Biological oxidant for fermented cryogenic flour dough

A technology of freezing dough and oxidizing agents, which is applied in the field of food processing, and can solve the problems of destroying the gluten network structure, weakening the gluten structure, and reducing the specific volume of bread, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

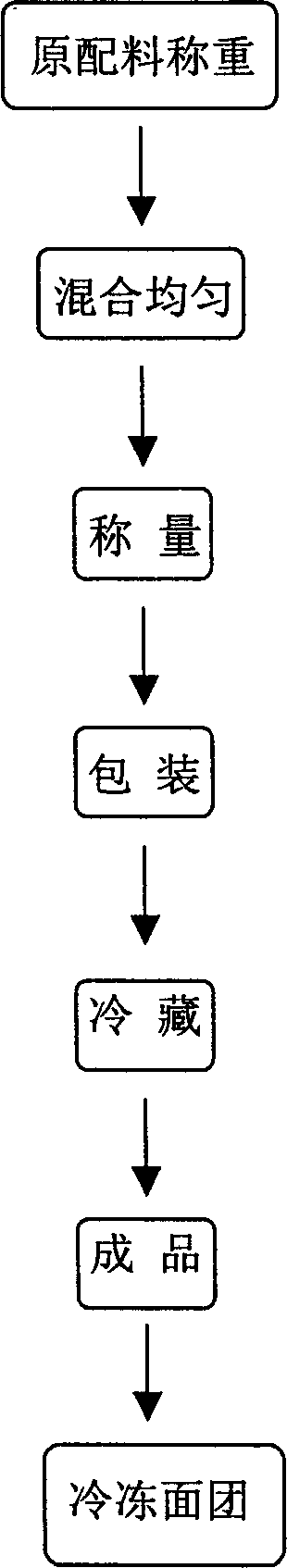

Image

Examples

Embodiment 1

[0011] In the embodiment of the present invention, transglutaminase: 80.0% by weight, ascorbic acid: 0.5% by weight, trehalose: 2.5% by weight, guar gum: 17.0% by weight; transglutaminase, ascorbic acid, seaweed Sugar and guar gum are mixed evenly in a mixing tank in proportion at room temperature, and the rotation speed of the mixer is: 100-120 rpm; then weighed and packaged according to the packaging standard, and refrigerated storage is the finished product of biological oxidant. Refrigeration temperature: 0 ~ 4 ℃.

[0012] In this embodiment, the biological oxidant is: 0.008% by weight, wheat flour: 51% by weight, sucrose: 10.392% by weight, salt: 0.5% by weight, milk powder: 2.0% by weight, shortening: 8.0% by weight, Yeast: 1.1% by weight, ice water: 27% by weight. Mix oxidant, flour, sucrose, salt, milk powder, yeast, and ice water, mix and knead evenly, then add shortening and knead until the dough is formed. Finished dough.

[0013] Owing to adding biological oxida...

Embodiment 2

[0015] In the embodiment of the present invention, transglutaminase: 80.7% by weight, ascorbic acid: 0.5% by weight, trehalose: 2.3% by weight, guar gum: 16.5% by weight; transglutaminase, ascorbic acid, seaweed Sugar and guar gum are mixed evenly in a mixing tank in proportion at room temperature, and the rotation speed of the mixer is: 100-120 rpm; then weighed and packaged according to the packaging standard, and refrigerated storage is the finished product of biological oxidant. Refrigeration temperature: 0 ~ 4 ℃.

[0016] In the embodiment of the present invention, the biological oxidant is: 0.009% by weight, flour: 51% by weight, sucrose: 10.391% by weight, salt: 0.5% by weight, milk powder: 2.0% by weight, shortening: 8.0% by weight, Yeast: 1.1% by weight, ice water: 27% by weight. Mix oxidant, flour, sucrose, salt, milk powder, yeast, and ice water, mix and knead evenly, then add shortening and knead until the dough is formed. Finished dough.

[0017] Owing to addin...

Embodiment 3

[0019] In the embodiment of the present invention, transglutaminase: 81.5% by weight, ascorbic acid: 0.4% by weight, trehalose: 2.1% by weight, guar gum: 16.0% by weight; transglutaminase, ascorbic acid, seaweed Sugar and guar gum are mixed evenly in a mixing tank in proportion at room temperature, and the rotation speed of the mixer is: 100-120 rpm; then weighed and packaged according to the packaging standard, and refrigerated storage is the finished product of biological oxidant. Refrigeration temperature: 0 ~ 4 ℃.

[0020] In the embodiment of the present invention, the biological oxidant is: 0.01% by weight, flour: 51% by weight, sucrose: 10.390% by weight, salt: 0.5% by weight, milk powder: 2.0% by weight, shortening: 8.0% by weight, Yeast: 1.1% by weight, ice water: 27% by weight. Mix oxidant, flour, sucrose, salt, milk powder, yeast, and ice water, mix well, knead, then add shortening and knead until dough is formed. Finished dough.

[0021] Due to adding biological...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com