Equalizing synthetic insulator

A synthetic insulator, voltage-equalizing technology, applied in insulators, suspension/strain insulators, electrical components, etc., can solve the problems of shortened life of synthetic insulators, uneven distribution of electric field strength, and electrical erosion of outer sheaths. Accident, small investment, quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

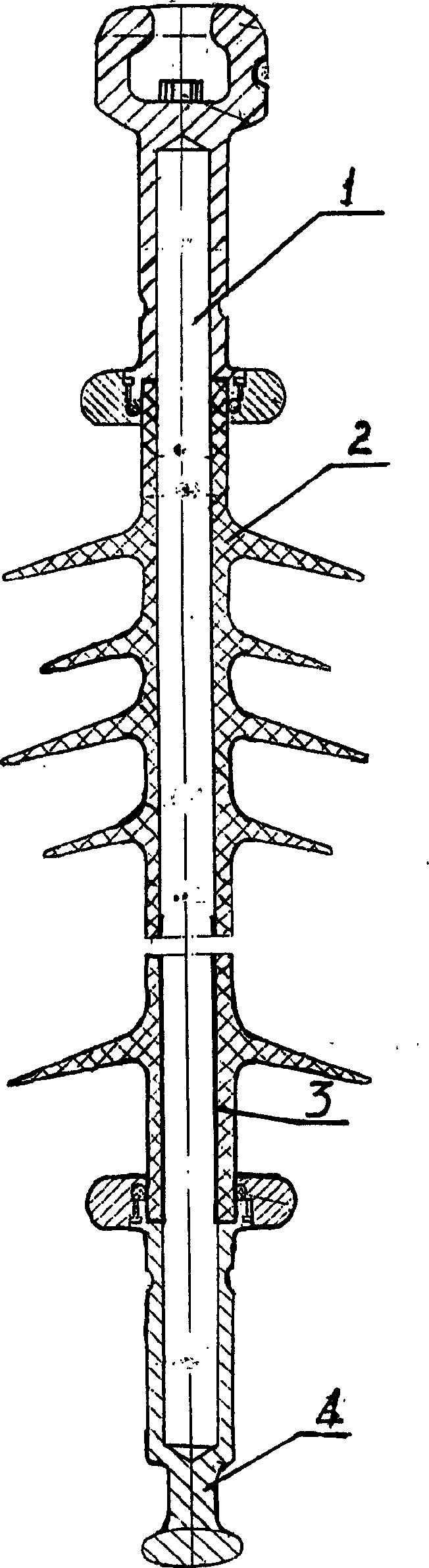

[0008] As shown in the accompanying drawings, the present invention includes an insulator. There is a semiconductor material layer 3 between the mandrel 1 and the outer sheath 2 of the insulator near the live end, and the semiconductor material layer 3 is electrically connected to the gold fitting 4 at the live end. The thickness of the semiconductor material layer 3 is 0.1-4mm, and the length is 50-1000mm. There is no gap between the semiconductor material layer 3 and the core rod 1 and the outer sheath material 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com