Process for producing high purity dicyclo pentylene

A dicyclopentadiene, production process technology, applied in the production process of dicyclopentadiene, can solve the problems of affecting the speed of depolymerization, low temperature of depolymerization, coking, etc., to reduce coking and increase the speed of depolymerization reaction and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

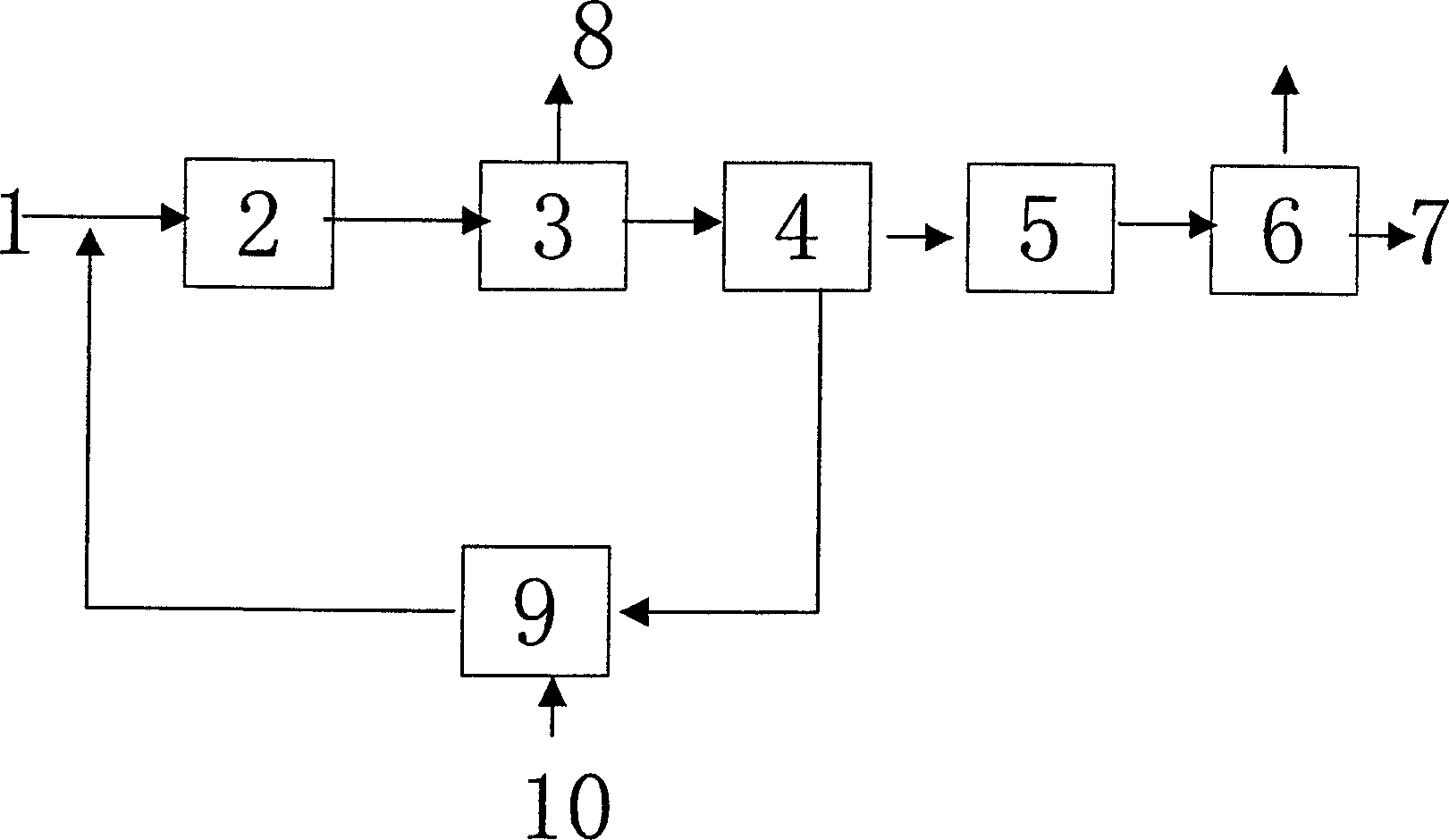

[0032] 400g crude C 5 Cut obtains the thick DCPD 323g that DCPD content is 80.2% after 40 ℃ dimerization 1 hour (process 2) and delight component (process 3); The number of trays in the distillation tower is 10, and the catalyst is SiO after 10% sulfuric acid treatment. 2 , the depolymerization temperature was 150-160°C, and 242g of fractions with a total DCPD+CPD content of more than 99% were obtained; 240g of DCPD with a purity of 99.5% was obtained after entering 100°C dimerization (process 5) and vacuum distillation (process 6).

Embodiment 2

[0034] 400g crude C 5 Cut obtains the thick DCPD 320g that DCPD content is 80.8% after 40 ℃ dimerization 1 hour (process 2) and delight component (process 3); The number of trays in the distillation column is 10, and the catalyst is SiO after 10% hydrochloric acid treatment. 2 , the depolymerization temperature was 150-160°C, and 232g of fractions with a total DCPD+CPD content of more than 99% were obtained; 229g of DCPD with a purity of 99.5% was obtained after entering 100°C dimerization (process 5) and vacuum distillation (process 6).

Embodiment 3

[0036] 400g crude C 5 Distillation is 81.3% crude DCPD334g obtained DCPD content after 1 hour (process 2) and delight component (process 3) of fraction through 40 ℃ of dimerization; The number of trays of the tower is 10, and the catalyst is Al after 10% sulfuric acid treatment 2 o 3 , the depolymerization temperature was 150-160°C, and 255g of fractions with a total DCPD+CPD content of more than 99% were obtained; 251g of DCPD with a purity of 99.5% was obtained after entering 100°C dimerization (process 5) and vacuum distillation (process 6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com