Prepn process of mixable silicon rubber structure controlling agent

A technology of silicone rubber and structurant, applied in the field of preparation of kneading silicone rubber anti-structural agent, can solve the problems of high yield of volatile components, cumbersome and energy-consuming post-processing, difficult solvent recovery, etc., and achieve excellent anti-structural agent. performance, improved tear strength, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

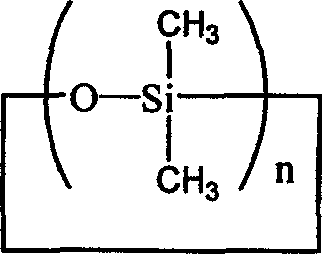

[0027] The preparation of embodiment 1 mixing type silicone rubber anti-structural agent

[0028] Take 300g D 4 First carry out vacuum distillation to remove 15g of cyclic body and water, then add 60g of dimethyldimethoxysilane, stir evenly, heat up to 80°C, add 15g of granular activated clay (80 mesh), stir for 1 hour at constant temperature, and then slowly Slowly raise the temperature to 100°C and continue to stir and heat-retain for 3 hours, then cool down to 80°C, add 18g of water and heat-retain for 3 hours at 64°C, cool to room temperature, filter to remove activated clay, and distill the filtrate under reduced pressure to remove 30g of low-molecular substances, and finally obtain 310g Colorless, transparent liquid, the yield is 85%, and its viscosity is 11.5mm 2 / s, the hydroxyl content is 6.62% (mass percentage, the same below), and the methoxy content is 4.27%.

Embodiment 2

[0029] The preparation of embodiment 2 mixing type silicone rubber anti-structural agent

[0030] Take 300g D 4First carry out vacuum distillation to remove 15g of ring body and water, then add 58g of dimethyldiethoxysilane, stir evenly, then raise the temperature to 100°C, add 18g of cation exchange resin, stir and react at constant temperature for 1.5 hours, and then slowly raise the temperature to 110°C Continue to stir and keep warm for 3 hours at ℃, cool down to 90 ℃, add 21g of water at 78 ℃ and keep warm for 3 hours, cool to normal temperature, filter and remove activated clay, and obtain 340g of colorless, transparent liquid with a yield of 93% and a viscosity of 18.0 mm 2 / s, the hydroxyl content is 6.02%, and the ethoxy content is 3.86%.

Embodiment 3

[0031] Embodiment 3 Preparation of mixing type silicone rubber anti-structural agent

[0032] Take 300g of DMC and first carry out vacuum distillation to remove 15g of DMC and water, then add 60g of dimethyldimethoxysilane, stir evenly, heat up to 80°C, add 21g of activated clay (60 mesh), stir and react at constant temperature for 1 hour, and then Slowly raise the temperature to 100°C and continue to stir and keep warm for 3 hours, then cool down to 70°C, add 18g of water at 64°C and keep warm for 3 hours, then cool to normal temperature, filter to remove activated clay, and distill the filtrate under reduced pressure at 150°C (-0.1Mpa) Slough off 25g low-molecular matter, finally obtain 321g colorless, transparent liquid, yield 88%, and its viscosity is 13.5mm 2 / s, the hydroxyl content is 6.24% (mass percentage, the same below), and the methoxy content is 4.08%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com