Chemical method for preparing film of poly pyrrole in high conductivity on surface of insulating material

A technology of insulating materials and high conductivity, applied in chemical instruments and methods, insulators, chemical/physical processes, etc., can solve problems such as the influence of dopant conductivity that are rarely studied, and achieve reduced energy level difference and easy conduction , the effect of increasing the degree of conjugation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A bisphenol A epoxy resin with an area of 1.1×1.1 cm was immersed in a solution of γ-chloropropyltrimethoxysilanol with a mass fraction of 0.5%, and the surface was modified at a temperature of 20°C. After drying, immerse in the 30% pyrrole monomer solution at a temperature of 20°C for 3 minutes, then immerse in the 20% oxidant iron trichloride solution for 5 minutes, then use deionized water and no Wash with water and ethanol, and dry at room temperature; repeat the operation of immersing the epoxy resin in the pyrrole monomer solution and the oxidant aqueous solution for 2 times, and react in the ferric chloride solution for 30 minutes in the last pass, and then use deionized water and anhydrous water respectively. After washing with ethanol and drying the sample at 25°C, a polypyrrole film attached to the surface of the bisphenol A epoxy resin was obtained, with an electrical conductivity of 5-10 S / cm.

Embodiment 2

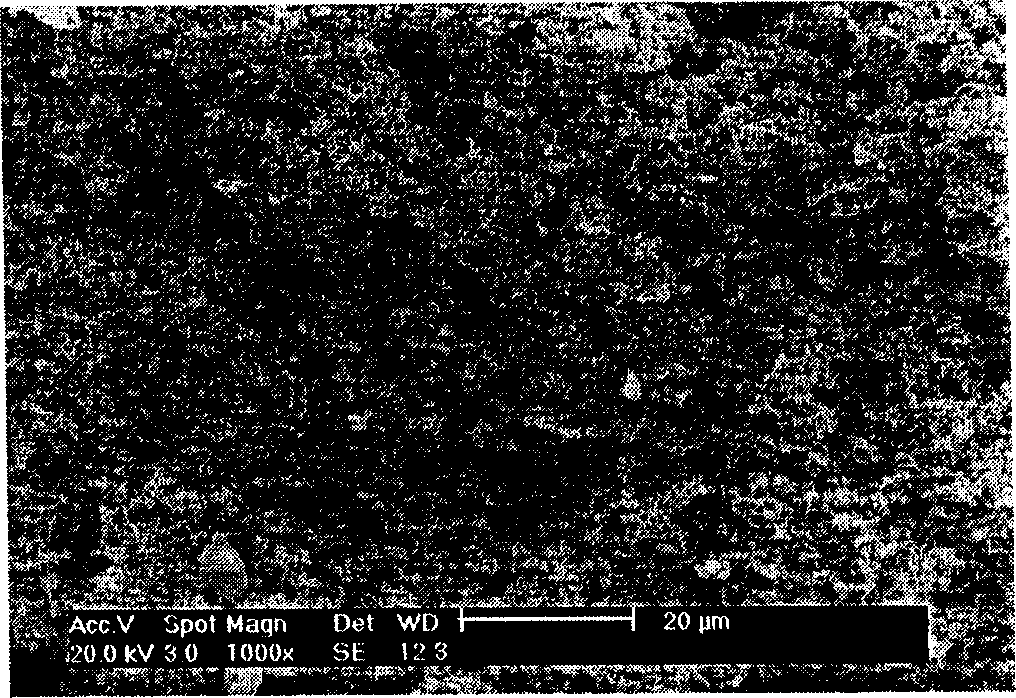

[0018] This example is similar to Example 1, except that the dopant sodium p-toluenesulfonate is added to the oxidizing agent solution, and the electrical conductivity of the polypyrrole film obtained by using different doping amounts is shown in Table 1. It can be seen that , with the increase of doping amount, the electrical conductivity of the polypyrrole film shows a trend of increasing slowly. When it increases to a certain value, the electrical conductivity reaches the highest value. If the doping amount continues to increase, the electrical conductivity of the polypyrrole film tends to decrease again. , so less or too much doping can not get the ideal conductivity. The optimal doping amount is 4.2g / 100mL, and the surface morphology of the prepared conductive polypyrrole film is as follows: figure 2 shown.

[0019] p-toluenesulfonate

Embodiment 3

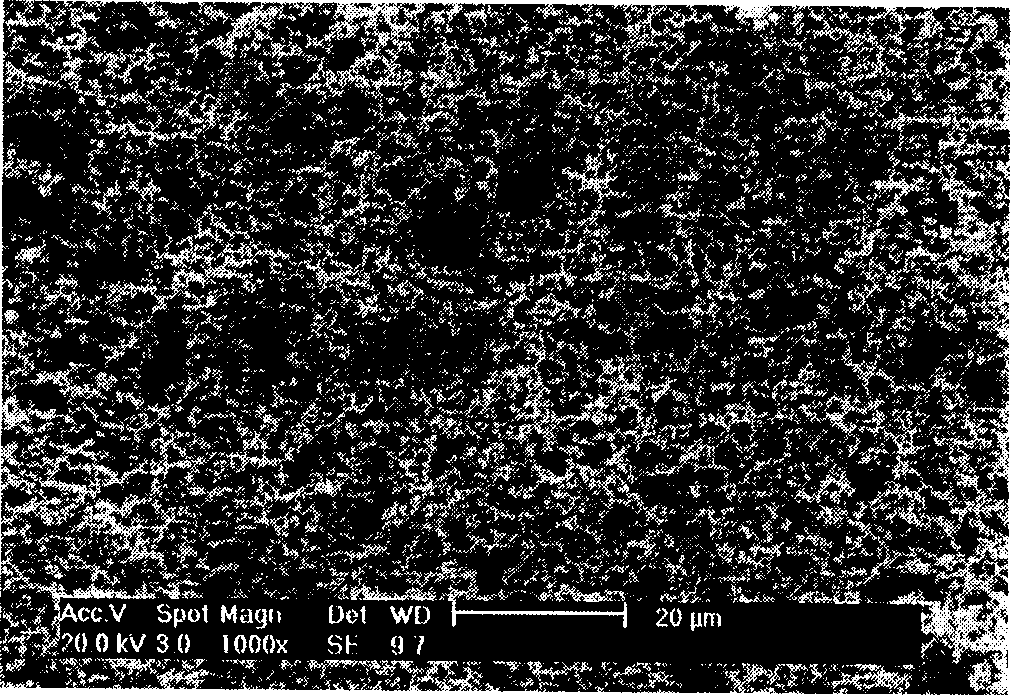

[0021] This example is similar to Example 1, except that the dopant added to the oxidant solution is sodium dodecylbenzenesulfonate. The electrical conductivity of the polypyrrole film obtained by using different doping amounts is shown in Table 2. It can be seen that the electrical conductivity obtained by doping sodium dodecylbenzenesulfonate is relatively high, and the optimal doping amount is 3.3g / 100mL , the surface morphology of the prepared conductive polypyrrole film is as follows image 3 shown.

[0022] dodecylbenzenesulfonate

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com