Positive pressure method for detecting filter fabric performance

A detection method and filter cloth technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of pipeline lint blockage, pipeline blockage, heavy weight, etc., to ensure long-term normal operation and large detection pressure difference , the effect of wide detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

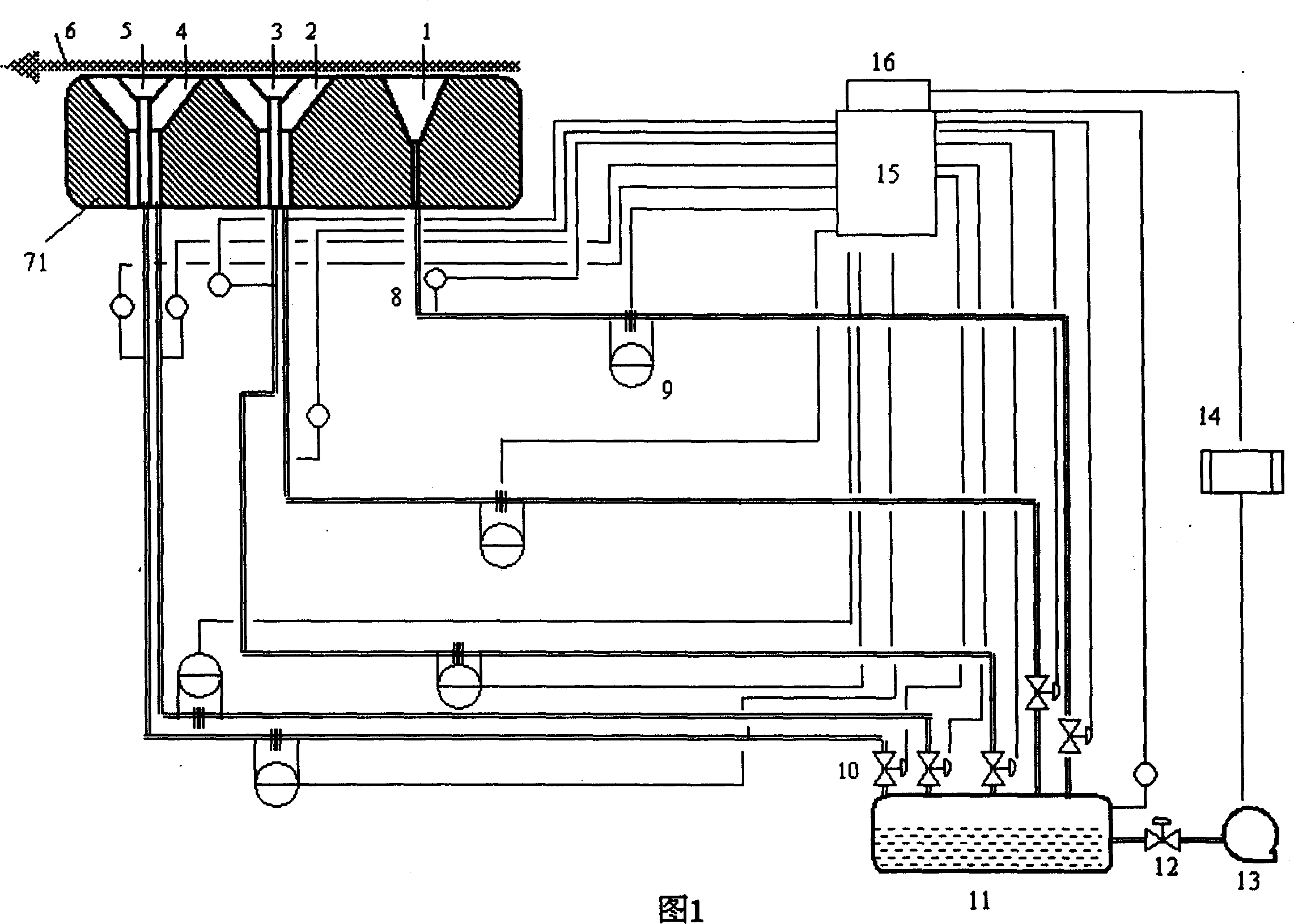

[0032] The detection system adopted by the filter cloth performance positive pressure detection method of the present invention is a positive pressure detection system, which is mainly composed of a probe, a sealing device between the filter cloth and the probe, a pressure sensor 8, a flow sensor 9, a pressure regulating valve 10, a surge tank 11, a compression Pump, controller 15 and power supply form. Referring to accompanying drawing 1, the probe of the detection system of the present embodiment adopts the No. 1 probe 71 that is arranged longitudinally along the filter cloth 4 into five air pressure independent, controllable detection areas 1-5, and there are five independent detection areas 1-5 The two detection areas are the closed second ring-shaped detection area 2 and the fourth ring-shaped detection area 4, and these two ring-shaped detection areas 2, 4 form closed planes to the third detection area 3 and the fifth detection area 5 respectively. Surrounded; five detec...

Embodiment 2

[0044] Referring to Fig. 2, the probe of the detection system of the present embodiment selects No. 2 probe 72, and the probe 72 is arranged longitudinally along the filter cloth 4 into three air pressure independent, controllable detection areas 1-3, wherein the second detection area 2 is a closed The ring-shaped detection area forms a closed plane surrounding the third detection area 3, and the detection area of the first detection area 1 is 100mm 2 , the detection area of the second detection zone 2 is also 100mm 2 , the detection area of the third detection zone 3 is 10mm 2 . The three detection zones 1-3 are equipped with three pressure sensors 8 and three flow sensors 9 .

[0045] Other components and connections of the detection system in this embodiment are the same as those in Embodiment 1.

[0046] The detection method of this embodiment is used when the felt and wet paper are just separated on the press section of the paper machine in the paper mill, and th...

Embodiment 3

[0052] see image 3 , the probe of the detection system in this embodiment selects No. 3 probe 73, and the probe 73 is arranged longitudinally along the filter cloth 4 into two air pressure independent, controllable detection areas 2, 3, wherein the second detection area 2 is a closed ring The detection area forms a closed plane surrounding the third detection area 3, and the detection area of the second detection area 2 is 100mm 2 , the detection area of the third detection zone 3 is 10mm 2. The two detection zones 2, 3 are equipped with two pressure sensors 8 and two flow sensors 9.

[0053] Other components and connections of the detection system in this embodiment are the same as those in Embodiment 1.

[0054] The specification used in the solid-liquid separation of domestic sludge by the detection method of this embodiment is 380 g / m 2 Polypropylene filter cloth 4, the surface of the filter cloth is smooth, and the performance indicators that need to be known most...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com