Piping joint for connecting plastic-lining metal pipeline with thin wall and production thereof

A technology for metal pipes and plastic pipe fittings, which is applied in the direction of pipe connection layout, pipes/pipe joints/fittings, pipe components, etc., and can solve the problems of easy aging, complex structure of pipe fittings, aging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below, the present invention is described in further detail in conjunction with accompanying drawing and specific embodiment:

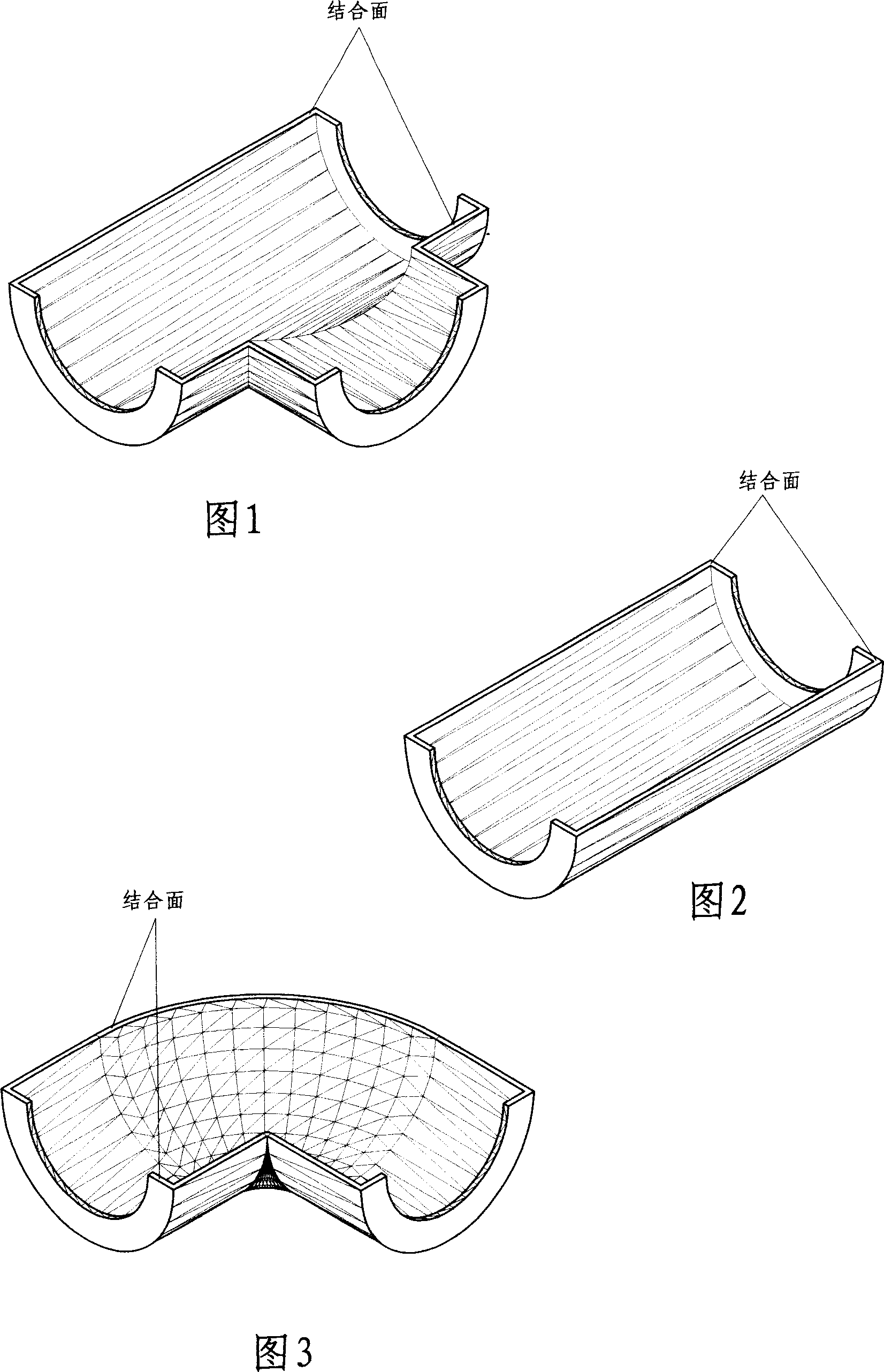

[0014] Fig. 1, Fig. 2, Fig. 3 respectively represent one of the two petals of the metal shells that make up the pipe fittings tee, straight through, and elbows, and the metal shells can be made by stamping and stretching.

