Method of thermal adherend release and apparatus for thermal adherend release

A peeling device and adherend technology, applied in the direction of adhesives, electric solid devices, semiconductor devices, etc., can solve the problems of semiconductor wafer cracking, falling off, component displacement, etc., to prevent damage and displacement, accurate peeling, prevent productivity or production. rate reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

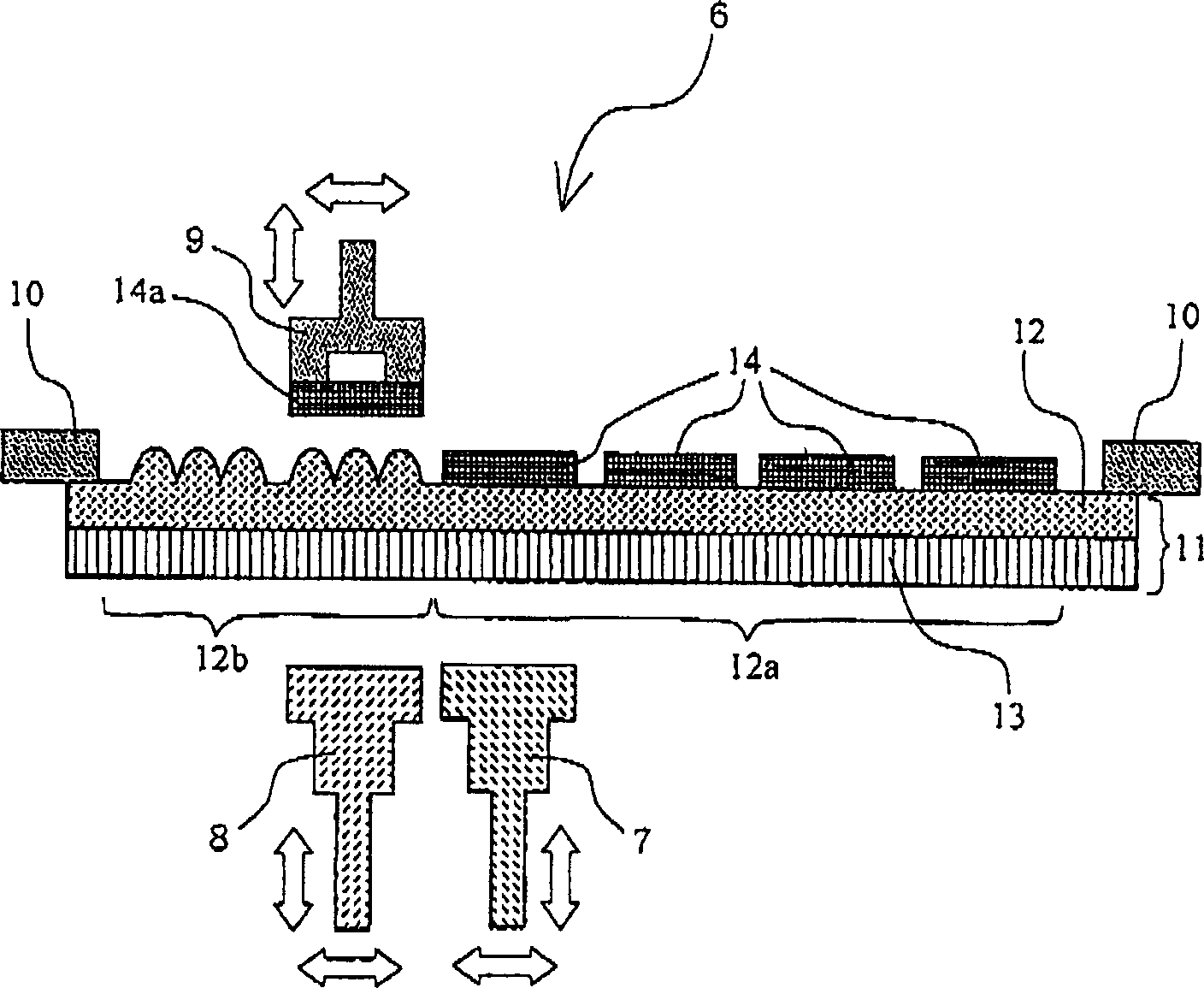

Embodiment 1

[0149] In the case composed of a polyester base material (thickness 100 μm) and a heat-expandable pressure-sensitive adhesive layer (whose peel strength decreases at 90°C (peeling initiation temperature is 90°C)) formed on one surface of the polyester base material In the heat-peelable pressure-sensitive adhesive tape (fixed by a fixing ring), a silicon wafer (thickness 150 µm) having a diameter of 6 inches was adhered to the surface of the heat-expandable pressure-sensitive adhesive layer without introducing air bubbles. Then, the aforementioned silicon wafer was cut into 3 mm size cubes.

[0150] In addition, a preheating zone in which a stainless steel (SUS 304) plate having a size of 3 mm square and a thickness of 2 mm and a thermally conductive rubber sheet (3 mm square and 1 mm thickness) and a stripping and heating zone were respectively prepared as the preheating zone and Peel and heat zone. Then, heating is performed by an electric heater so that the temperature of t...

Embodiment 2

[0154] The silicon wafer slices were peeled off in the same manner as in Example 1, except that a heat-peelable pressure-sensitive adhesive tape having a heat-expandable pressure-sensitive adhesive layer having a peeling start temperature of 120° C. was used as the heat-peelable pressure-sensitive adhesive tape. Sensitive adhesive tape, and use such conditions: the temperature of the rubber sheet portion (leading end portion) in the preheating zone is 105°C, and the temperature of the rubber sheet portion (leading end portion) in the peeling and heating zone is 170°C. In this case, when the slice of the silicon wafer was adsorbed and peeled by the suction nozzle, the time required to peel one slice of the silicon wafer (average time required for peeling) was 1.5 seconds, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com