Friction wear test method and apparatus for cylinder liner piston ring component

A friction and wear test, piston ring technology, applied in the testing of mechanical components, testing of machine/structural components, testing of wear resistance, etc., can solve the problems of long test period, high cost, increased test period and test cost, etc. Achieve the effect of easy expansion, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

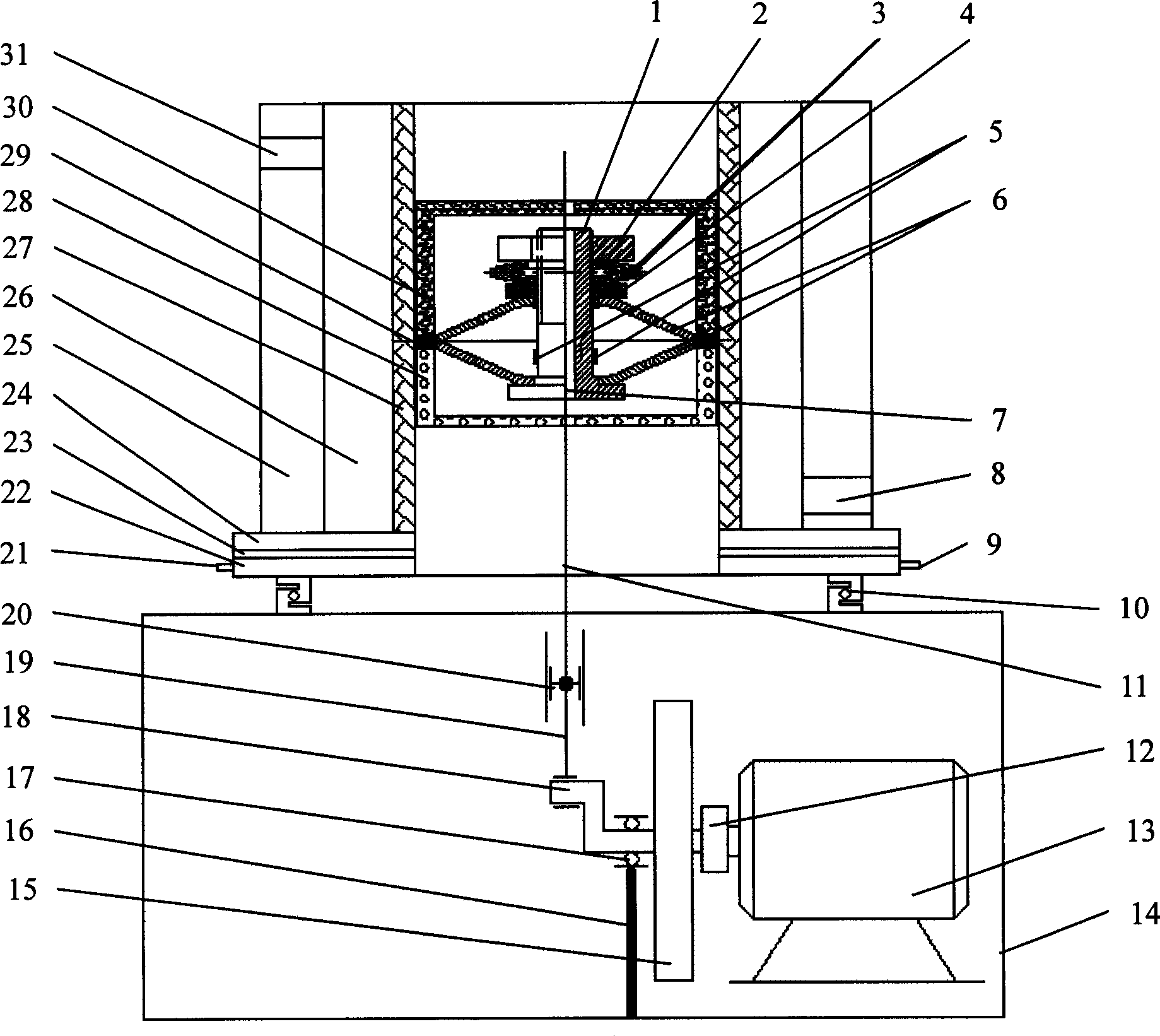

[0027] The outer diameter of the nut 2 is 40mm, the inner hole is an M16mm thread, and the thread of the nut 1 is matched with the thread on the top of the elastic screw 1;

[0028] The outer diameter of the connection between the lower part of the nut 2 and the disc spring 3 with an outer diameter of 56mm, an inner diameter of 28.5mm, a wall thickness of 3mm, a height of 4.3mm, a maximum displacement of 1.3mm, and a maximum load of 11400N is 28.5mm. The height of the boss is 5mm;

[0029] The outer diameter of the intermediate flange of the positioning sleeve 4 is 35mm, the thickness is 5mm, the diameter of the middle hole is 16mm, the outer diameters of the upper and lower connecting parts are 28.5mm and 24mm respectively, and the height of the bosses of the upper and lower connecting parts is 5mm.

[0030] The outer diameter of a pair of equivalent disc levers 6 is 97mm, the inner diameter is 24mm, the thickness t=3mm, and the bottom angle θ=30°; the disc levers 6 are slit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com