Reinforced concrete laminated slab

A technology of reinforced concrete and laminated board, applied in the direction of floor, formwork/formwork/work frame, structural elements, etc., can solve the problems of drilling and threading, waste of man-hours, waste of concrete materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

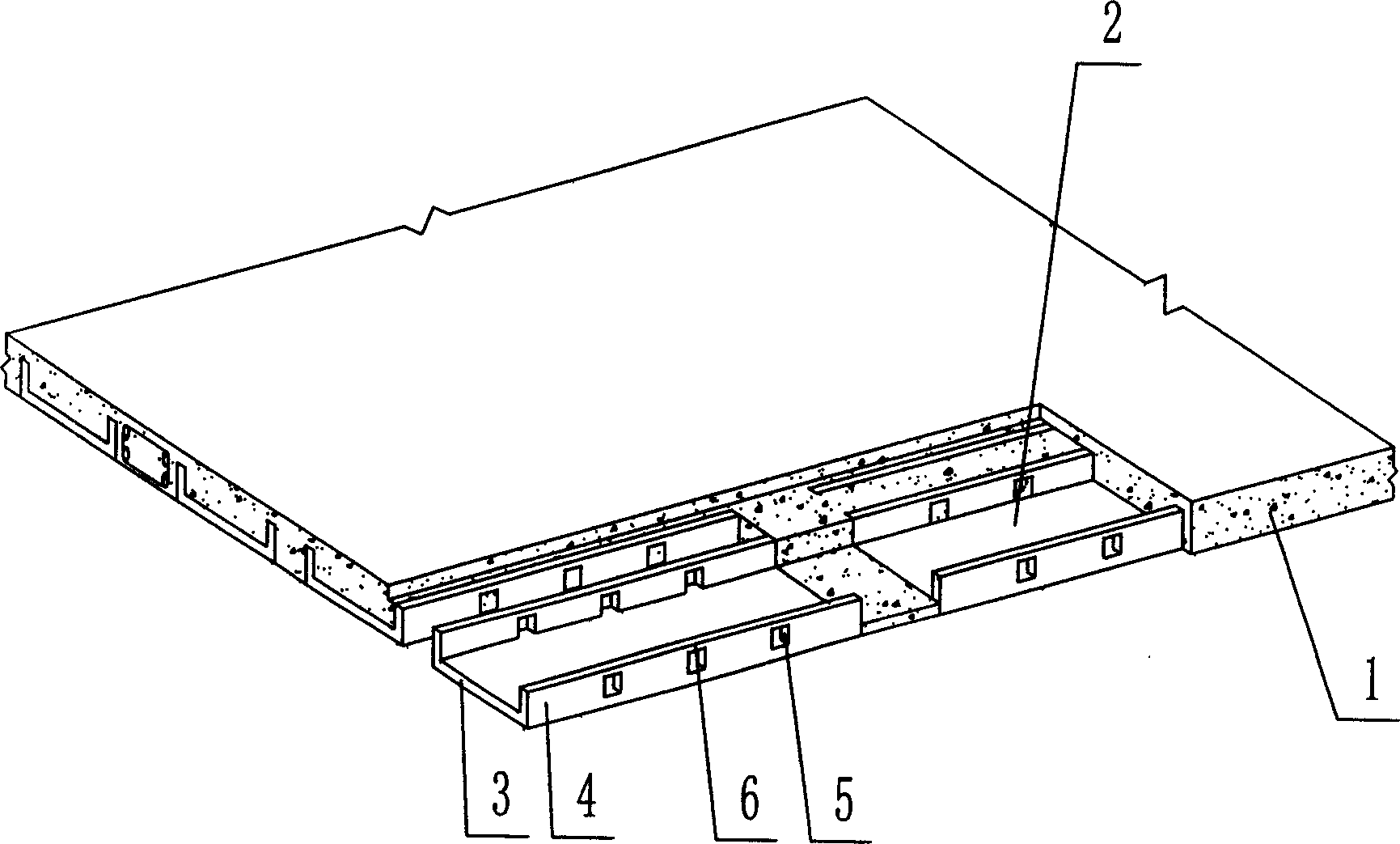

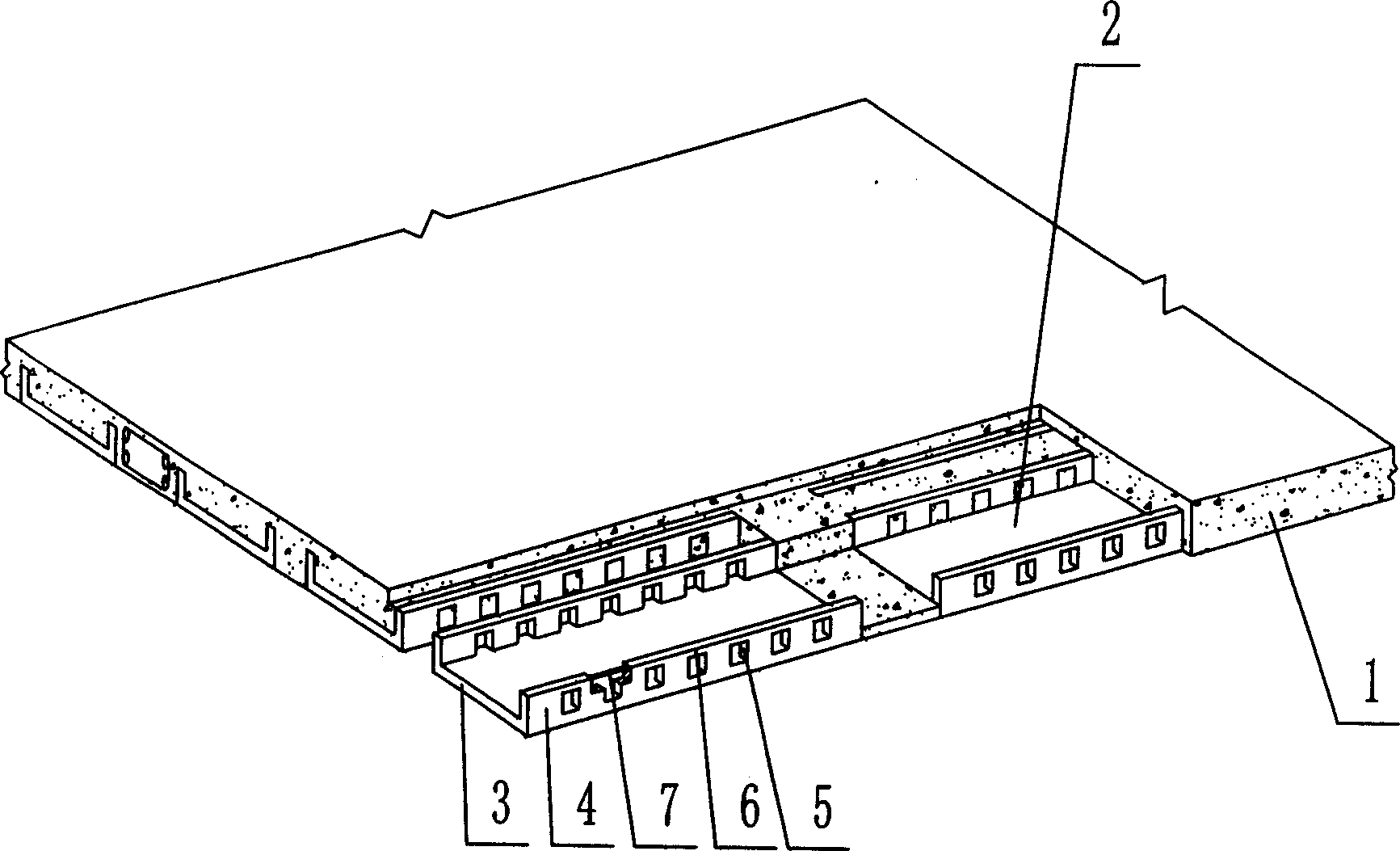

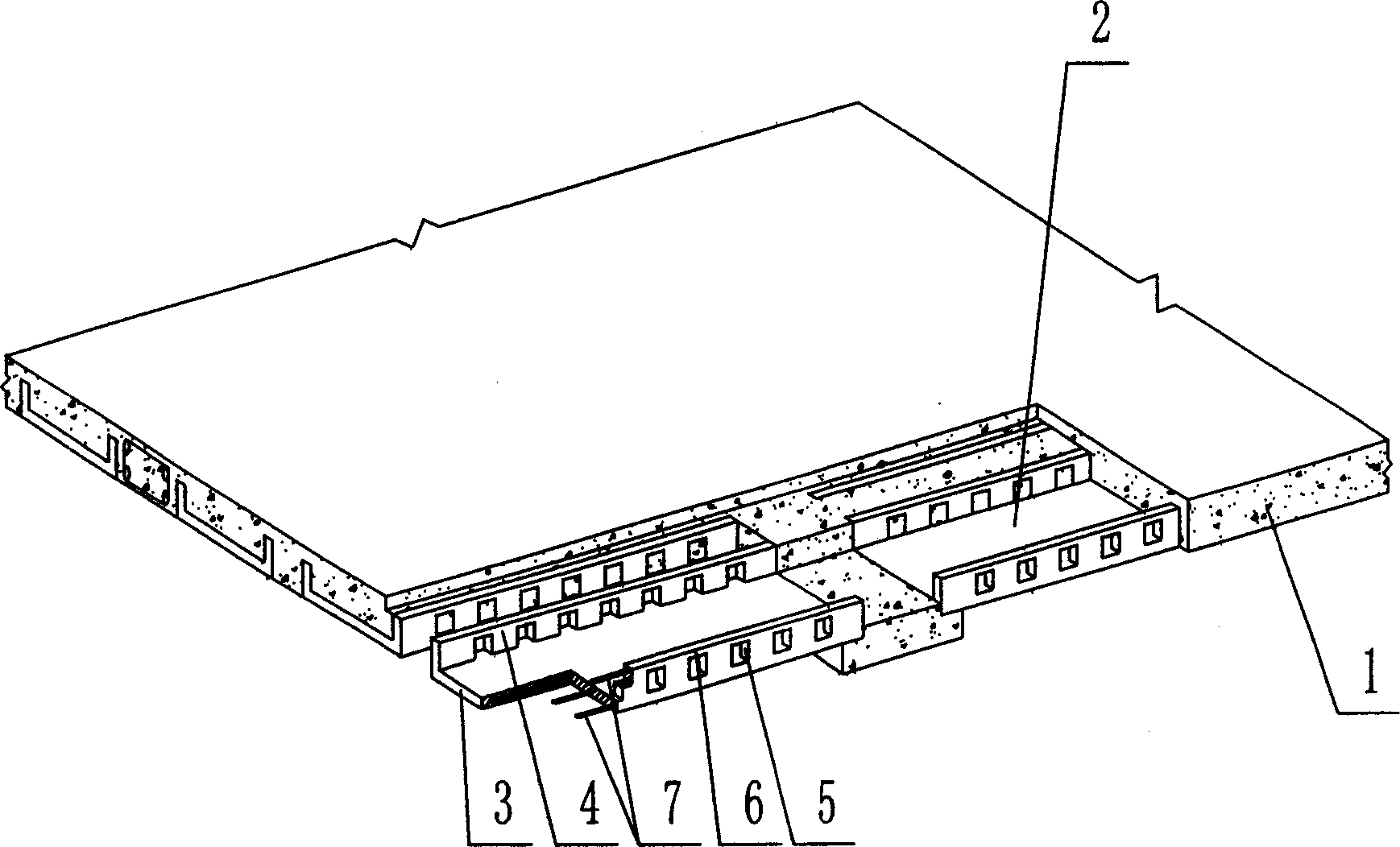

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0049] As shown in the accompanying drawings, the present invention includes reinforced concrete 1, prefabricated components 2, the prefabricated components 2 include a strip-shaped bottom plate 3, and a strip-shaped vertical plate 4, the vertical plate 4 stands on the bottom plate 3, and is connected with the bottom plate 3 to form a whole , a plurality of prefabricated components 2 are assembled with each other, and reinforced concrete 1 is superimposed on them, and they are bonded to each other to form a whole. The plate 4 is orthogonal or oblique to at least one transverse rib cavity 5 for cast-in-place concrete. The top of the transverse rib cavity 5 is a cavity pier 6. The transverse rib cavity 5 on the vertical plate 4 is parallel to each other. The cast-in-place reinforcement Concrete 1 passes through the cavity 5 of the transverse rib. In each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com