New one-step shaping process of carving and diamond-setting for plastic spectacles

A one-time, new technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of unstable product quality, low labor productivity, complex production process, etc., to achieve stable and reliable product quality, high production efficiency, Simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

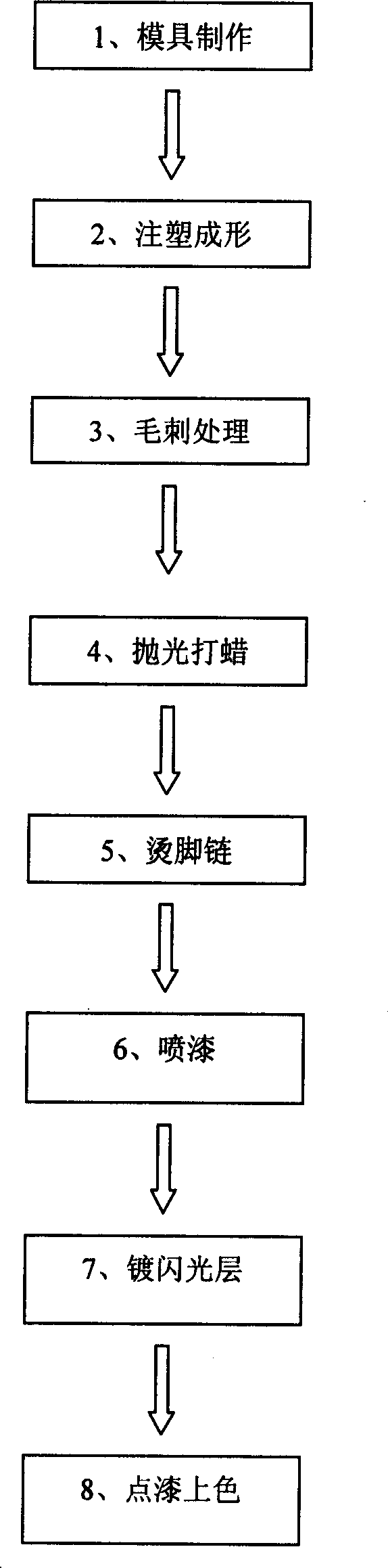

Image

Examples

Embodiment Construction

[0011] As shown in the figure, the process of the present invention includes the mold making of A, mirror frame and tripod, and directly designs decorative patterns and diamond holes in the cavity of the mould; And the diamond hole is directly designed on the cavity of the mold. After the injection molding process, the pattern and the diamond hole are formed on the frame and the tripod at one time. The pattern is designed according to the need, and the diamond hole is a sunken polyhedral Design, in order to be beneficial to produce the effect that is close to the reflected light of diamond; C, carry out polishing and waxing treatment on above-mentioned mirror frame and tripod, polishing process is finished by polishing machine, can finish waxing operation simultaneously in polishing process; D, connect foot The chain is hot-bonded between the above-mentioned mirror frame and the tripod, and the ironing process can be completed by a special anklet machine, which generates high t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com