On-line accurate positioning device and method in heating furnace plate blank

A technology of precise positioning and heating furnace, applied in the direction of heat treatment furnace, furnace, furnace type, etc., can solve the problems of delaying production, crashing the roller table, etc., and achieve the effect of preventing false triggering of signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

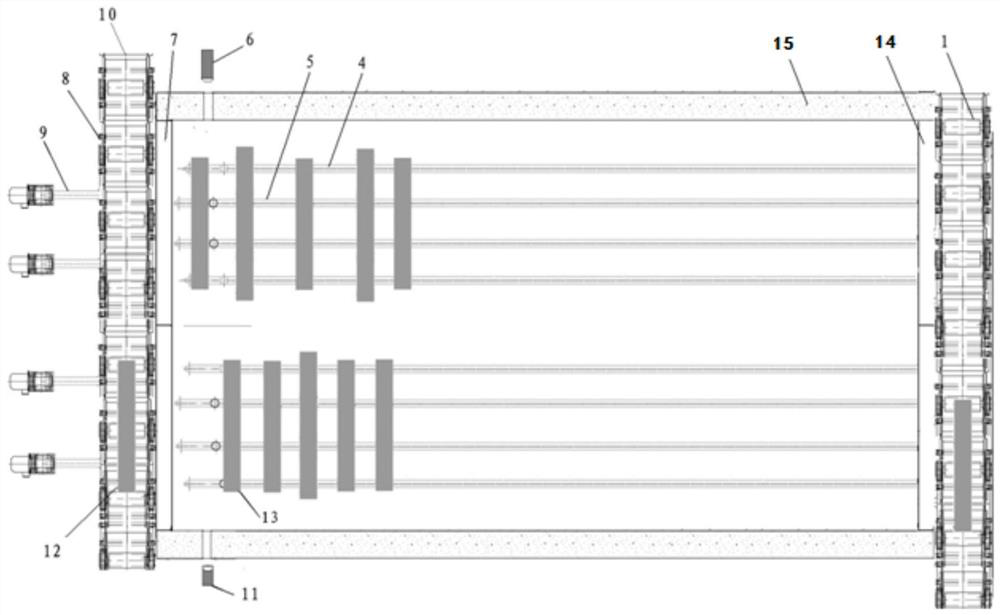

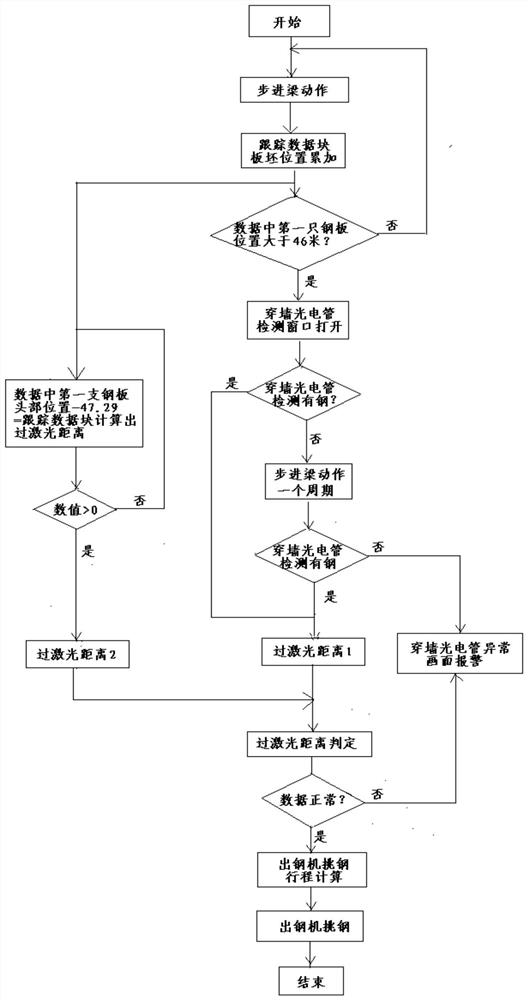

[0023] Take the wide and thick plate regenerative walking heating furnace with a furnace length of 49.50 meters as an example. like figure 1 and 2 As shown, the present invention comprises walking beam, laser photoelectric tube 2 through furnace wall, walking beam magnetic ruler 3 and encoder; The furnace wall laser photoelectric tube 2 includes the wall-penetrating laser photoelectric tube transmitting end 6 and the wall-penetrating laser photoelectric tube receiving end 11, and is respectively located on both sides of the preset position at the end of the walking beam, and is located at a distance of 47.29 meters from the entrance of the heating furnace The walking beam magnetic ruler 3 is installed on the transmission cylinder of the walking beam; the tapping machine 9 is arranged at the exit of the heating furnace; the encoder is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com