Wire-drawing equipment for polymer photon crystal optical fiber preformed rod

A photonic crystal optical fiber and preform technology, which is applied in the field of optical fiber manufacturing equipment, can solve the problems of large equipment volume, high heating temperature and high cost, and achieve the effects of small size, uniform traction and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

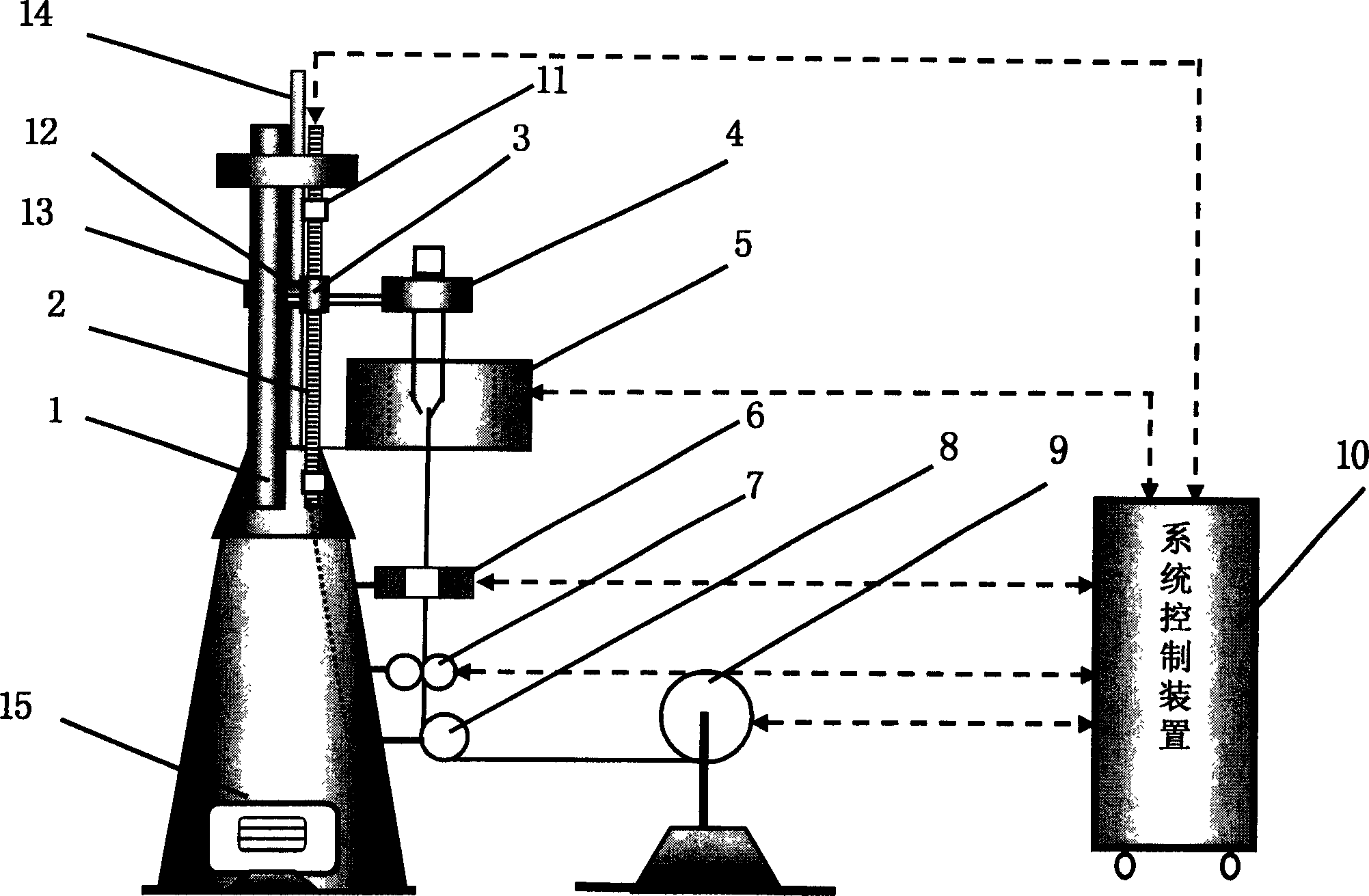

[0031] The invention is a device for making a porous microstructure optical fiber with a transparent polymer material. That is, after the polymer photonic crystal fiber preform is made, it can be drawn into polymer photonic crystal fibers of different specifications by using the present invention.

[0032] see figure 1 , the temperature sensor of the heating furnace 5 of the present invention, the diameter measuring device 6, the wire drawing device 7, the guide wheel 8, the wire receiving device 9, the preform rod clamp and the drive motor 15 of the preform rod clamp are respectively connected to the system control device 10 through wires. The preform clamp is fixed on the column 1, the heating furnace 5 is located below the preform clamp, the preform is placed in the heating furnace 5, the wire drawing device 7 is located below the heating furnace 5, and the guide wheel 8 is arranged below the wire drawing device 7. The clamping head 4 of the preform clamp is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com