Wiredrawing machine for metal material

A metal material and wire drawing machine technology, which is applied in the field of wire drawing machines, can solve the problems of mutual penetration of lubricating oil and drawing liquid, lower precision, and large equipment volume, and achieve good isolation and sealing performance, prolong service life, and reasonable position design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

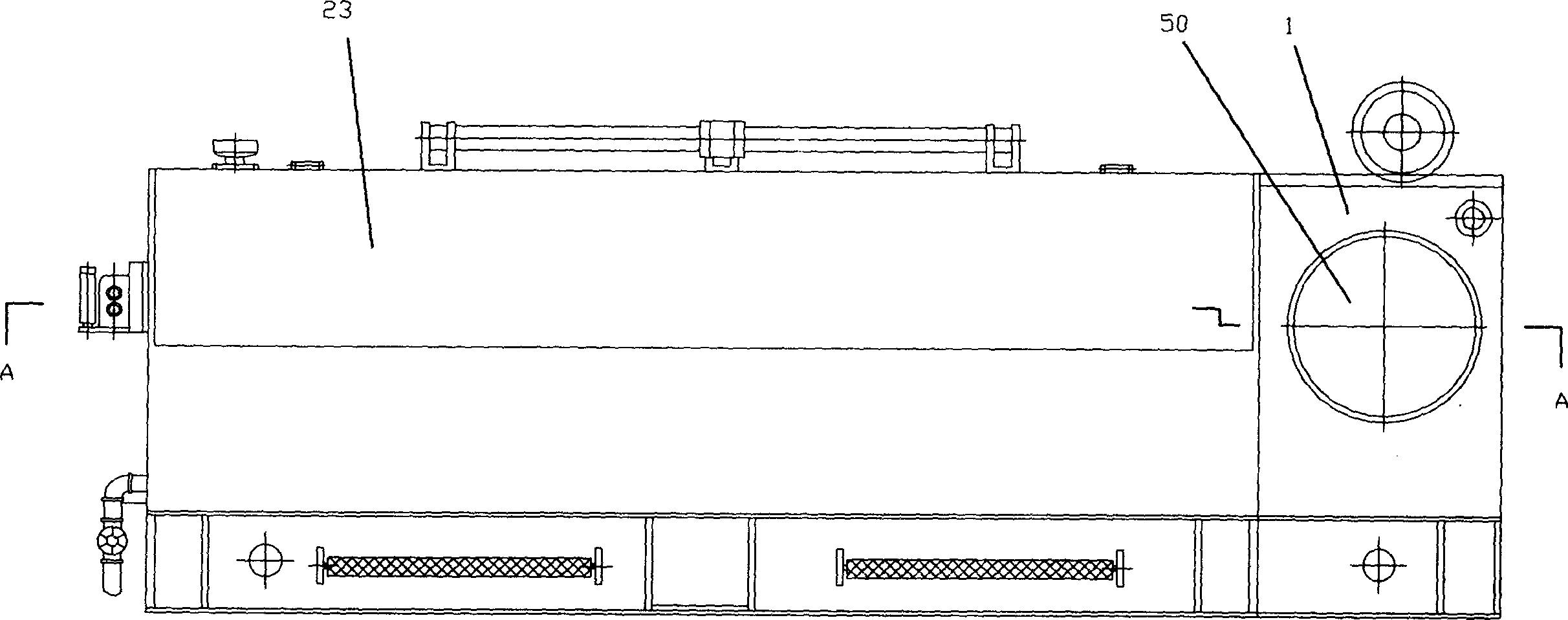

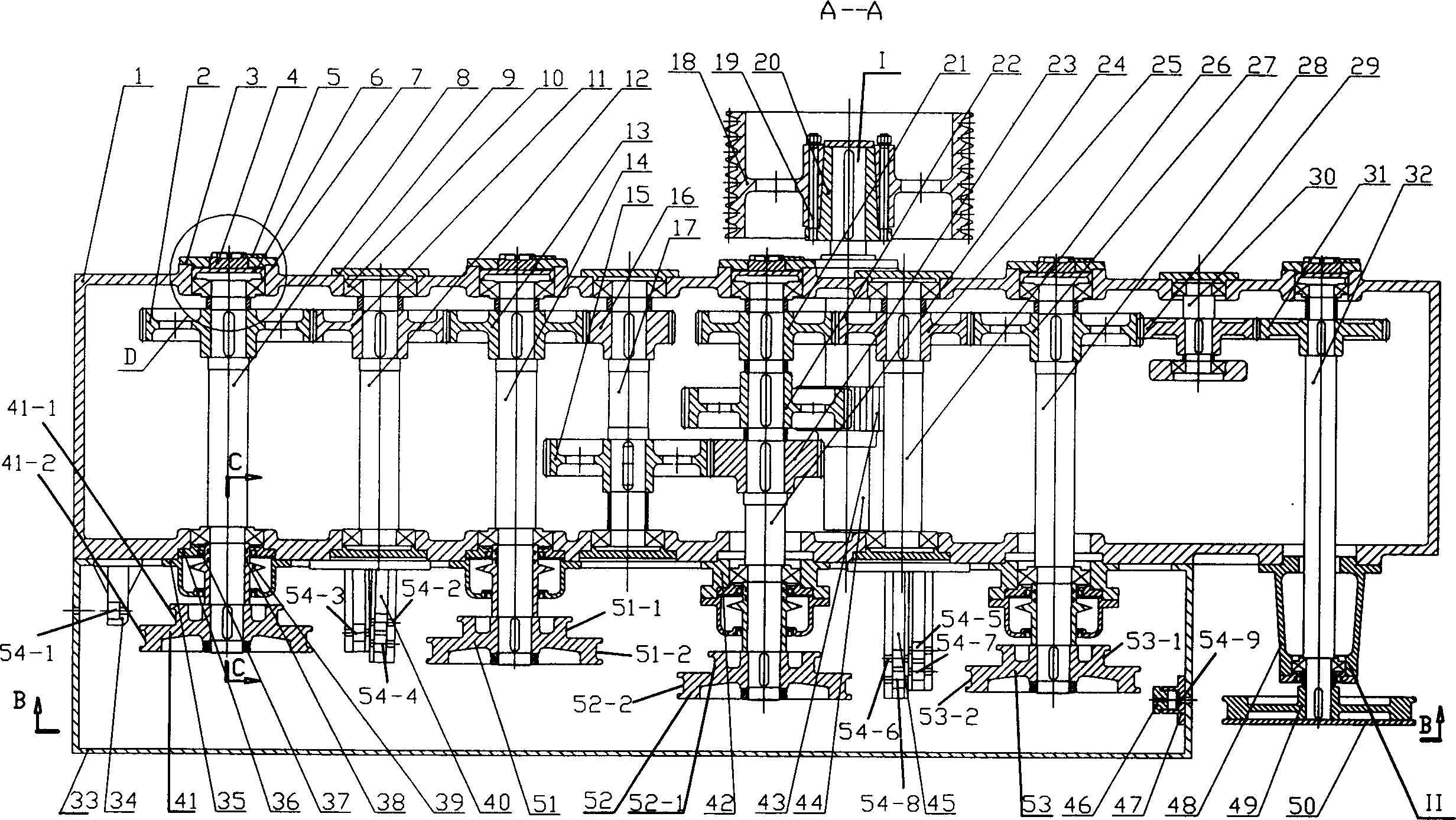

