Tech. for biochemical treating sulphur-containing chark waste water of high concentrating high ammonia nitrogen

A technology for coking wastewater and biochemical treatment, applied in the direction of sustainable biological treatment, multi-stage water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of inability to directly treat coking wastewater, low removal rate of COD and ammonia nitrogen, and wastewater treatment cost Increase and other problems, to achieve the effect of obvious adsorption and removal, stable water output, and save treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

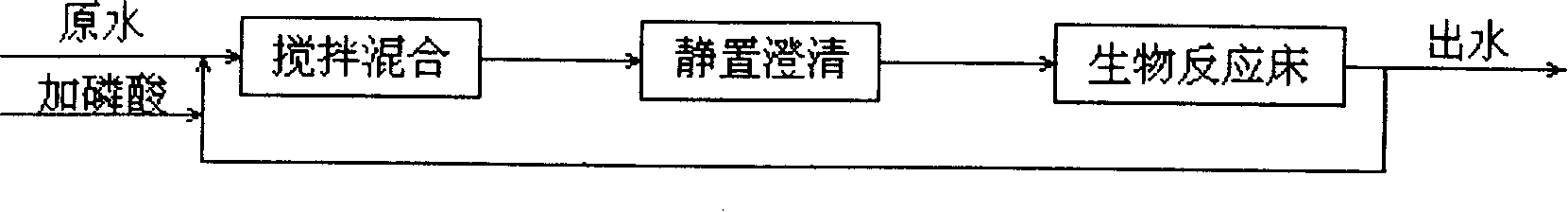

[0021] The following combination figure 1 Describe the specific implementation process of this process:

[0022] A COD of 1900-3400mg / L, NH 3 -N is 1400-2950mg / L, volatile phenol is about 600mg / L, sulfide is 400-888mg / L, cyanide is about 74.3mg / L, pH value is 9.67-9.82 Coking wastewater raw water and treated reflux water Stir and mix at a ratio of 1:1, add phosphoric acid to the reflux water, and adjust the pH of the mixed solution in the mixing tank to about 8.6. The mixing tank adopts the method of gas stirring, and the uniformly mixed wastewater enters the clarification tank to stand for clarification. The clarified wastewater is evenly sprayed or drip-irrigated at a rate of 3-4L / h in a 2.4m-high, 20cm-diameter bed. On the top layer of the 0.5m multi-layer mineralized garbage bioreactor bed, in a one-day operation cycle, water is continuously fed for 3-5 hours, and the rest is the time for the bed to fall freely. The COD of the effluent treated by the reaction bed is gen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com