Oscillating arm type automatic switching apparatus of tray for work pieces

An automatic exchange, swing arm technology, applied in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., to achieve the effect of correct and reliable exchange position and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

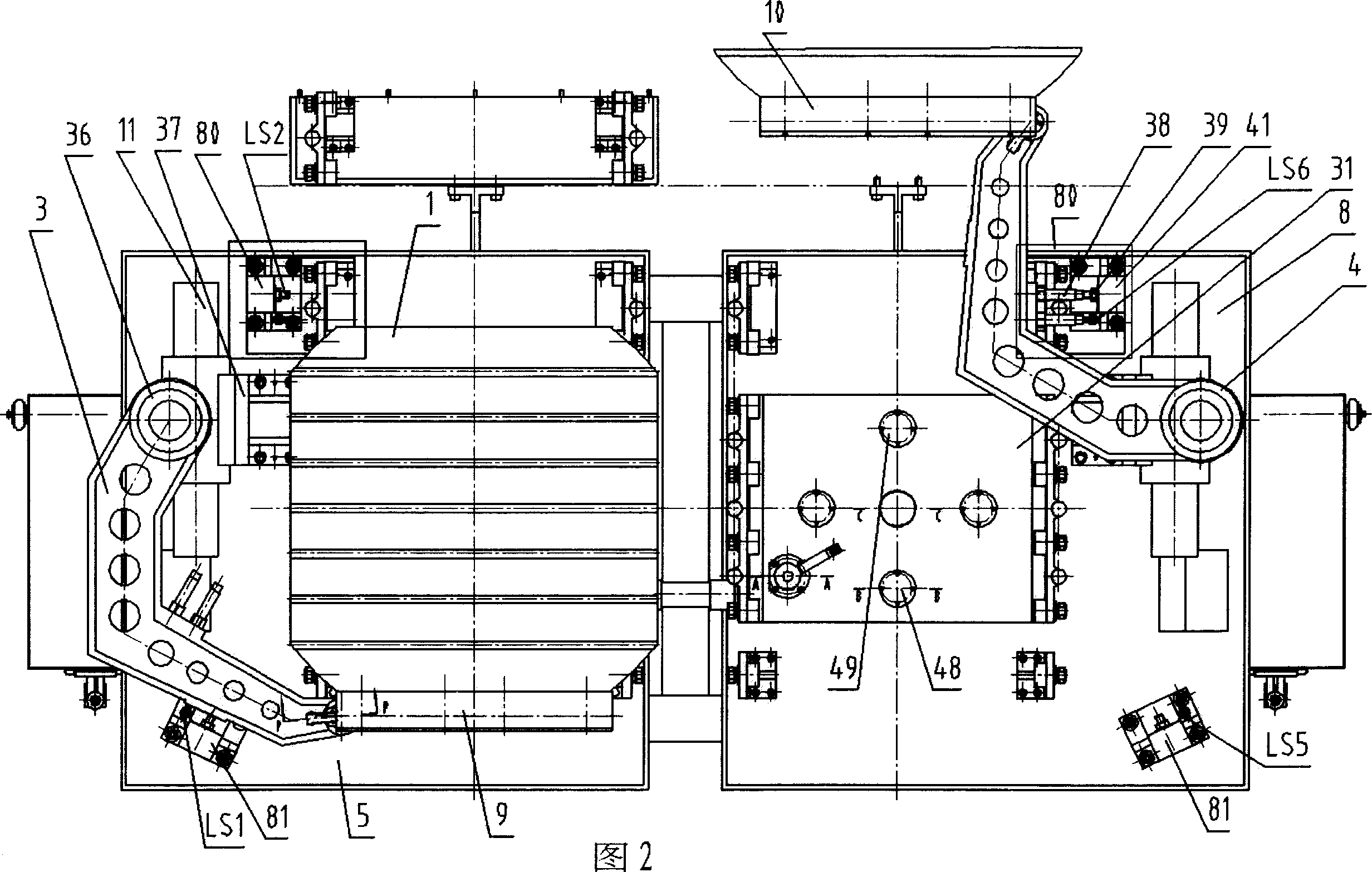

[0032] As shown in Figures 1, 2, 3, 6, and 7, the swing arm type workpiece pallet automatic exchange device consists of exchange pallet bases 5, 8 installed in front of the bed, left and right sides, and left and right supports on the bases 5, 8. Two worktables 1, 2 on the board track, a rotary table 53 below the worktable, a hydraulic transmission system, a pneumatic control system, a PLC electrical control system, an operation panel and the like.

[0033] The length and width of the two workbenches 1 and 2 are both 800mm. Turntables 30 and 31 are arranged under the workbenches 1 and 2 and above the base. Shallow positioning sleeves 49, deep positioning sleeves 48 and signaling switches are installed on the rotating disks 30 and 31. Between the rotating disks 30 and 31 and the bases 5 and 8, a Slewing mechanism 70, turntable 30, 31 pallets below are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com