Method for preparing substituted diesel oil by utilizing organic waste and coal

A technology of organic waste and coal, applied in the energy field, can solve the problems of complex equipment and process, difficult to popularize and apply, and high cost, and achieve the effect of short construction period, alleviation of fuel shortage, and fast production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

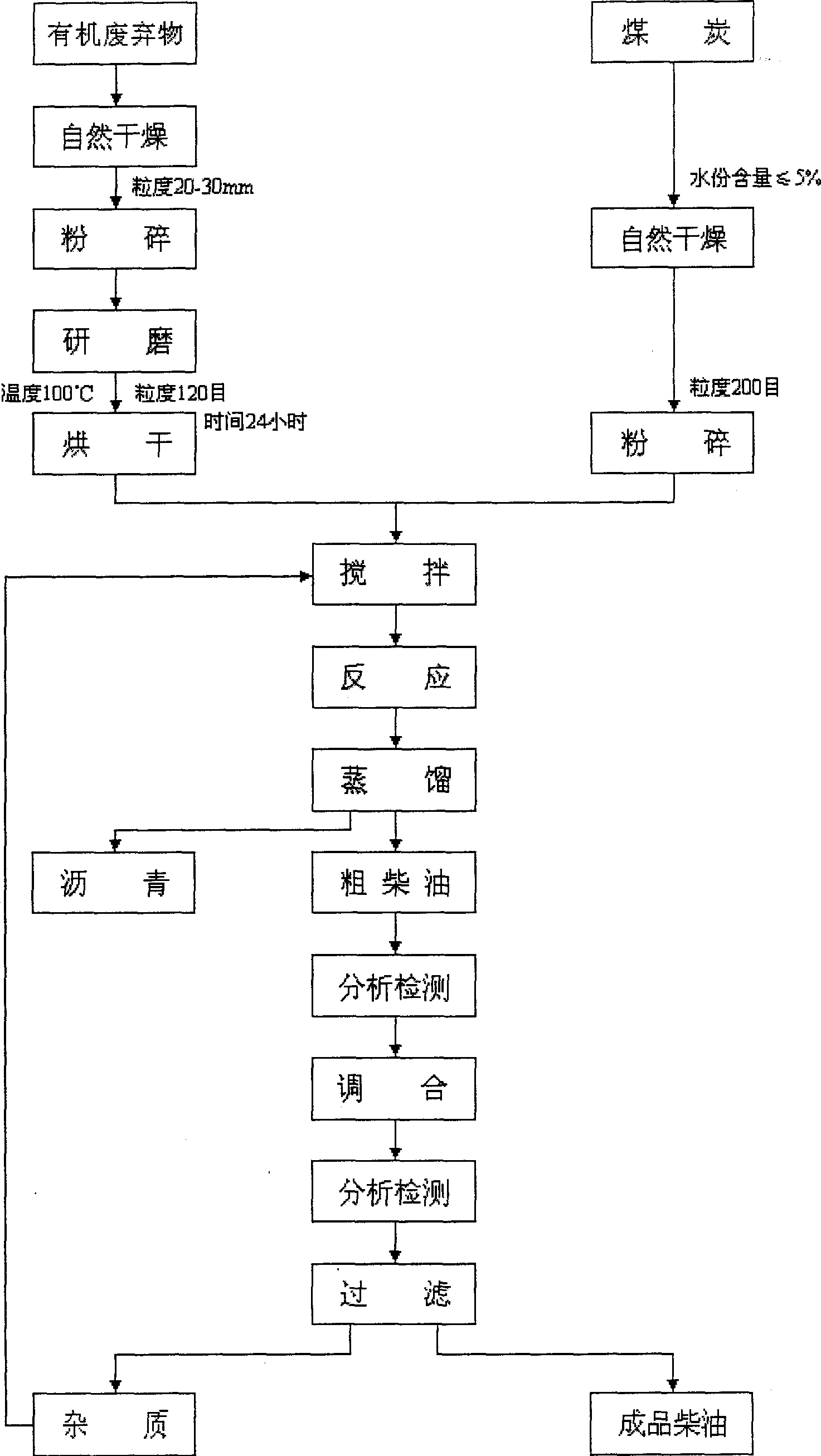

Image

Examples

Embodiment 1

[0022] Production substitute diesel oil, at first prepare enough needed various materials, then, by the composition formula provided by the present invention and its content (weight %) ratio, i.e. coal 15.0, organic waste 45.0, solvent 30.0, auxiliary agent 9.0, catalyst 1.0 ; Weighing the required materials, using 150kg of Shenyang Puhe Mine coal, 450kg of corncobs or peanut shells as organic waste, 300kg of refined anthracene oil as the solvent, 90kg of methanol as the auxiliary agent, and 10kg of catalyst aluminum chloride ; Organic waste corncobs or peanut shells must first be pretreated. After the organic waste is naturally dried, the water content should be ≤ 5%, and then transferred to the crushing and grinding process. The grinding particle size should be 120 mesh. After that, it should be transferred to Drying in the drying room, the drying temperature is 100°C, and the drying time is 24 hours; the coal should also be dried naturally, and the water content should be ≤ ...

Embodiment 2

[0025] Prepare the required raw materials to make diesel oil instead. Component ratio (weight %) provided according to the present invention: coal 20, organic waste 40, solvent 30, auxiliary agent 9, catalyst 1, weighing 200kg of iron mine coal, organic waste adopts rice husk or cotton orange 400kg , 90kg of methanol is used as the auxiliary agent, 10kg of aluminum chloride is used as the catalyst, and the distillate oil at 340-380°C in the distillation process is used as the solvent for recycling; after the raw coal and organic waste are pretreated, they are transferred to the agitator together with the auxiliary agent and catalyst, and stirred After 10 minutes, fully stir and transfer to the reaction process, the reaction kettle is heated to 300°C, the reaction pressure is 5.0MPa, and the reaction time is 1.5 hours. Other each operation and technological condition are all identical with embodiment 1. The process method can also produce qualified substitute diesel oil.

Embodiment 3

[0027] According to the component formula and the content (weight %) ratio provided by the invention, all raw materials are prepared to produce substitute diesel oil.

[0028] According to the component formula (weight %) ratio, coal 25, organic waste 35, solvent 30, auxiliary agent 9, catalyst 1, weigh each material, get Beipiao coal 250kg, organic waste bean orange or wheat orange 350kg, solvent 300kg, the distillate oil at the temperature of 340-380℃ in the distillation process is used for recycling, the additive cetyl alcohol is 90kg, and the catalyst aluminum chloride is 10kg; after all materials are prepared and pretreated, coal, organic waste, additives 1. The catalyst is put into the stirrer and fully stirred. The stirring time is 15 minutes, and then transferred to the reaction process. The reaction temperature is 350 ° C, the reaction pressure is 5.5 MPa, and the reaction time is 2 hours; Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com