Self-luminous key, keyboard and manufacturing method thereof

A production method and self-luminous technology, which are applied to electrical components, electrical switches, circuits, etc., can solve the problems of high use cost, waste of energy, light-emitting life, and high cost of light-emitting keyboards, and achieve long light-emitting life, low manufacturing costs and low use costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

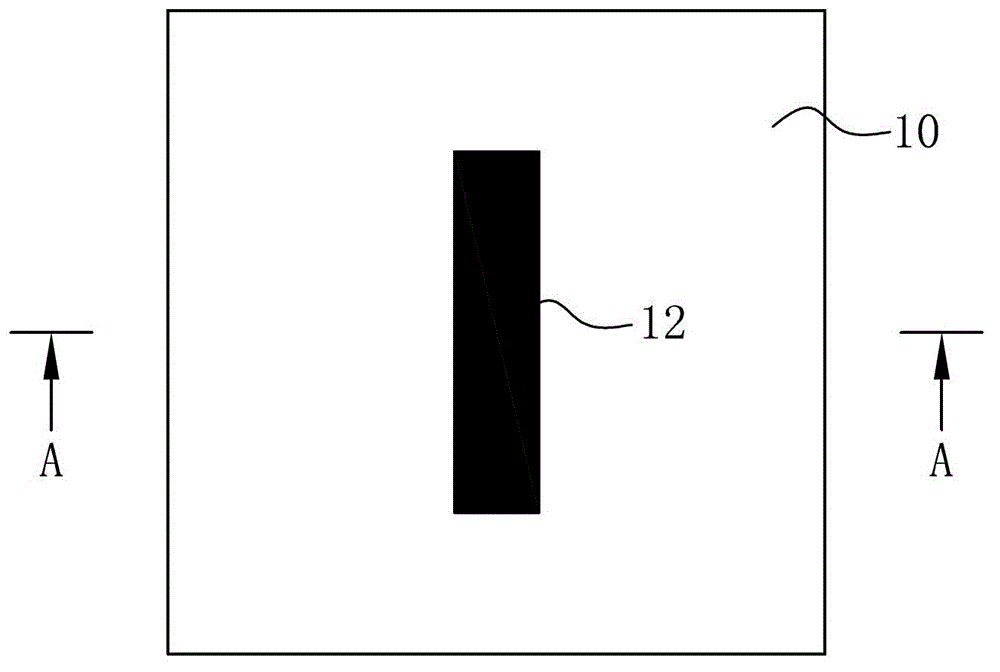

[0050] The present invention also provides a method for making a self-illuminating button, in the first embodiment, which includes the following steps:

[0051] Step 100: forming a body doped with luminescent material keys, the body being light-colored;

[0052] Step 101: Spraying dark paint on the body to form a primer layer;

[0053] Step 102: Laser engraving on the body to form a laser engraving area, exposing corresponding parts of the body to display key symbols.

[0054] The above-mentioned method can be used to manufacture the luminous key, so as to achieve the corresponding effect of the self-luminous key of the present invention.

[0055] In addition, after the step 102, a step 103 may also be included: spraying a transparent protective layer on the primer layer. Thereby the protection to the key is achieved.

[0056] see again Image 6, Image 6 It is a method flowchart of the second embodiment of the manufacturing method of the self-luminous key according to th...

no. 2 example

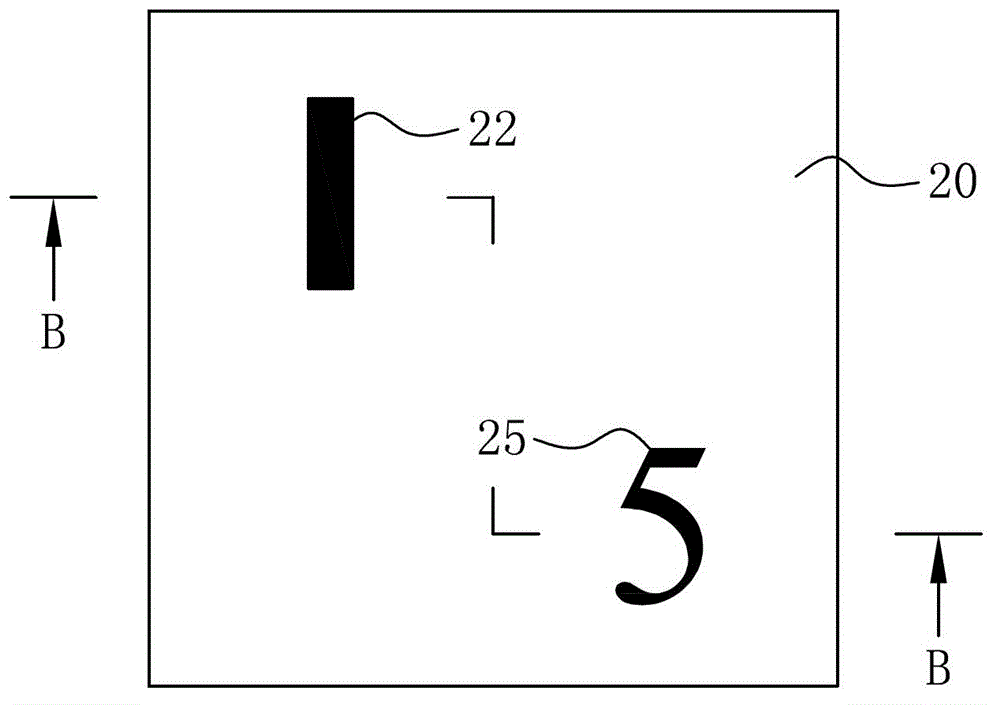

[0057] The present invention also provides a method for making a self-illuminating button, in the second embodiment, which includes the following steps:

[0058] Step 200: forming a body doped with luminescent material keys, the body being light-colored;

[0059] Step 201: spray paint on the body to form a paint layer, the paint is doped with luminescent material;

[0060] Step 202: Spraying dark paint on the body to form a primer layer;

[0061] Step 203: Laser engraving above the body to form a laser engraving area, exposing corresponding parts of the body to display key symbols;

[0062] Step 204: Perform laser engraving on the primer layer to form a colored laser engraving area, exposing corresponding parts of the color paint layer to display color symbols.

[0063] Wherein, the order between the step 203 and the step 204 can be changed.

[0064] In addition, after the steps 203 and 204 are finished, the manufacturing method may further include a step 205: spraying a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com