System and method for identifying changing of workpiece parameter

A technology for parameter changes and workpieces, applied in electrical components, manufacturing tools, metal processing equipment, etc., to solve problems such as missing end points, weak signals, and ambiguity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

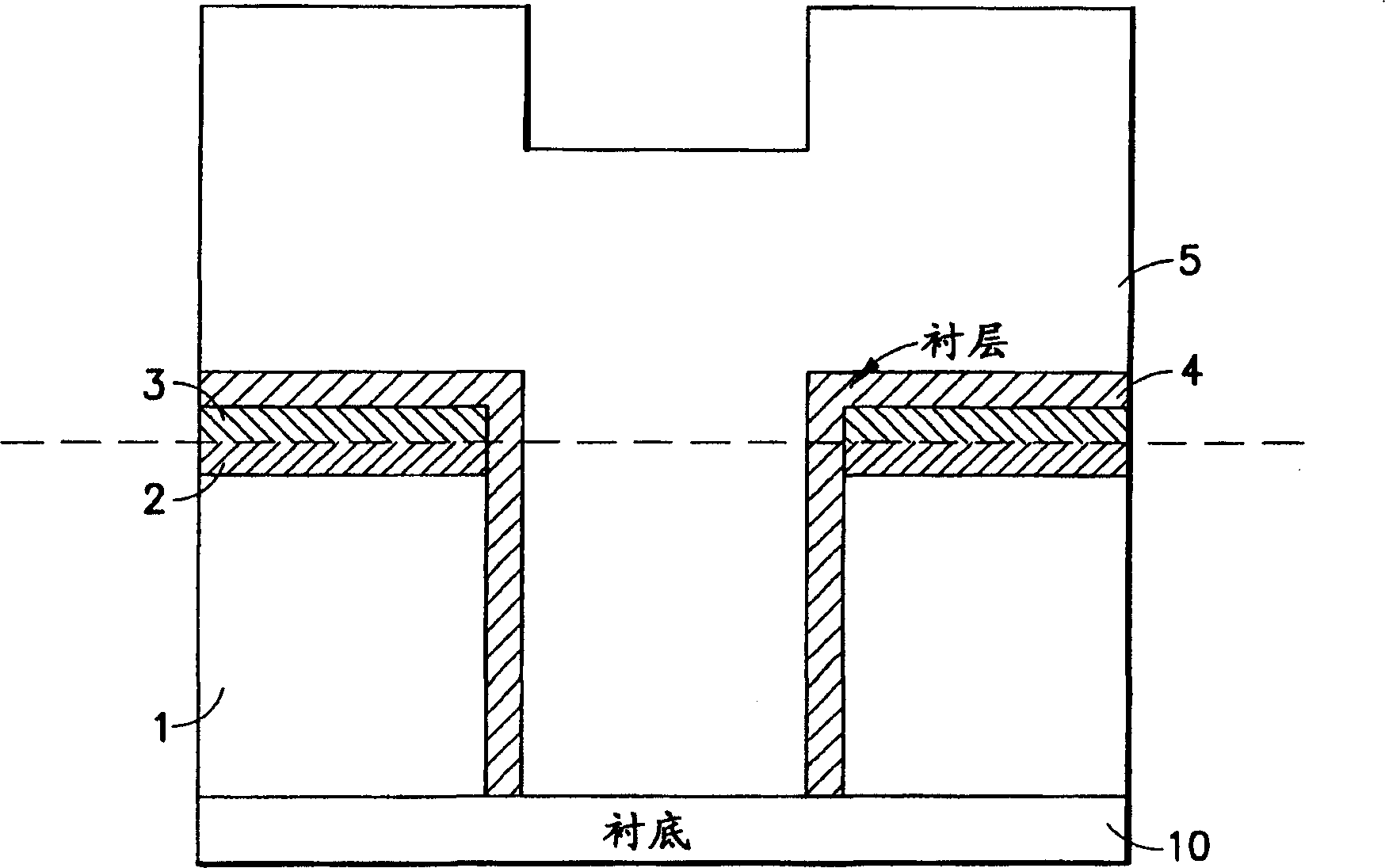

[0021] See figure 1 , the semiconductor structure has a first dielectric layer 1 and hard mask / CMP polish stop layers 2 and 3 . The interface between layer 3 and layer 2 is the interface to be detected or set as a stop point. Depending on the application, the fill material can be metal or dielectric.

[0022] The present invention is directed to the detection of CMP end points when polishing layers of chemically similar material, for example comprising a first dielectric of single damascene or dual damascene thickness (or multiple layers comprising embedded etch stop layers dielectric stack), and a multilayer spin-on or plasma-enhanced chemically vapor deposited (PECVD) CMP stop layer (or "capping layer") on the first dielectric layer "(cap layer)). The first dielectric layer may consist of the following substances: SiLK TM , GX-3 TM , Porous SiLK (TM) , GX - threesome (TM) , Black Diamond TM , NCS TM or other non-porous or porous low-k dielectric materials. The CMP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com