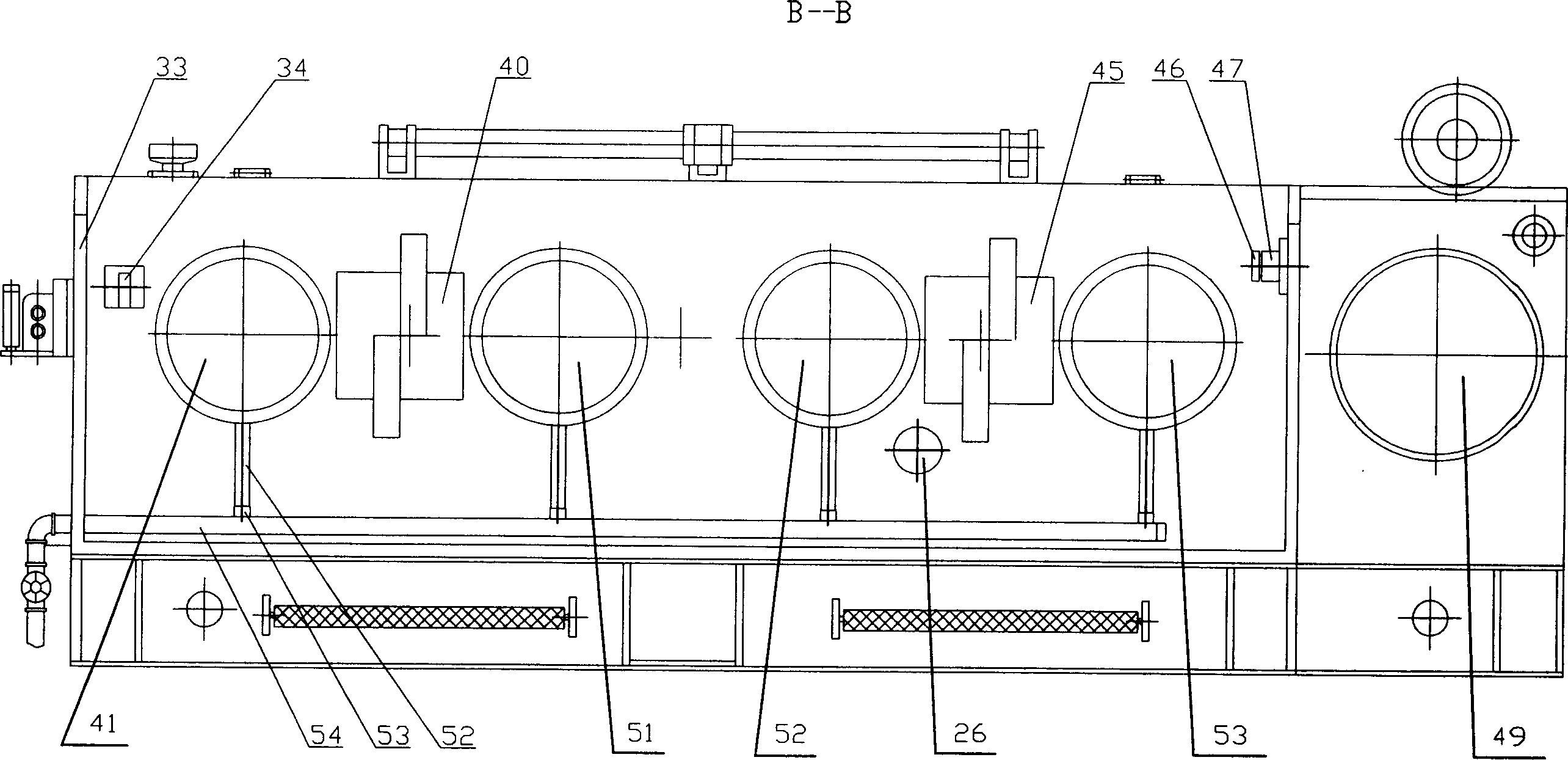

[0019] see Figure 1 ~ Figure 3 , the present embodiment comprises a transmission mechanism I, a wire drawing mechanism II, a gear rotating box body 1 and a water box body 33, and the water box body 33 is fixedly connected to the gear turning box body 1 by bolts. Transmission mechanism 1 is made up of belt pulley 18, adapter sleeve 20, double-ended screw rod 19, input shaft 44 and input gear 43, and input gear 43 and adapter sleeve 20 adopt flat key to be fixedly connected on the input shaft 44, and adapter sleeve 20 is positioned at One end of the input shaft 44 and the pulley 18 are fixedly connected to the adapter sleeve 20 through a double-ended screw 19 .

[0020] The drawing mechanism II includes four tower wheel shafts, four transition shafts and a constant speed wheel shaft, which are respectively the first tower wheel shaft 8, the second tower wheel shaft 14, the third tower wheel shaft 28, the fourth tower wheel shaft 24, and the first transition shaft 12. The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com