Miniaturized intelligent differential pressure / pressure transmitter

A transmitter and pressure technology, which is applied in fluid pressure measurement, instruments, and measuring devices using capacitance changes, can solve the problems of high manufacturing cost, single function, and complex structure of capacitive sensor components, so as to facilitate independent detection and reduce Production cost, effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

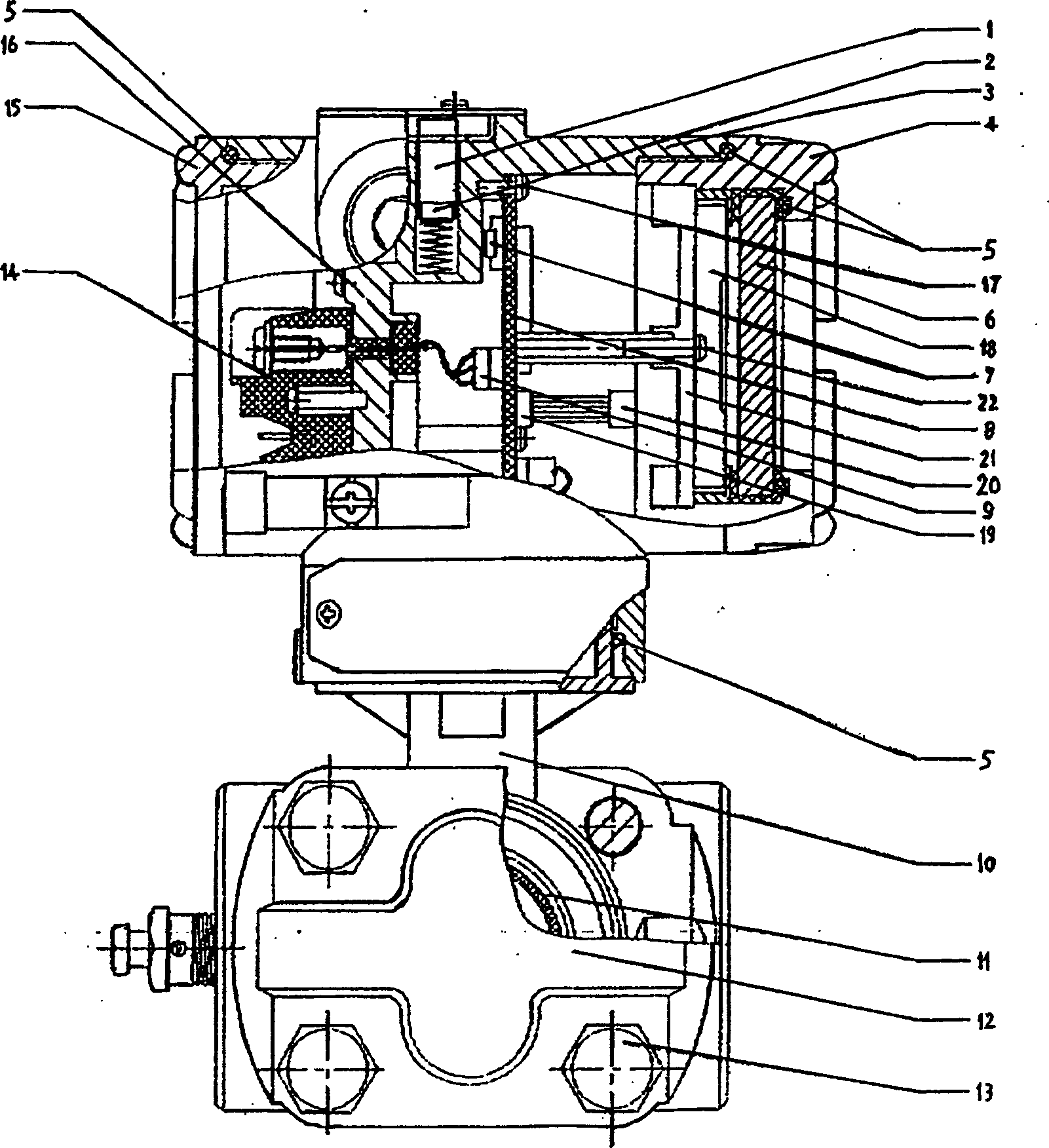

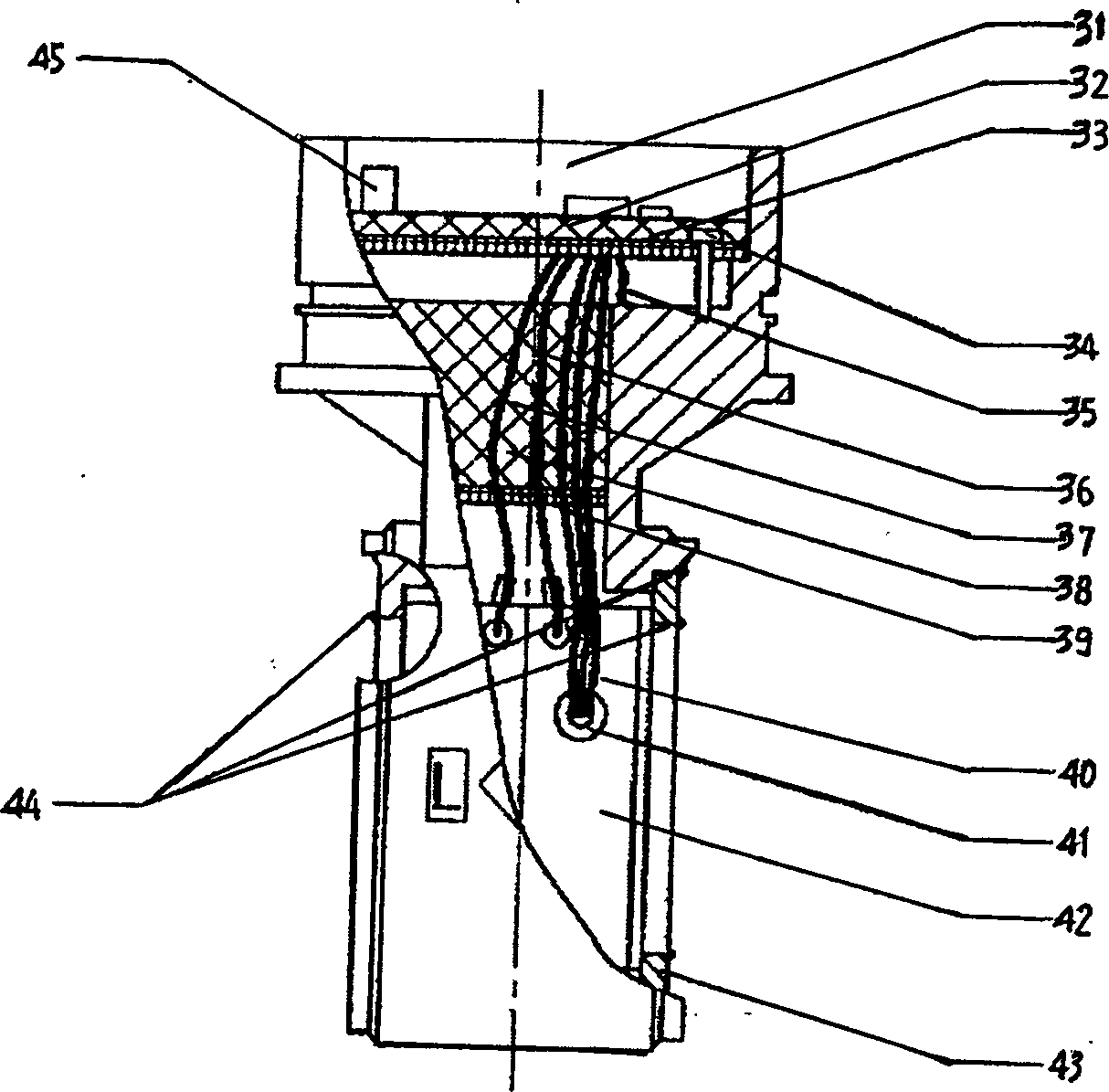

[0024] like figure 1 As shown, the sensor assembly 10 equipped with the pressure sealing ring 11 and the pressure flange assembly 12 are connected together through bolts 13, and the electronic box 3 is installed on the upper part of the sensor assembly 10, which is connected by threads, and the sealing ring 5 is installed in the middle. The inside of the electronic box 3 is divided into two independent chambers, the left side of which is the terminal, and the terminal 14 is arranged for connecting external wires, the right side is the electronic circuit board installation room, and the terminal 14 of the left chamber is The pin leads to the chamber on the right side, and the epoxy resin 16 is used to seal between the pin and the chamber, and a connector 9 is welded on the pin of the terminal 14, which is used for connection with the printed circuit boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com