Method for detecting load current by using signal in work cycle of pulsewidth modulation controller

A load current, pulse width modulation technology, applied in the direction of measuring current/voltage, detecting faulty computer hardware, measuring electrical variables, etc., can solve problems such as power consumption, wasted system, and fan speed cannot be real-time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It is particularly noted here that all illustrations are in simple form and not drawn to scale, and the dimensions are exaggerated to facilitate understanding of the present invention.

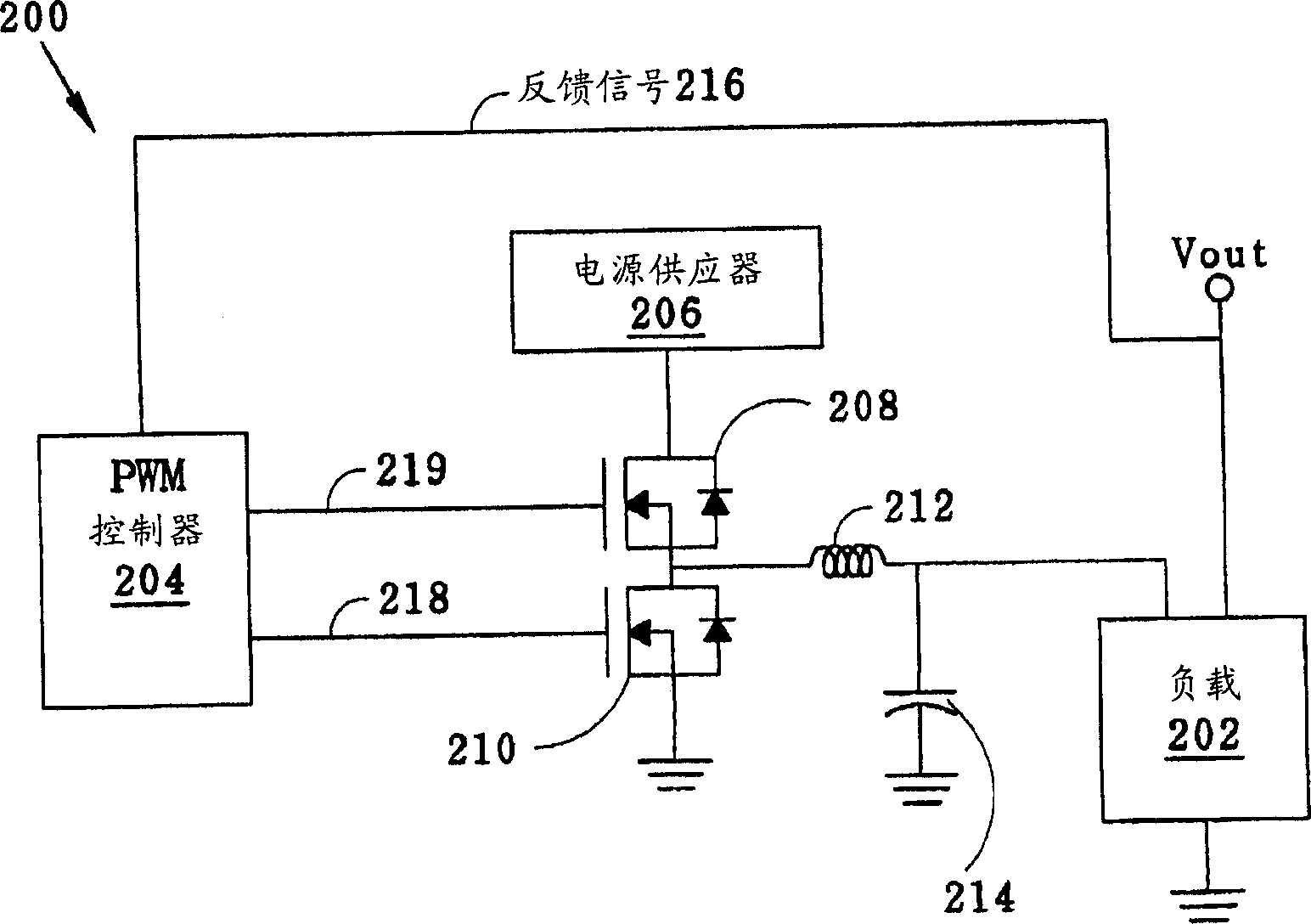

[0048] As shown in Figure 2, it is a schematic diagram of a pulse width modulation switching regulator (PWM switching regulator) circuit 200 according to a basic electronic circuit of the present invention, which includes: load 202 (or electronic components, such as control chips, servers and CPUs, etc. ), a pulse width modulation controller (PWMcontroller) 204, a power supply (power supply) 206, a high side metal oxide semiconductor (high side MOS) 208, a low side metal oxide semiconductor (low side MOS) 210 and an inductor 212 A filter circuit composed of a capacitor 214 and other components, wherein the PWM controller 204 receives a feedback signal 216 from the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com