Integreted tech., or treating yellow ginger processing and waste water

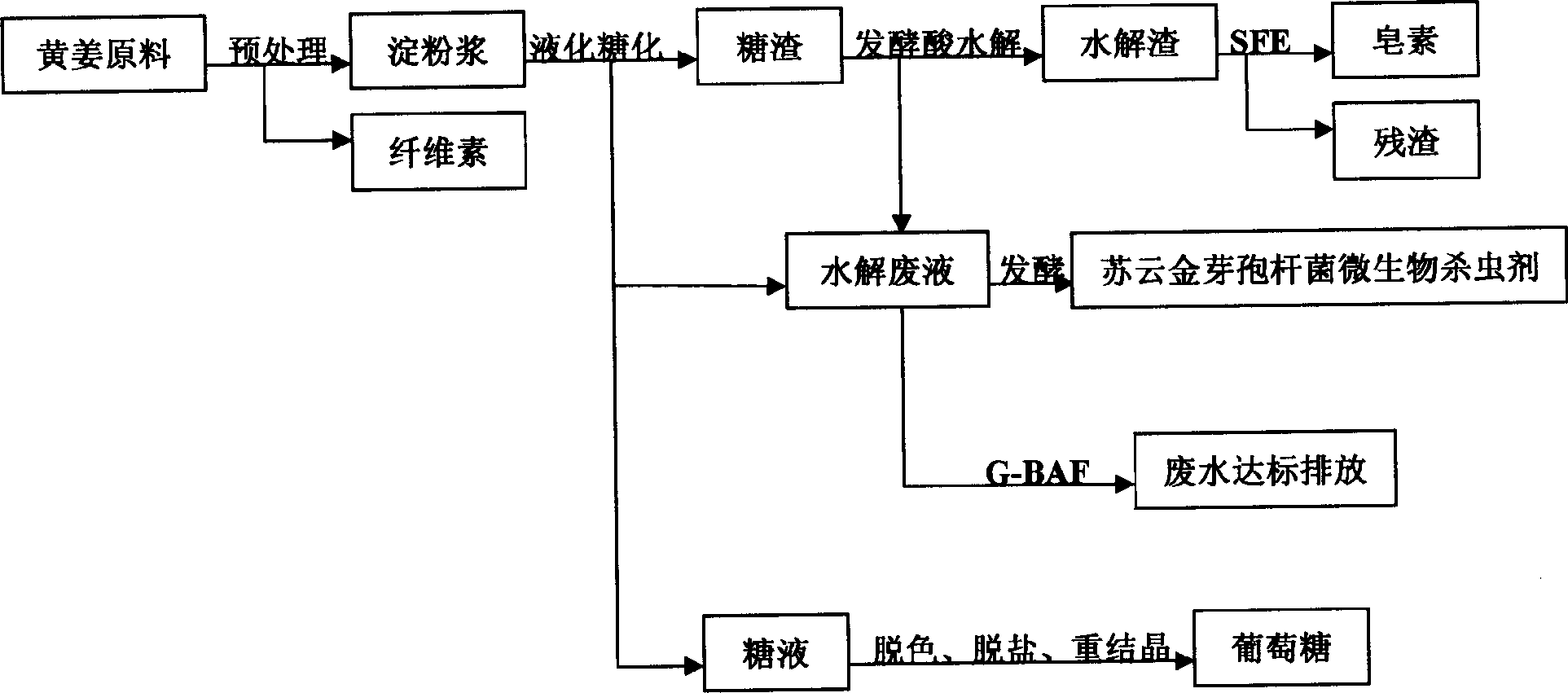

A technology for wastewater treatment and turmeric, applied in water/sewage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of turmeric processing industry pollution, waste of resources, etc., and achieve obvious integration characteristics , the full utilization of resources, the effect of increasing the added value of the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1.2kg of soaked turmeric is pretreated to recover 74% of the total cellulose and 75% of the total starch slurry, and through biological enzymatic conversion, 64% of the starch is converted into glucose products, and the glucose conversion rate is 85% , after acid hydrolysis, the yield of saponin by supercritical extraction process reaches 82%, and the purity of saponin is 94% after testing.

[0050] 62 g of Bacillus thuringiensis microbial insecticide can be obtained through the steps of pretreatment, strain domestication, medium supplementation, seed tank fermentation, fermentation tank fermentation and fermentation liquid post-treatment steps using the hydrolyzed waste liquid produced in the process.

[0051] The technological process produces a total of 500ml of wastewater, the concentration of COD is 46000mg / L, and the concentration of SO 4 2- The concentration is 24600mg / L, NH 4 + -N concentration is 900mg / L, after the high-efficiency microbial treatment of indu...

Embodiment 2

[0053] 1.4kg soaked turmeric is pretreated to recover 75% of the total amount of cellulose and 70% of the total amount of starch slurry, and through biological enzymatic conversion, 66% of the starch slurry is converted into glucose products, and the conversion rate of glucose is 80% %, the yield of saponin by supercritical extraction process after acid hydrolysis reaches 82%, and the purity of saponin is 95% after testing.

[0054] 71g of Bacillus thuringiensis microbial insecticide can be obtained through the steps of pretreatment, strain domestication, medium supplementation, seed tank fermentation, fermenter fermentation and fermentation broth post-treatment steps using the hydrolyzed waste liquid produced in the process.

[0055] The technological process produced a total of 578ml of wastewater, the concentration of COD was 45000mg / L, and the concentration of SO 4 2- The concentration is 24400mg / L, NH 4 + -N concentration is 890mg / L, after the high-efficiency microbial...

Embodiment 3

[0057] 1.3kg of soaked turmeric is pretreated to reclaim 75% of the total cellulose and 72% of the total starch slurry. Through biological enzymatic conversion, 67% of the starch slurry is converted into glucose products, and the glucose conversion rate is 81. %, the yield of saponin by supercritical extraction process after acid hydrolysis reaches 80%, and the purity of saponin is 95% after testing.

[0058] 64 g of Bacillus thuringiensis microbial insecticide can be obtained through the steps of pretreatment, strain domestication, medium supplementation, seed tank fermentation, fermentation tank fermentation and fermentation liquid post-treatment steps using the hydrolyzed waste liquid produced in the process.

[0059] The technological process produces a total of 550ml of wastewater, the concentration of COD is 46000mg / L, and the concentration of SO 4 2- The concentration is 24700mg / L, NH 4 + -N concentration is 900mg / L, after the high-efficiency microbial treatment of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com