Resin composition for encapsulating semiconductor chip and semiconductor device therewith

A resin composition and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid device parts, electric solid devices, etc., can solve the problems that cannot meet the crack resistance, high fluidity and fire resistance at the same time, and achieve curing Sex, the effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

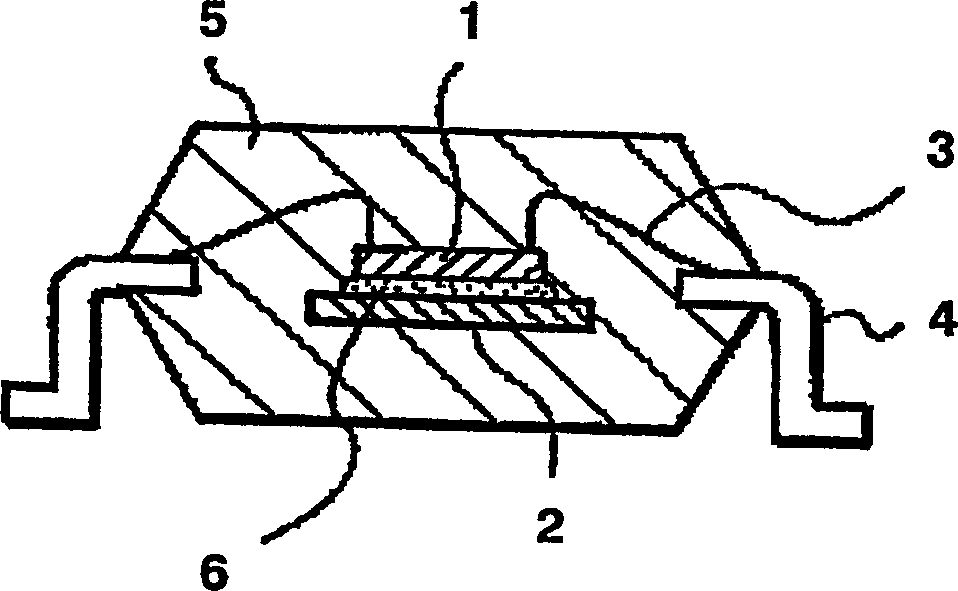

[0084] figure 1 The semiconductor device can be manufactured by casting and curing the above-mentioned epoxy resin composition as the encapsulation resin 5 by suitable methods such as transfer molding, compression molding, and injection molding, and then encapsulating the semiconductor chip 1 .

[0085] because figure 1 The illustrated semiconductor device is encapsulated by an encapsulating resin composition comprising a compound (F) comprising two or more hydroxyl groups bonded to each adjacent carbon atom on an aromatic ring, thereby Appropriate viscosity and flow characteristics of the encapsulating resin composition can be obtained. Therefore, a semiconductor device having good moldability can be stably provided.

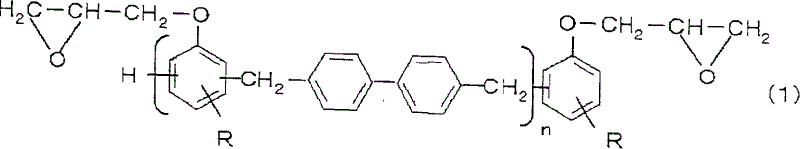

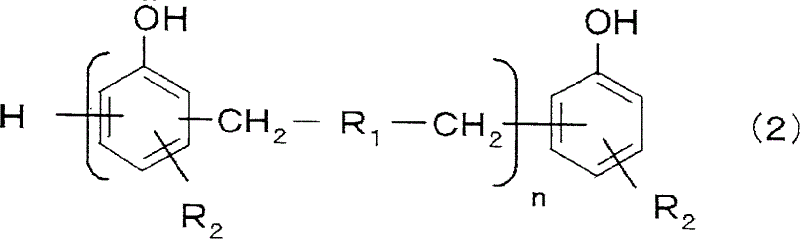

[0086] Use the epoxy resin composition that comprises the epoxy resin of general formula (1) and the phenolic resin of general formula (2) to package semiconductor chip, then can provide the semiconductor with better flame retardancy and soldering resistance ...

Embodiment 1

[0089] Phenol biphenyl aralkyl type epoxy resin (Nippon Kayaku Co., Ltd., NC3000-P, epoxy equivalent: 274, "n" in general formula (1) is 2.8 on average, softening point: 58°C) : 7.35 parts by weight;

[0090] Phenol biphenyl aralkyl resin (Meiwa Kasei Co., Ltd., MEH-7851SS, hydroxyl equivalent: 203, "n" in general formula (2) is 2.5 on average, softening point: 65°C): 5.5 parts by weight ;

[0091] Spherical fused silica (average particle size: 30 μm): 86.0 parts by weight;

[0092] γ-glycidyl propyl-trimethoxysilane: 0.4 parts by weight;

[0093] Triphenylphosphine: 0.2 parts by weight;

[0094] 2,3-dihydroxynaphthalene (reagent grade): 0.05 parts by weight;

[0095] Carnauba wax: 0.2 parts by weight; and

[0096] Carbon black: 0.3 parts by weight

[0097] Mix in a mixer at room temperature, then melt and knead at 80° C. to 100° C. with a hot roller, cool, and then grind to obtain an epoxy resin composition. The obtained epoxy resin composition was measured as follows. ...

Embodiment 2-13 and comparative example 1-15

[0103] According to the mixing ratios shown in Tables 1 and 2, the epoxy resin composition was prepared and determined according to the method described in Example 1. The measurement results are shown in Tables 1 and 2.

[0104] Except the component among the embodiment 1, other components used are as follows:

[0105] Biphenyl type epoxy resin (Japan Epoxy Resin Inc., YX4000H, epoxy equivalent: 195, melting temperature: 105°C);

[0106] Phenol aralkyl resin (Mitsui Chemical Inc., XLC-LL, hydroxyl equivalent: 174, "n" in general formula (2) is 3.6 on average, softening point: 79° C.);

[0107] Cresol novolac epoxy resin (Nippon Kayaku Co., Ltd., EOCN 1020-55, epoxy equivalent: 198, softening point: 55°C);

[0108] Phenol phenolic resin (hydroxyl equivalent: 104, softening point: 80°C);

[0109] γ-Mercaptopropyltrimethoxysilane;

[0110] 1,8-diazabicyclo(5,4,0)undecene-7 (hereinafter referred to as "DBU");

[0111] A curing accelerator represented by general formula (7); ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com