Method and apparatus for treating contaminated salt

A treatment method and technology for polluted salt, which are applied in combustion methods, lighting and heating equipment, alkali metal chlorides, etc., can solve problems such as environmental pollution and resource waste, and achieve the effects of prolonging residence time, saving energy consumption, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

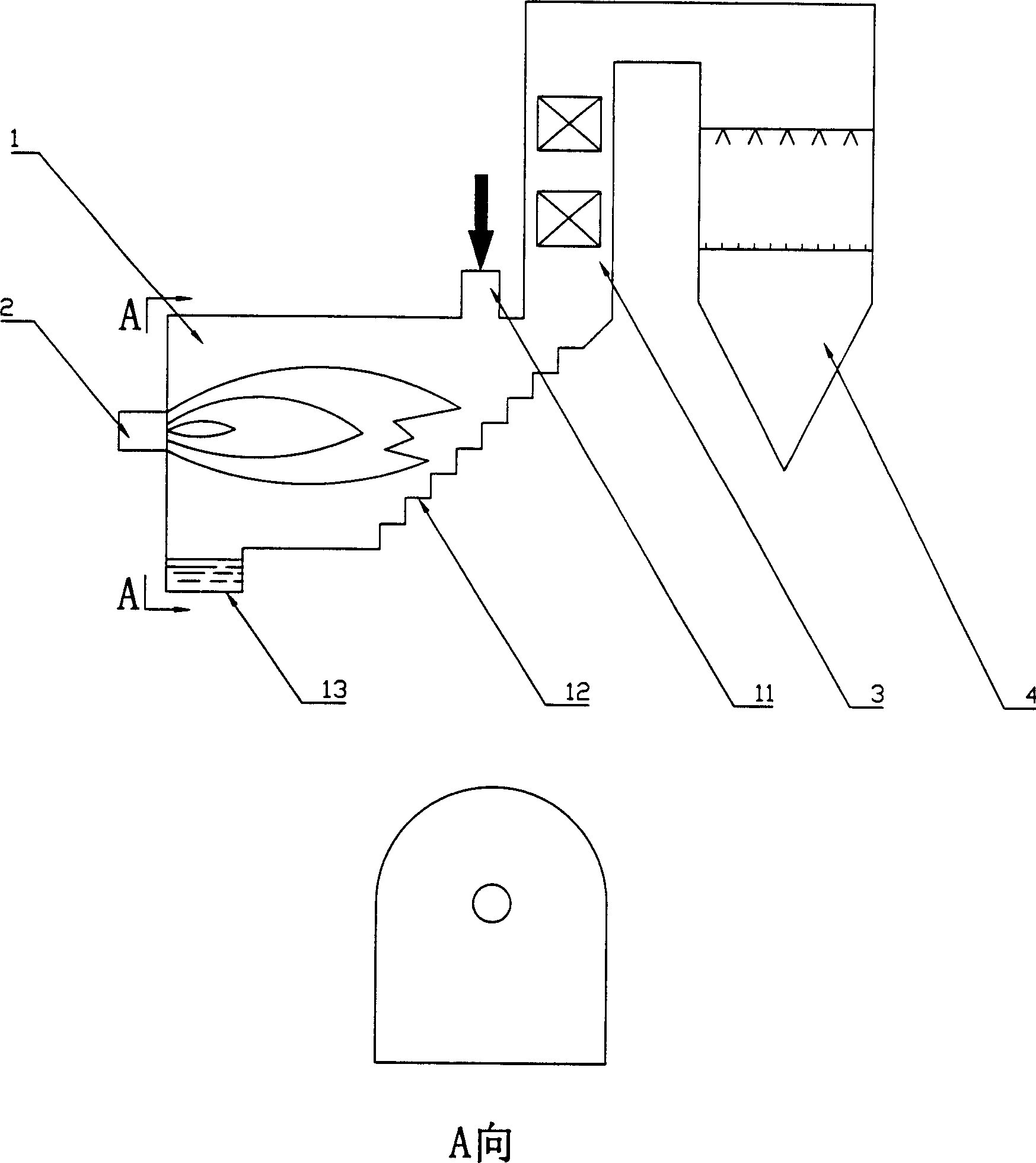

[0020] A pollution and salt harmless treatment device, including a furnace 1, a burner 2, a tail flue 3 and a flue gas washing and purification tower 4. The furnace 1 is arched below the upper circle, and the front wall is aligned with the middle of the rear wall. Burner 2, the rear wall 12 is in the shape of a ladder shrinking toward the bottom of the furnace, the top of the furnace 1 is provided with a dirty salt inlet 11 near the rear wall, the bottom of the furnace 1 is provided with a molten salt collection pool 13, the top of the furnace 1 and the tail flue 3 connected; the air excess coefficient in the furnace 1 is 1.5, and the temperature of the furnace is 850°C. The flame of oil burning goes straight to the rear wall 12, melting the dirty salt sliding down the rear wall 12, and flows into the molten salt collection pool 13. The harmful pollutants in the dirty salt The organic matter is oxidized and decomposed, and the flue gas enters the flue gas washing and purificati...

Embodiment 2

[0022] A pollution and salt harmless treatment device, including a furnace 1, a burner 2, a tail flue 3 and a flue gas washing and purification tower 4, the furnace 1 is an arch below the upper circle, the natural gas burner 2 is installed on the front wall, and the rear wall 12 It is a ladder shape that shrinks toward the bottom of the furnace. The top of the furnace 1 is provided with a dirty salt inlet 11 near the rear wall 12. The bottom of the furnace 1 is provided with a molten salt collection pool 13. The top of the furnace 1 is connected to the tail flue 3; the air in the furnace 1 The excess coefficient is 1, the furnace temperature is 900°C, and the flame of natural gas combustion goes straight to the back wall 12, melting the dirty salt sliding down the back wall 12 and flowing into the molten salt collection pool 13, where the harmful organic matter in the dirty salt is oxidized and decomposed, and the flue gas The flue gas enters the flue gas washing and purificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com