Cylinder head cap for a cylinder head of an internal combustion engine and process for the manufacture of a cylinder head cap

A technology of internal combustion engine cylinder and cylinder head cover, which is applied to the sealing device, mechanical equipment, transportation and packaging of the engine, etc., to achieve the effects of reducing distortion problems, high molding freedom, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The same components in the figures have the same reference symbols.

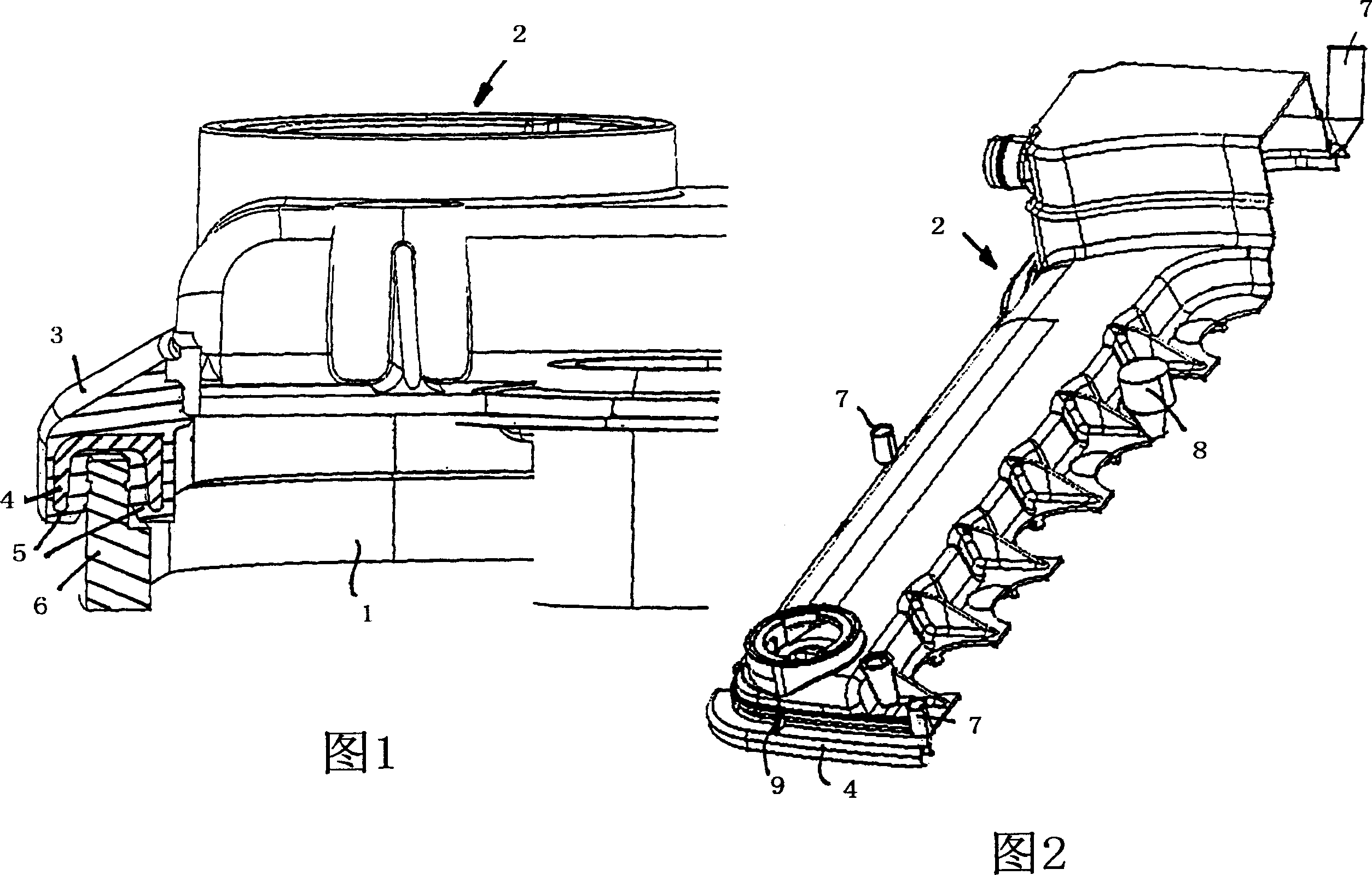

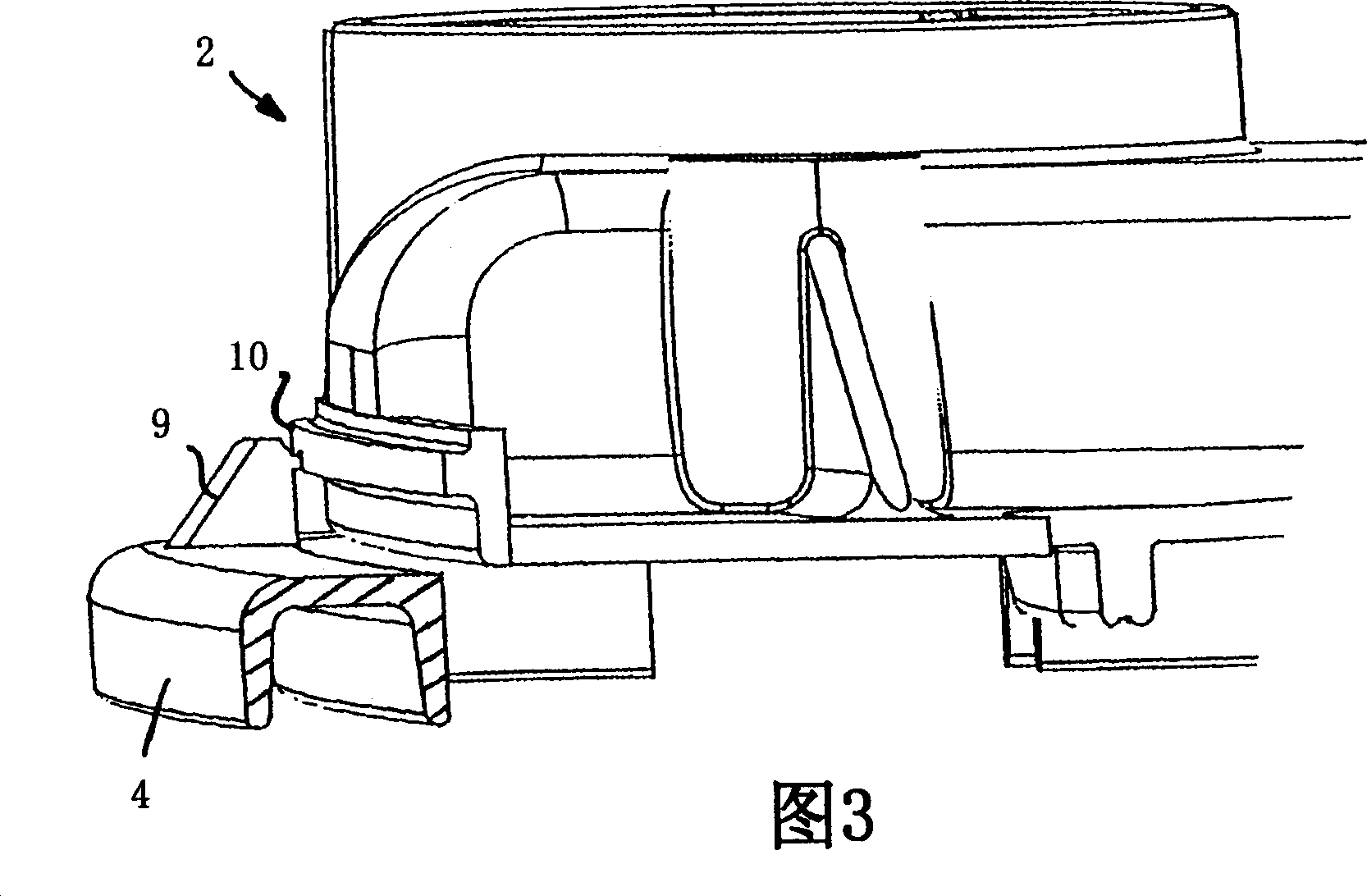

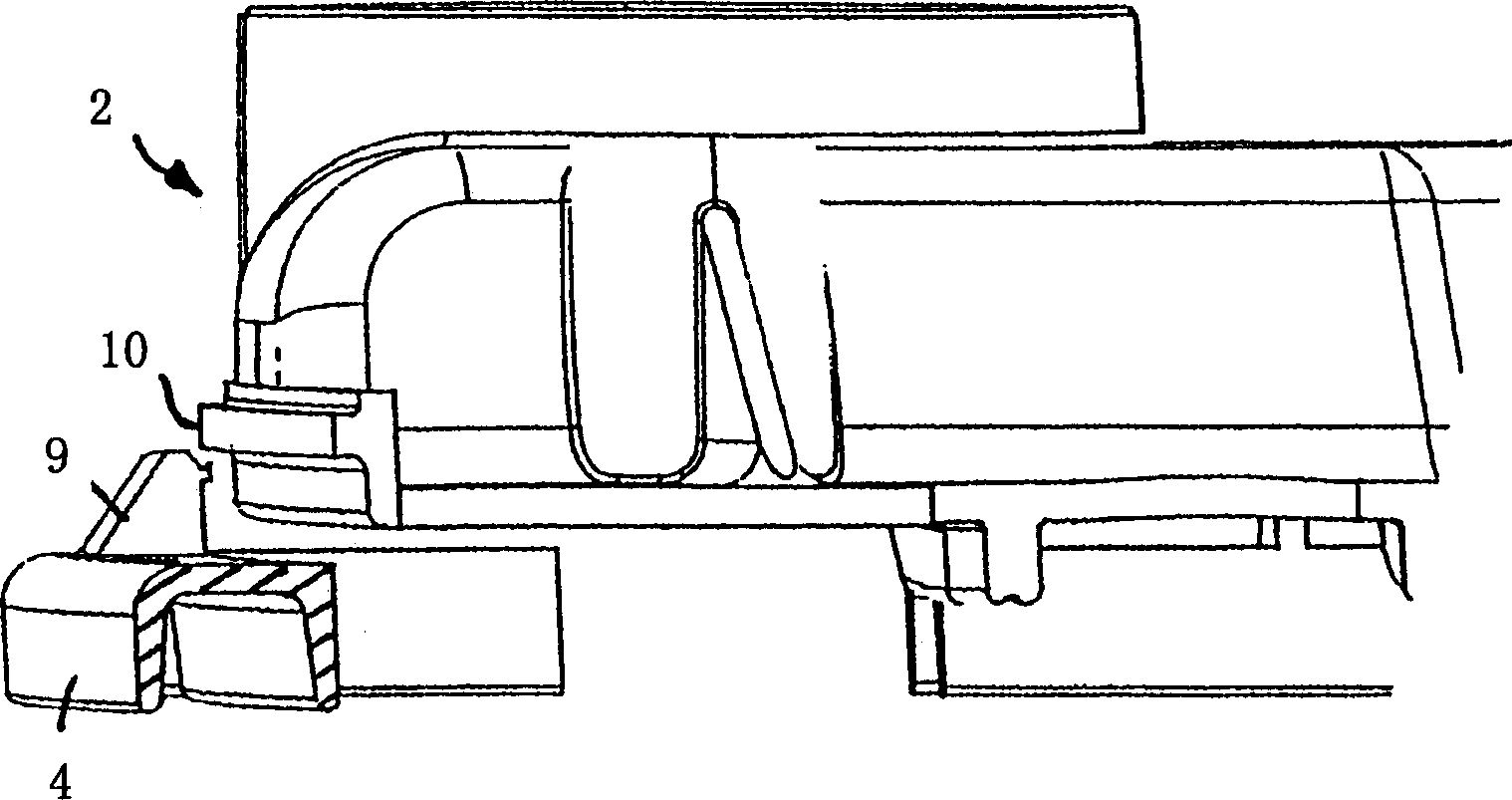

[0022] FIG. 1 shows the upper section of a cylinder head 1 of an internal combustion engine with a cylinder head cover 2 placed thereon. In order to obtain a flow-tight closure between the cylinder head cover 2 and the cylinder head 1 produced as a plastic moulding, there is an annular seal 3 distributed in the region of the outer edge of the cylinder head cover 2 , which is injection-moulded in accordance with the purpose Cylinder head cover 2 on. Inserted in the sealing body of the seal 3 is a likewise annular support ring 4 which consists of the same plastic material as the cylinder head cover 2 . The support ring 4 is U-shaped, wherein the opening in the support ring faces downwards. The support ring 4 is completely surrounded by the material of the seal 3 during the injection molding process in which the seal elastomer is injected onto the support ring 4 . Due to the U-shape of the support rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com