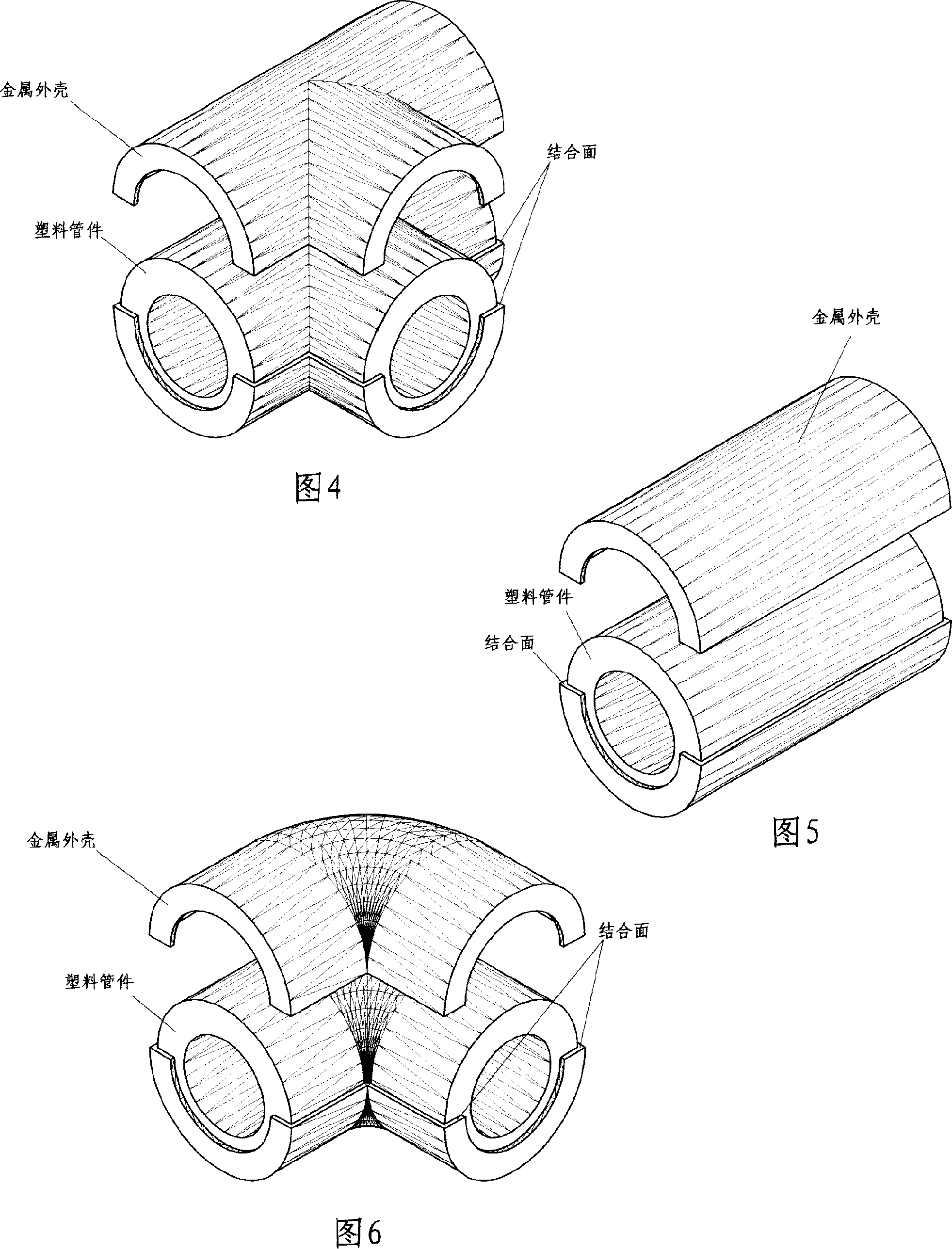

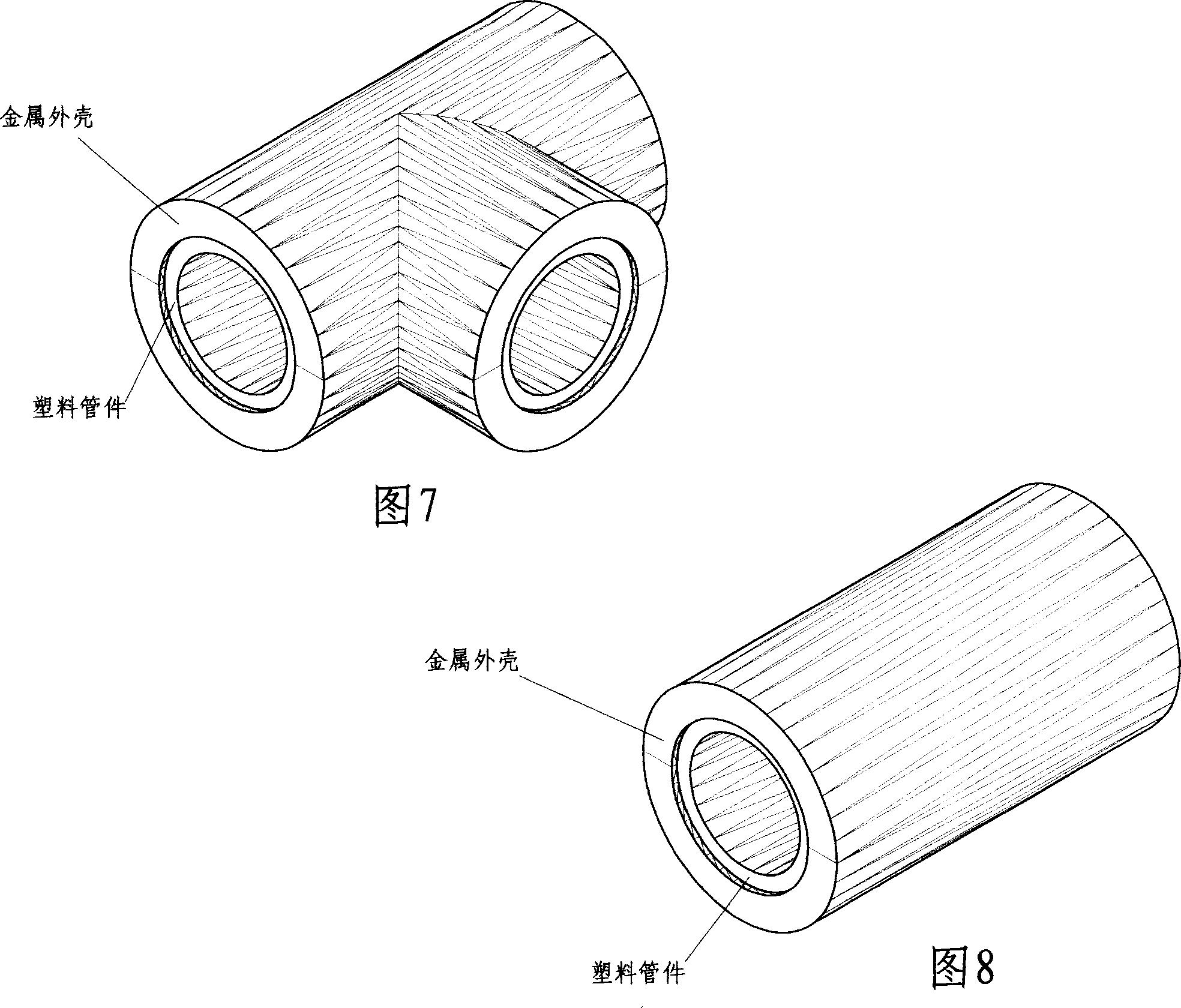

[0015] Fig. 4, Fig. 5, Fig. 6 represent: pipe fittings tee, straight through, elbow, all are made up of two metal shells and plastic pipe fittings wrapped in the metal shells. When making, put the plastic pipe fittings into the metal shell first, and then press the two metal shells tightly so that the joint surfaces of the two metal shells fit together. When bonding the joint surfaces, methods such as butt welding, superglue bonding, and riveting can be used to prevent the joint surfaces from being separated after touching and bonding. The two-petal metal shell is connected into one body through the bonding of the two conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com