Silicon carbide-cordierite composite porous ceramic and its preparation method

A kind of technology of porous ceramics, cordierite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

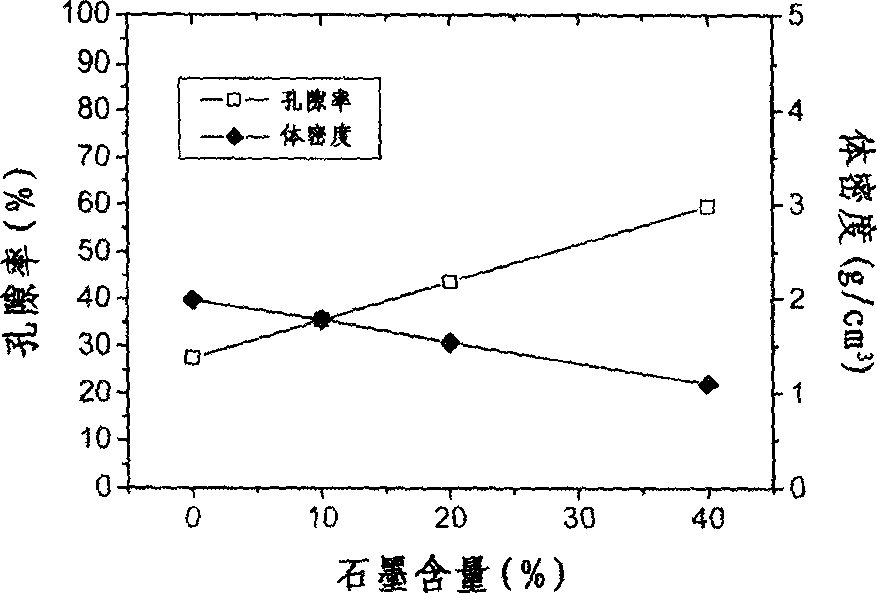

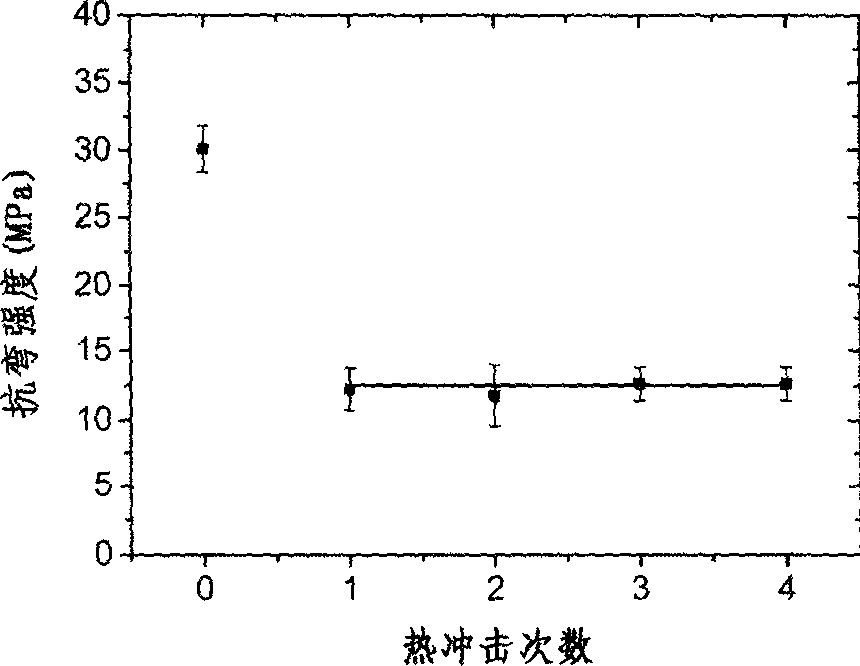

[0021] The starting materials for synthesizing cordierite are clay, talc and alumina powder, the median particle sizes are 0.6, 7.0 and 0.8 μm respectively, and the total content of impurities (calculated as oxides) is all lower than 1.0 wt%. The silicon carbide used is commercial silicon carbide powder of α phase, with a median particle size of 21.1 μm and a purity of 98.8 wt%. Graphite powder is selected as the pore-forming agent, the median particle size of the graphite powder is 10.0 μm, and the purity is 99.9 wt%. First, mix 420g of clay, 430g of talc and 150g of alumina powder with a ball mill for 4h. 1000g of ethanol was used as the dispersion medium, and the amount of alumina grinding balls was 2000g. Then, 1500 g of silicon carbide powder, 1500 g of ethanol, and 3000 g of balls were added to the above mixed material, and ball milling was continued for 8 hours. Afterwards, add 625g of graphite powder in this mixed material again, and ball mill 1h. The slurry was tak...

Embodiment 2

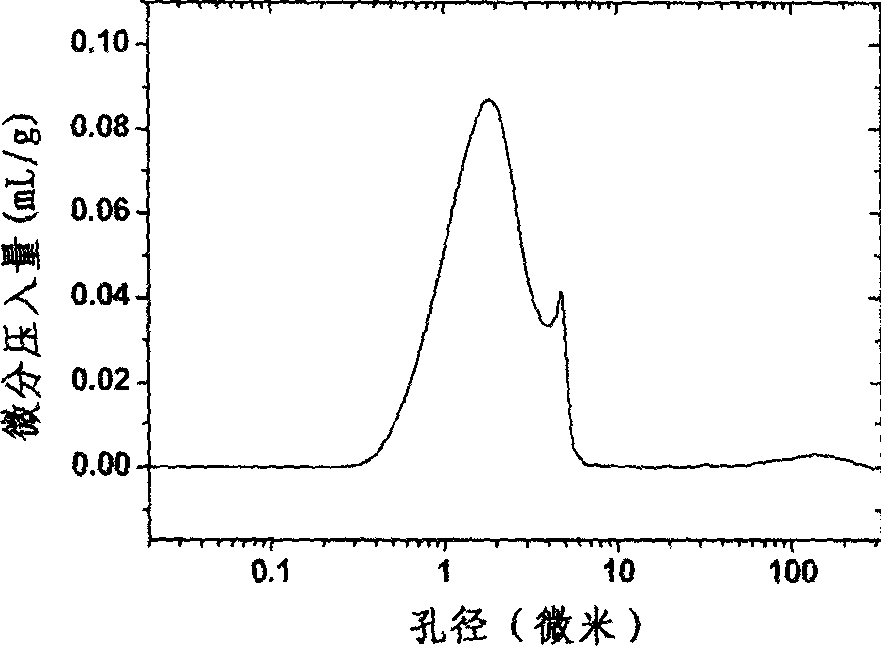

[0025] Raw material and technological process are with embodiment 1. The formula of raw materials is: clay 420g, talc 430g, alumina powder 150g, silicon carbide powder 1500g, graphite powder 0g. The obtained porous ceramic sample has a porosity of 27.6%, a flexural strength of 54.6±3.4MPa, and a thermal expansion coefficient of 3.99×10 -6 K -1 (20~800℃). The pore size distribution is similar to figure 2 The bimodal pattern shown.

Embodiment 3

[0027]Raw material and technological process are with embodiment 1. The formula of raw materials is: clay 630g, talc 645g, alumina powder 225g, silicon carbide powder 1000g, graphite powder 0g. The obtained porous ceramic sample has a porosity of 24.5%, a flexural strength of 40.1±2.2MPa, and a thermal expansion coefficient of 2.60×10 -6 K -1 (20~800℃). The pore size distribution is similar to figure 2 The bimodal pattern shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com