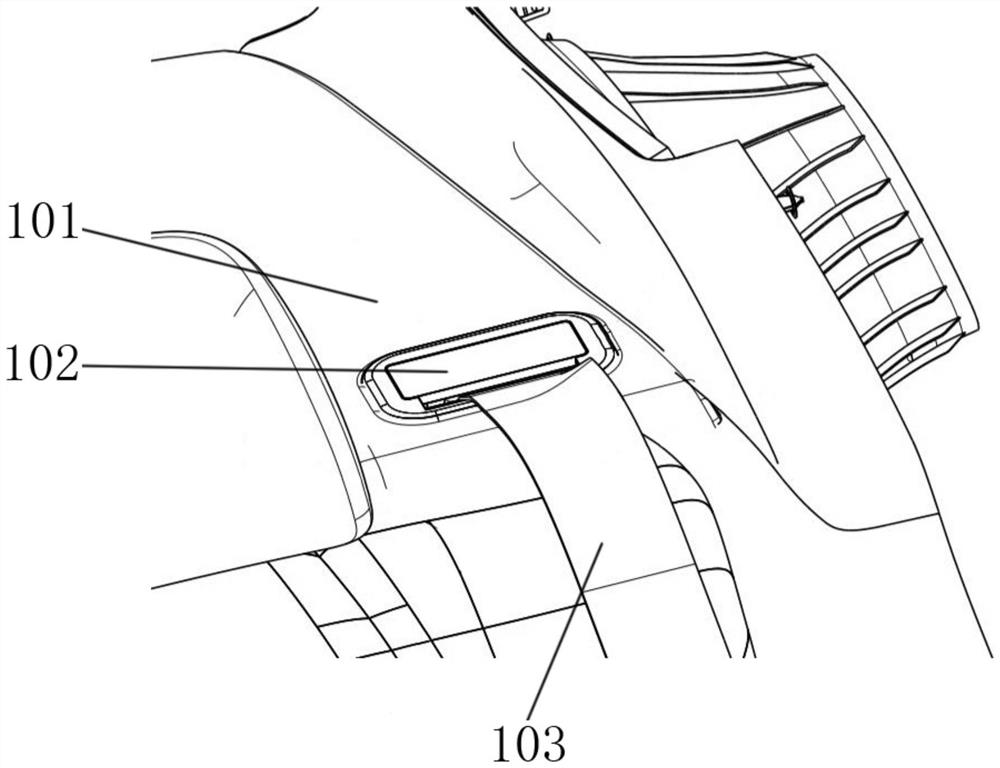

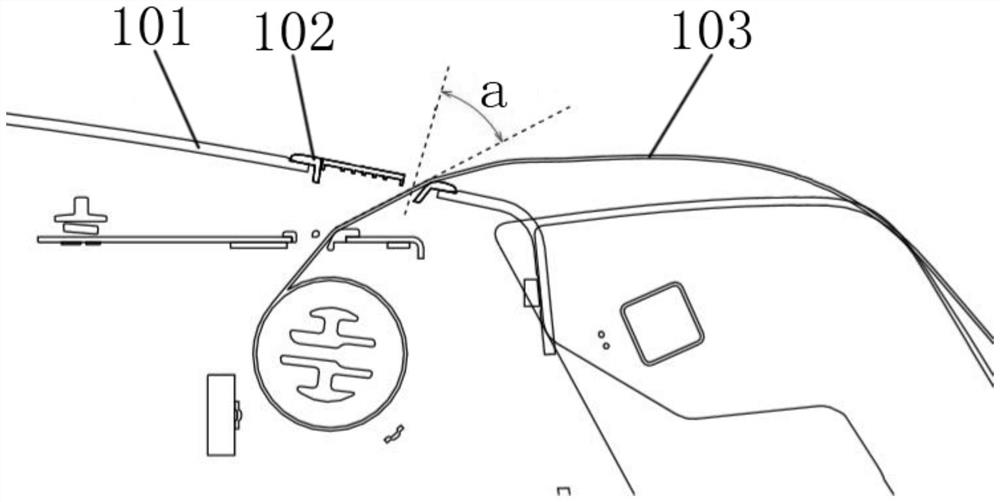

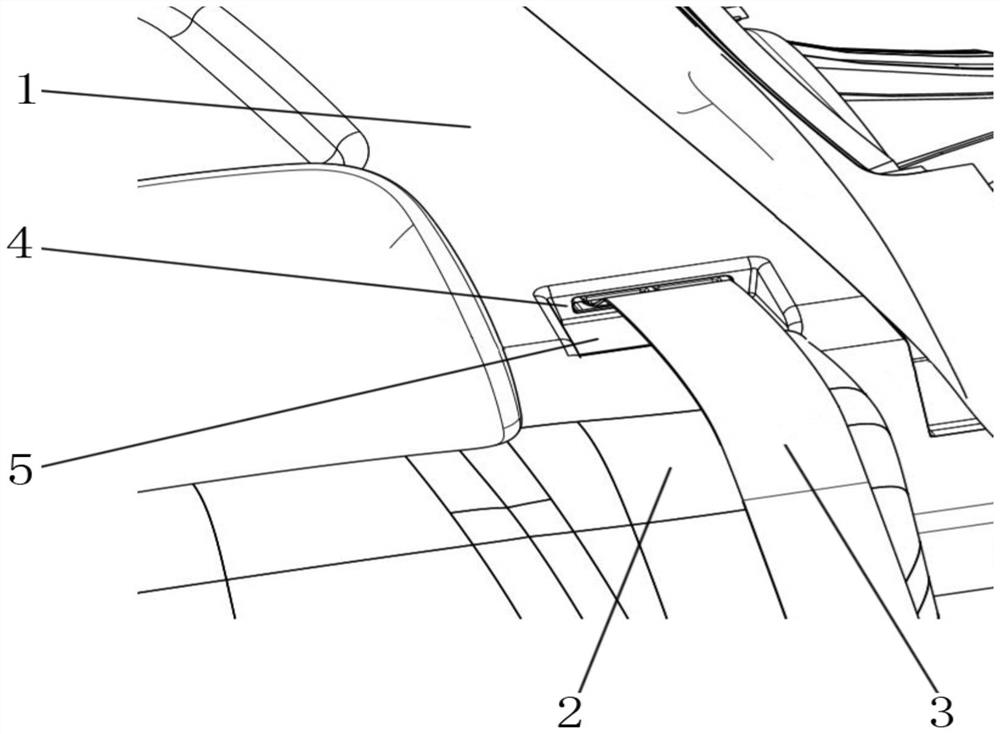

[0022] Such as Figure 3 to Figure 5 The shown safety belt exit structure includes a shelf, on which a sunken platform 4 formed by a part of the shelf is recessed downward, and the sunken platform 4 is composed of a rear side wall 41, a lower side wall 42, Surrounded by the left side wall 45 and the right side wall 46, that is to say, the sunken platform 4 is a structure with front and upper openings, the rear side wall 41 is set facing forward, the lower side wall 42 is set facing upward, and the upper side wall 41 A safety belt exit 43 is provided. By adopting the above-mentioned technical scheme, the countertop 4 is integrally formed with the shelf, and the safety belt outlet 43 is directly arranged on the shelf, thereby reducing the decoration parts of the safety belt outlet. By arranging the sunken platform 4, and setting the safety belt outlet 43 on the rear side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com