Biomass combustion device with low NOx emission and combustion method thereof

The technology of a combustion device and combustion method is applied in the direction of solid fuel combustion, combustion equipment, lighting and heating equipment, etc. It can solve the problems of poor burnout degree, open-air combustion pollution, and high volatile biomass, so as to reduce black emission High smoke and CO emissions, improved combustion efficiency, and reduced rapid combustion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

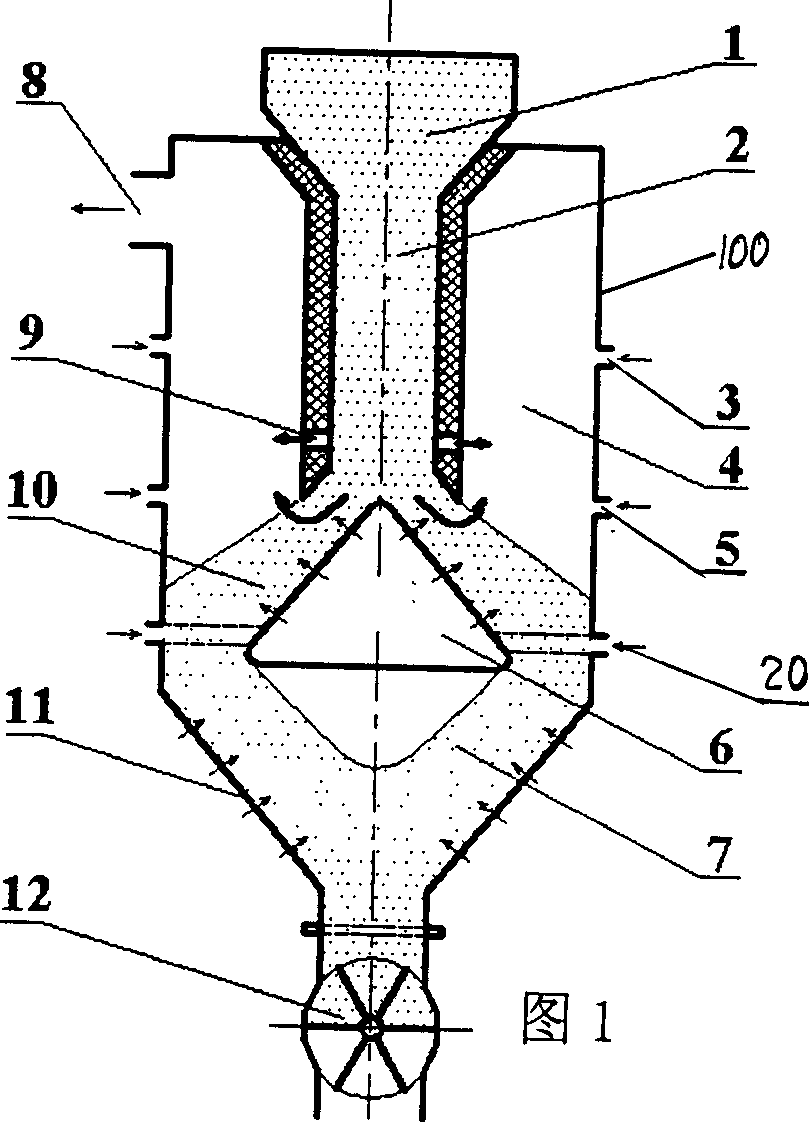

[0032] FIG. 1 is a schematic diagram of the structure of Embodiment 1. FIG.

[0033] The combustion furnace 100 of Embodiment 1 is a straight cylinder, the cylindrical pyrolysis chamber 2 is located in the middle of the furnace, and the lower part is an inverted cone grate 11 connected to a rotary valve type slag tapping device 12. During the combustion process, the feed, slag removal and combustion speed of the biomass fuel are all controlled by the rotary valve type slagging device 12 at the lower part of the furnace. Biomass fuel enters the pyrolysis chamber 2 located in the center of the furnace from the hopper 1 at the upper part of the furnace, and is quickly heated and precipitated volatiles under the action of the heat in the furnace. A part of the separated volatiles enters the combustion chamber 4 through the communication port 9 to burn, and the other part The volatiles along with the coke after fuel pyrolysis enter the reduction zone 10 for combustion along the cone-sh...

Embodiment 2

[0035] Attached image 3 It is a schematic diagram of the structure of Example 2.

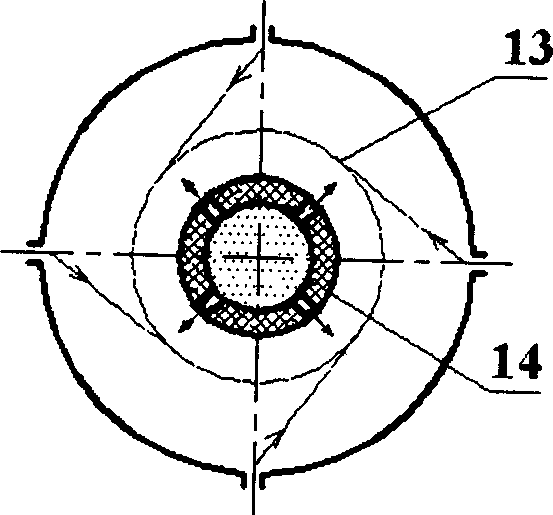

[0036] The cross section of the furnace hearth of Embodiment 2 is rectangular, and the upper part of the furnace hearth is divided into the pyrolysis chamber 2 and the combustion chamber 4 by the partition plate 14. Two-layer inclined grate such as image 3In the arrangement shown, the feed, slag removal and combustion speed of the biomass fuel are all controlled by the screw conveyor 12 at the lower part of the furnace. Biomass fuel enters the pyrolysis chamber 2 from the hopper 1 in the upper part of the furnace, and is quickly heated to separate volatiles under the action of the heat in the furnace. Part of the separated volatiles enters the combustion chamber 4 through the communication port 9 and burns, and the other part of the volatiles follows the fuel. The pyrolyzed coke enters the reduction zone 10 along the upper inclined grate 16 and burns. In the reduction zone, the coke and volatile mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com