Actuator control system

A control system and actuator technology, applied in the control system, motor generator control, current controller, etc., can solve the problems of deterioration of durability and high production cost of electric actuators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

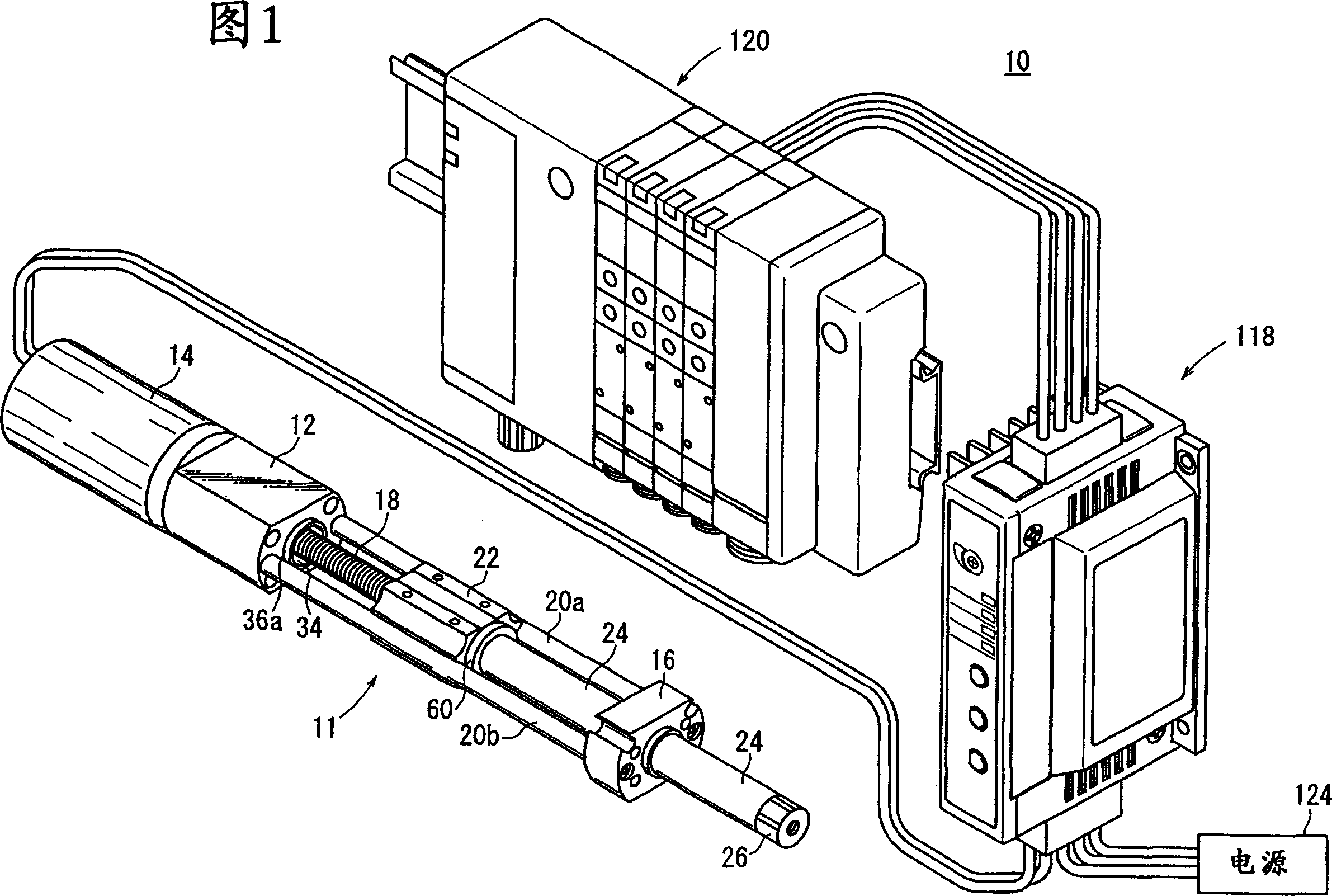

[0077] Referring to FIG. 1, numeral 10 denotes an actuator control system according to an embodiment of the present invention.

[0078] The actuator control system 10 includes an electric actuator 11, wherein the piston 22 and the piston rod 24 perform linear reciprocating motion under the driving action of the rotary drive source 14; The rotary drive source 14; the controller 120, which exports the direction indicating signal to the driver 118; and the power supply 124, which is connected to the driver 118 via a connector.

