Output buffer circuit for drive voltage in liquid crystal display drive control chip

An output buffer and drive control technology, applied in static indicators, instruments, etc., can solve the problems of complex output buffer circuit structure, poor stability, large static bias current, etc., to save area, good stability, reduce static The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

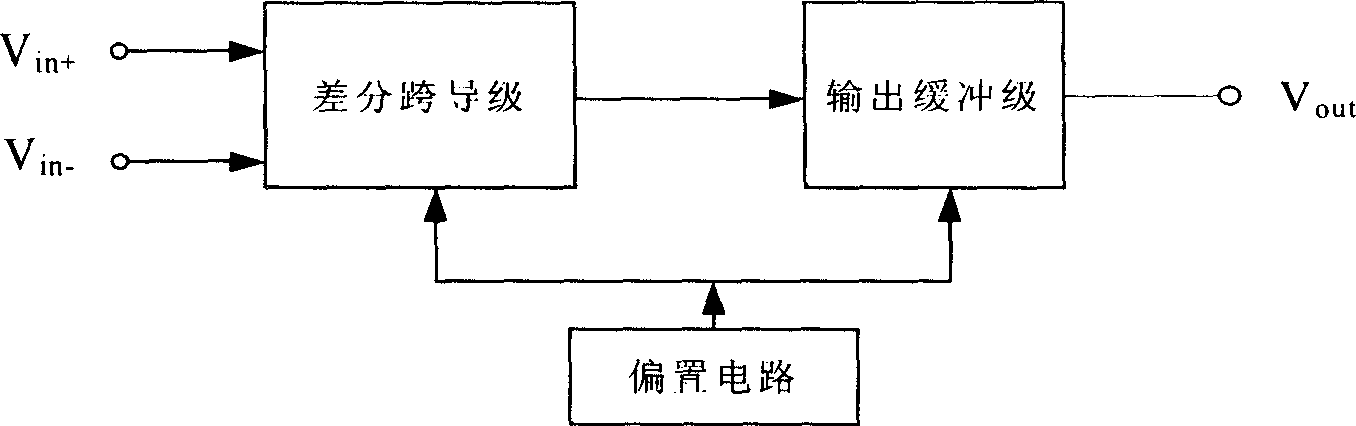

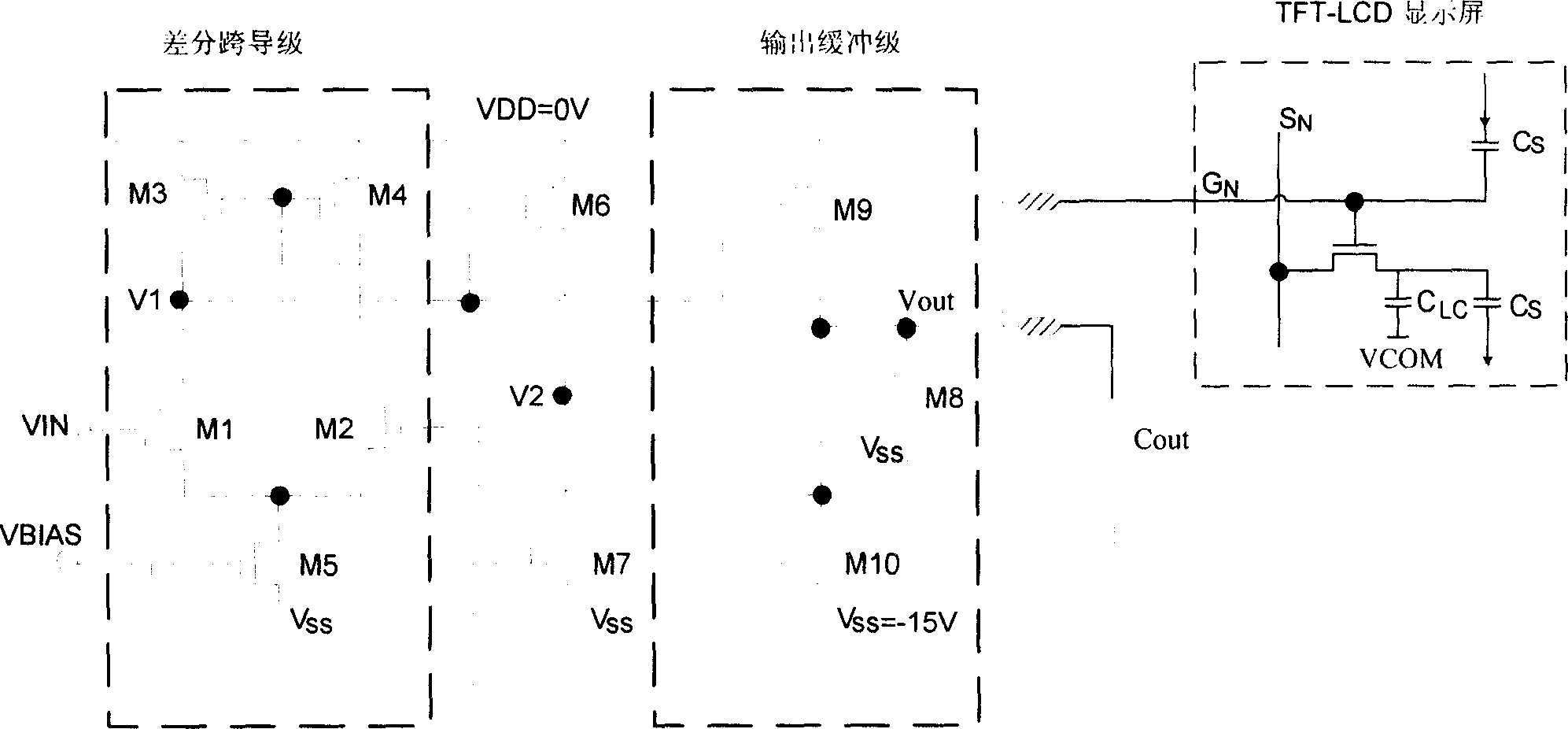

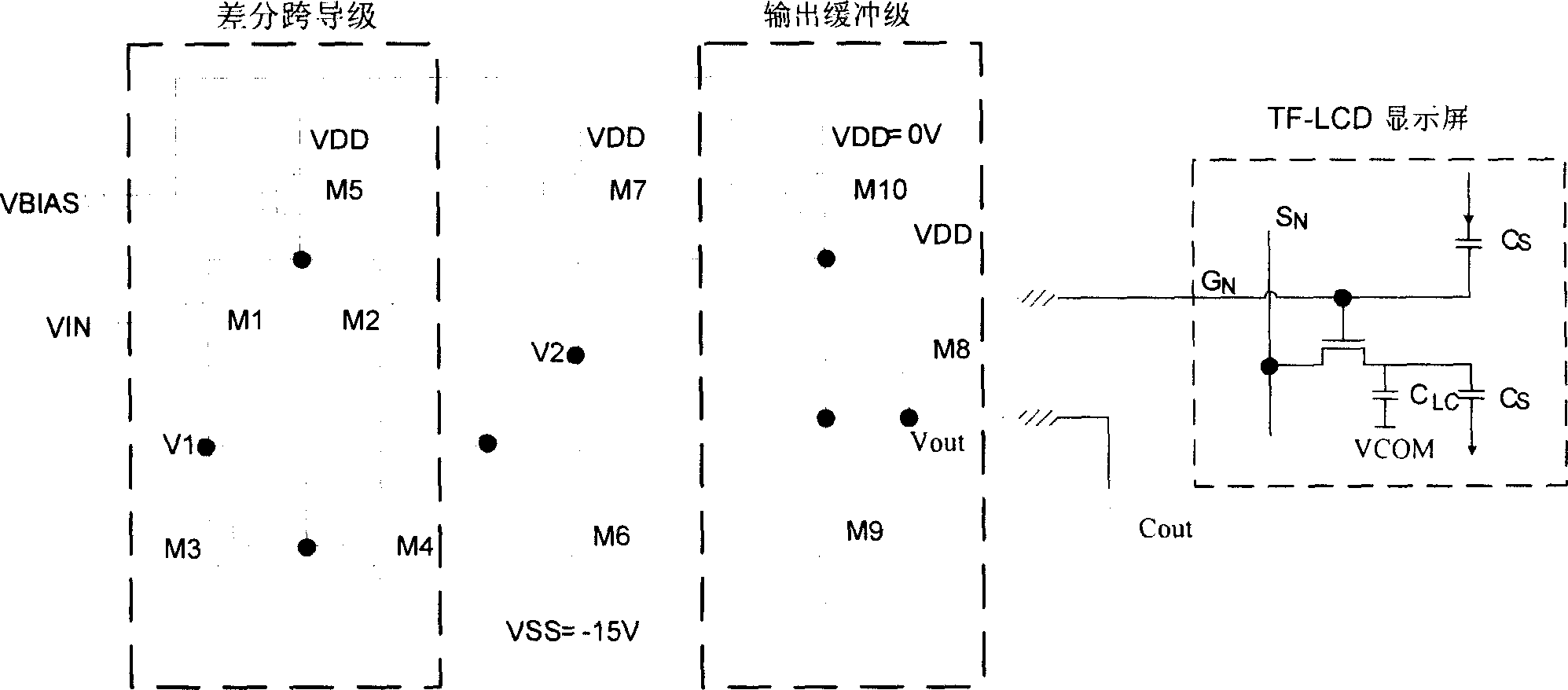

[0017] refer to Figure 1~3 The output buffer circuit of the driving voltage provided by the present invention includes a differential transconductance stage, an output buffer stage two-stage amplifier, and an external bias circuit.

[0018] The output voltage V1 of the differential transconductance stage is directly added to the input terminal of the common source amplifier circuit, and the output terminal of the common source amplifier circuit is connected with the output terminal of the source follower as the output terminal of the output buffer circuit. The output voltage V1 of the differential transconductance stage is added to the floating bias circuit of the source follower at the same time, and the floating bias voltage V2 generated is added to the input terminal of the source follower. The bias circuit provides a fixed DC bias voltage VBIAS to the differential transconductance stage and the output buffer stage.

[0019] The structures and working principles of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com