Method and installation for two-step type prodn. of melamine

A melamine and equipment technology, applied in the two-step process and equipment field of melamine, can solve the problems of large consumption of ammonia gas, large energy consumption, long process flow, etc., and achieve reduction in equipment repair and maintenance, reduction in operating points, and production The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

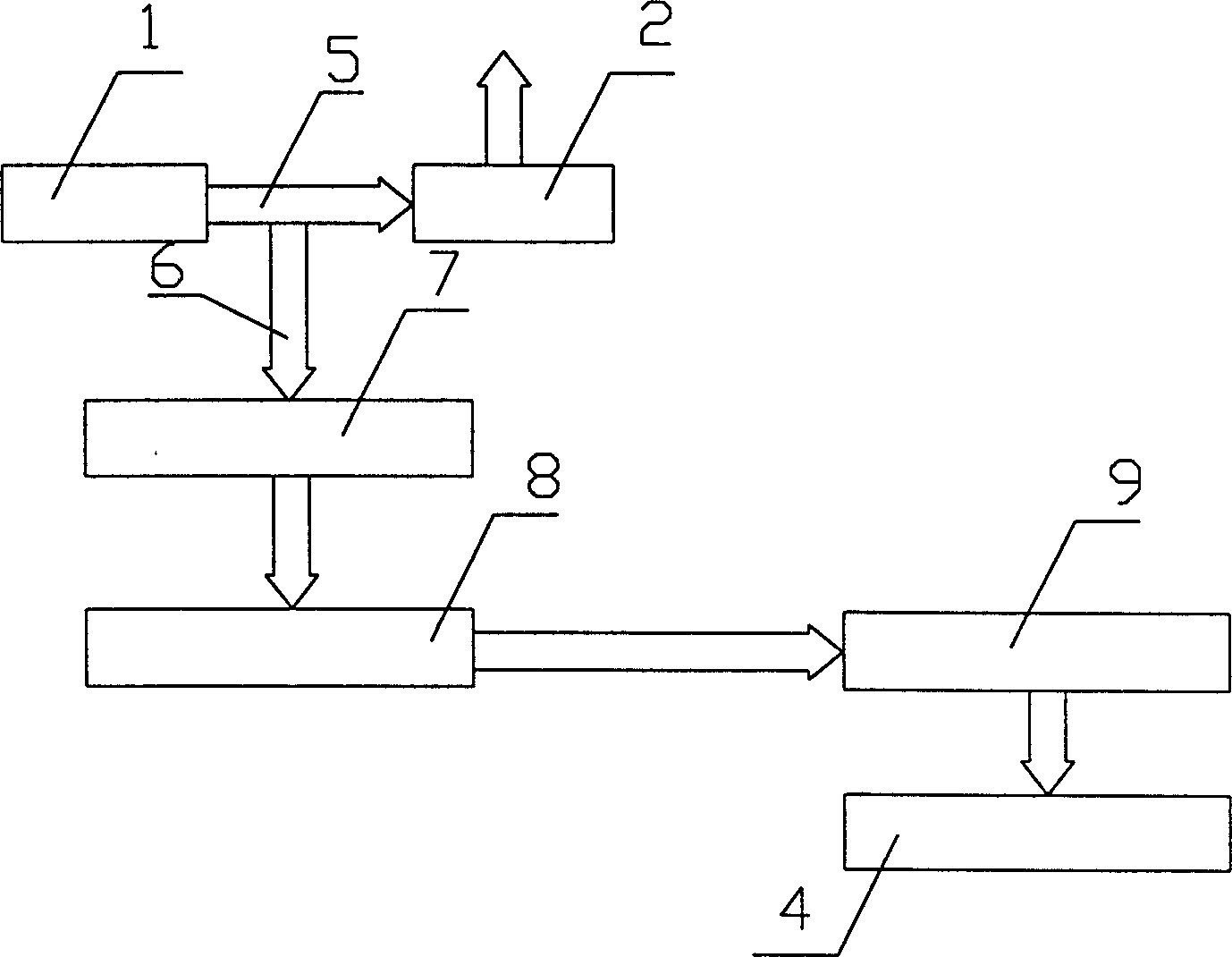

[0011] Such as figure 2 In comparison, the equipment for producing melamine by the two-step method of the present invention comprises a reactor 4, a catcher 1, and an absorption tower 2, and the gas outlet of the catcher 1 is equipped with two gas paths 5,6 to communicate with the absorption tower 2 and the absorber 2 respectively. A reactor 4, wherein a cooler 7, a filter 8, and a hot press 9 are sequentially arranged on the gas path 6.

[0012] The equipment adopting the above structure can have the following working process: the tail gas (the mixture containing ammonia, carbon dioxide and a small amount of melamine low-temperature by-product) from the trap 1 is divided into two paths by the gas path 5 and 6, which are respectively directed to the absorption tower 2 and the reaction 4, the tail gas entering the absorption tower 2 through the gas path 5 enters the absorption tower 2 for washing and absorption, it first absorbs the carbon dioxide in the gas from the concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com