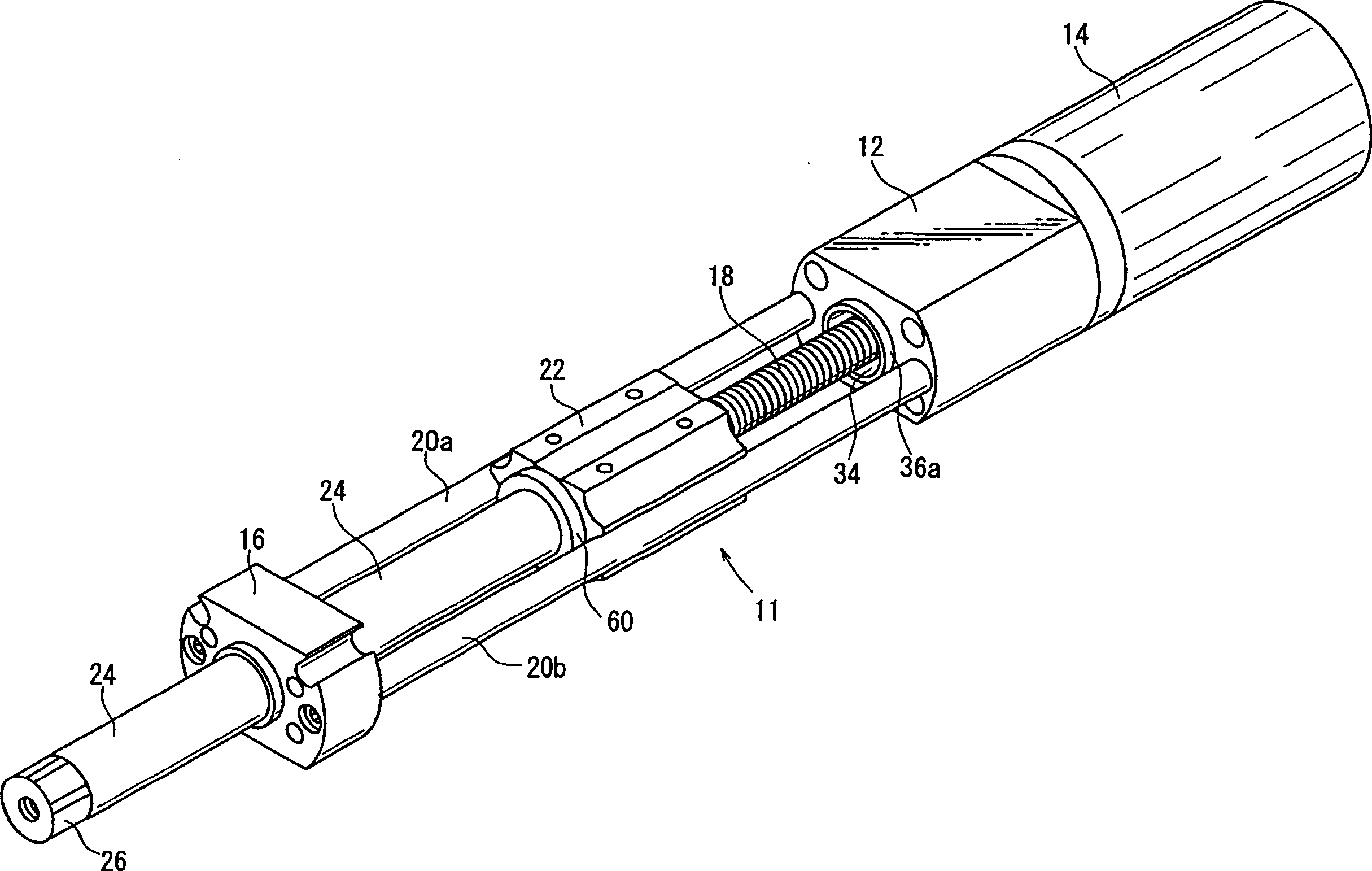

[0079] Such as figure 2 As shown, the electric actuator 11 includes a housing 12, which is composed of a substantially flat block member; a rotary drive source 14, which is connected to one end of the housing 12; a rod housing (end block) 16, which is arranged in relation to the housing. 12 at a predetermined distance, and on the side opposite to the side to which the rotary drive source 14 is connected; and a feed screw shaft (driving force transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com