Micro mirror box for scan probe microscope

A scanning probe and microscope technology, applied in the microscope field, can solve the problems of high vacuum, complex structure, difficult temperature, etc., and achieve the effect of low production cost, small volume, and improved vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

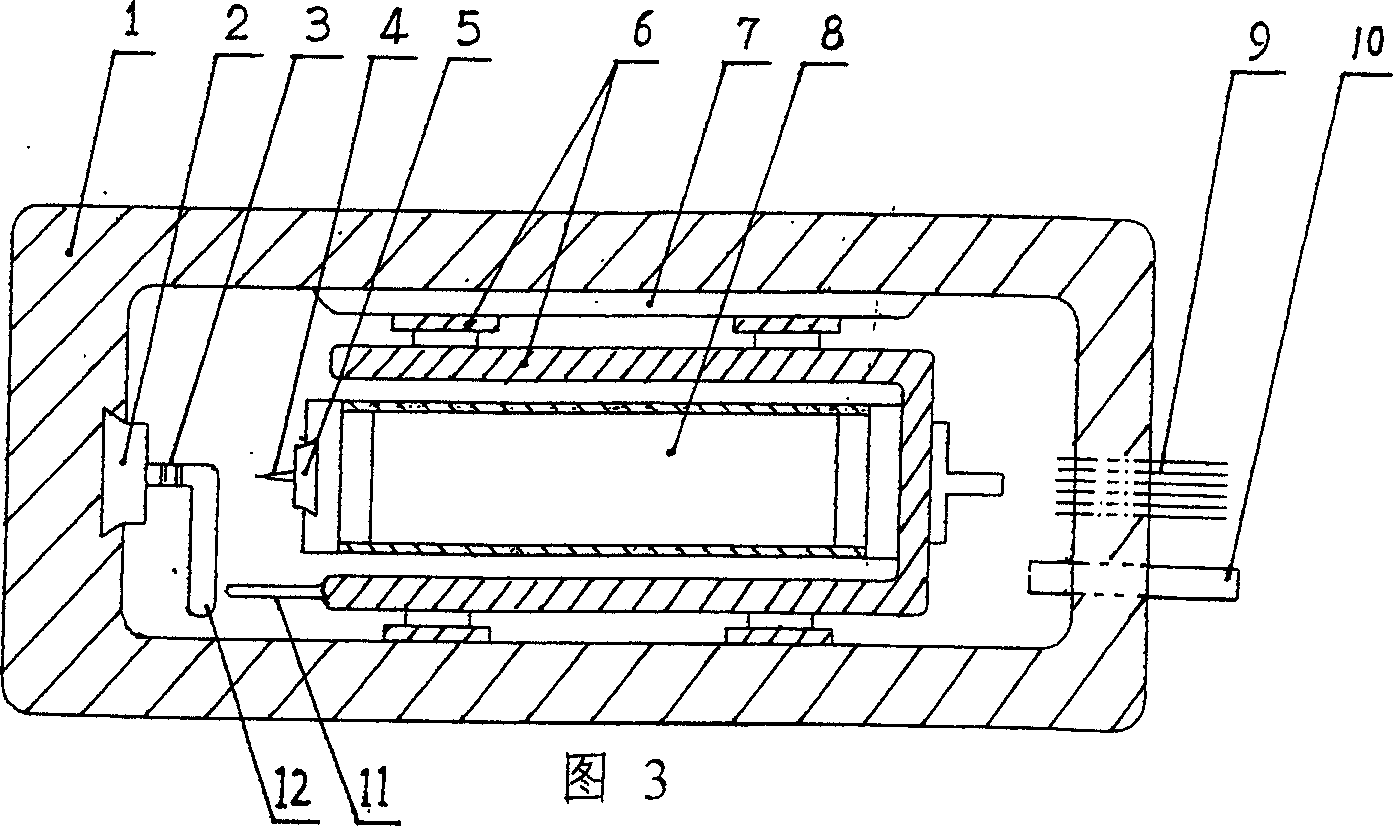

[0020] See attached figure 1 , the sample seat 2 in the figure is set on the inner wall of the box body 1, the communication interface 9 and the air extraction hole 10 are set on the box body 1, the electrostrictive stepper 6 is pressed into the box body 1 through the spring leaf 7, and the electrostrictive stepper 6 is pressed into the box body 1. The rear end of the telescopic scanning tube 8 is fixed on the electrostrictive stepper 6, the probe frame 5 is arranged on the front end of the electrostrictive scanning tube 8, the probe 4 is mounted on the probe frame 5, the signal lines of the probe 4 and The control line of the electrostrictive stepper 6 and the control line of the electrostrictive scanning tube 8 are connected to the communication interface 9 . When in use, the sample 3 to be tested is installed on the sample seat 2 in the box body 1, the probe 4 used is installed on the probe frame 5, and the sealed box cover is covered. The air extraction hole 10 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com