Angle reference laser digital sensor

A technology of digital sensors and lasers, applied in the direction of instruments, measuring instruments, measuring inclination, etc., can solve the problems of large zero reference error, lower design hit rate, and inability to provide digital signal control system, etc., and achieve simple and reliable structure and shock resistance superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

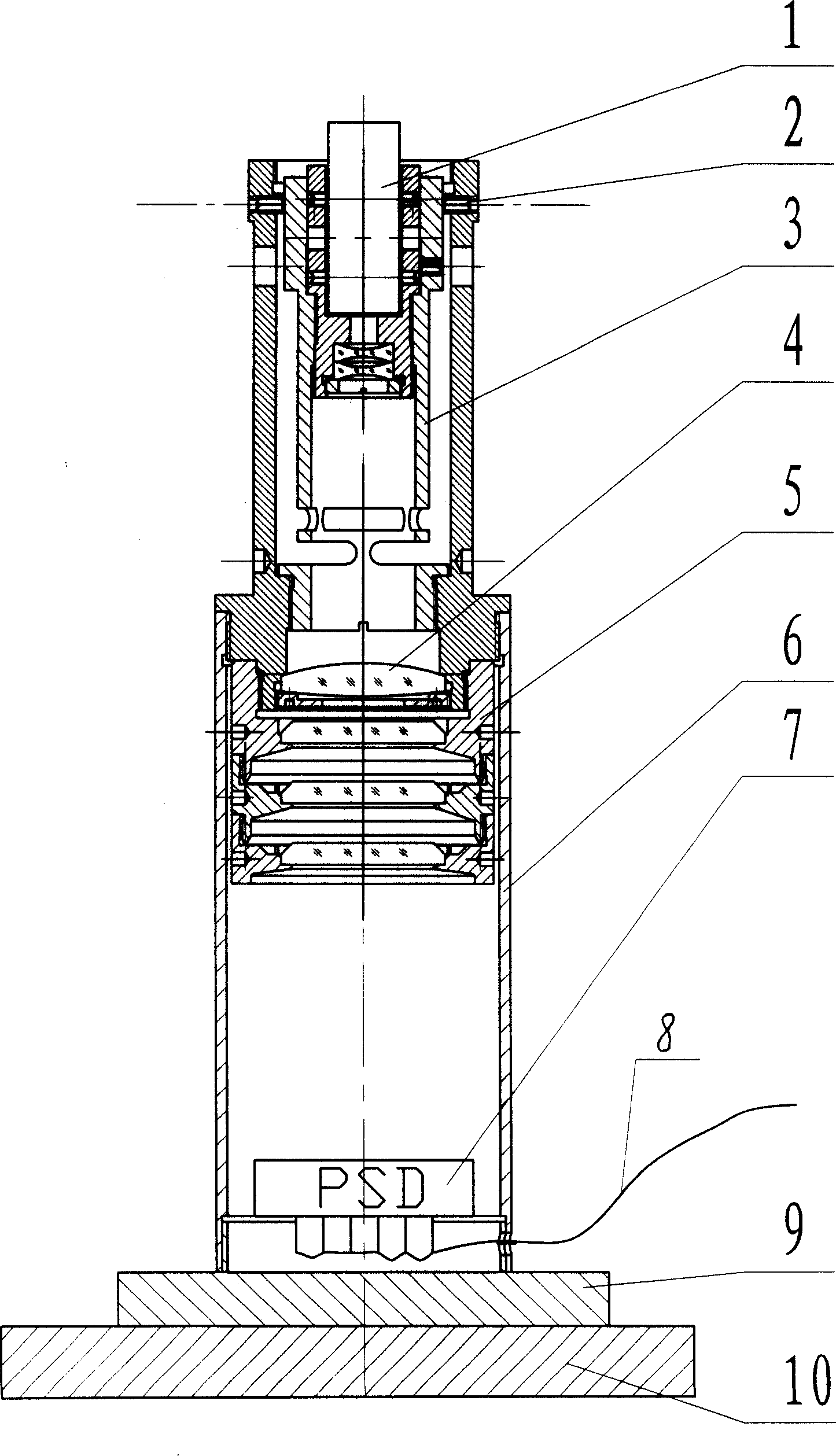

[0011] For the angle reference laser digital sensor shown in the figure, the semiconductor laser 1 with a wavelength of 635 or 650nm is installed on the adjustment universal joint 3, and the adjustment universal joint is installed on the top of the housing 6, and the adjustment universal joint and the laser adjustment nail 2 can be adjusted The position of the laser, the spot modulation optical system 4 and the liquid double wedge compensator 5 are sequentially fixed inside the housing from top to bottom, the PSD position photoelectric sensor 7 is fixed on the base 9 at the bottom of the housing, and the signal output line 8 is connected to the outside of the housing. The light spot modulation optical system is a set of lenses that can modulate the light spot into a light spot with a diameter of less than 2mm, preferably a lens that can modulate the light spot into a light spot with a diameter of less than 1mm. Two airtight containers are formed, transparent compensating liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com