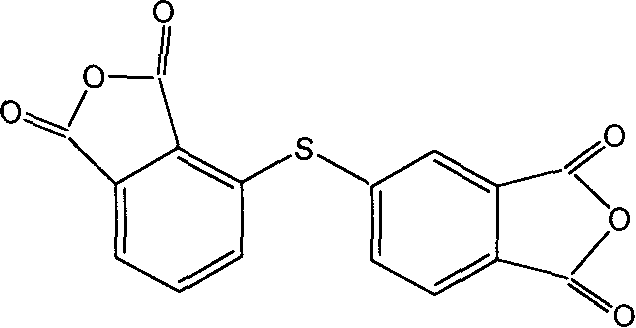

Preparation methd of 2,2',3,4'-diphenyl thioether tetra acid dianhydride

A technology of diphenyl sulfide and tetraacid dianhydride, which is applied in 2 fields, can solve the problems of difficult complete dehydration of vulcanizing agents, low yield, and difficult separation, etc., and achieves improved yield, reduced production cost, and simple synthesis process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

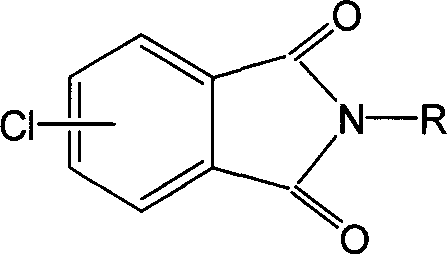

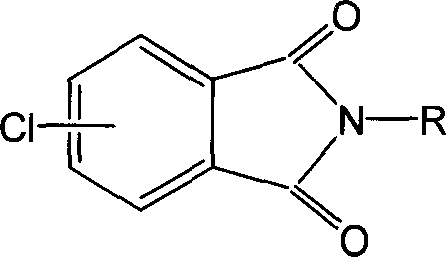

[0025] (1) In a dry 500 ml round bottom flask, add 39.12 grams (0.2mol) of N-methyl-4-chlorophthalimide, 14.63 grams (0.106mol) of anhydrous potassium carbonate, 17.46 grams The mass percentage content is 68-72% sodium hydrosulfide and 120 grams of dimethyl sulfoxide, feed nitrogen to remove the air in the bottle, stir mechanically, heat up to 130 ° C for 2 hours, cool to room temperature, and slowly Pour into 400 ml of 20% dilute hydrochloric acid, collect the solid, then dissolve the crude product in 650 ml of 5% potassium carbonate solution, filter to remove insoluble matter, acidify the filtrate to PH=1 with dilute hydrochloric acid, and precipitate white Precipitate, filter, wash the filter cake three times with distilled water, and dry under vacuum at 80°C to obtain 35.53 grams of N-methyl-4-mercapto substituted phthalimide, with a yield of 92% (based on N-methyl-4-chloro Phthalimide calculation), the melting point of 136-138 ° C.

[0026] (2) Add 19.31 (0.1mol) gram N-...

Embodiment 2

[0029] (1) Add 51.54 grams (0.2mol) of N-phenyl-4-chlorophthalimide, 14.63 grams (0.106mol) of anhydrous potassium carbonate, 17.46 grams in a dry 500 milliliter round bottom flask The mass percentage content is 68-72% sodium hydrosulfide and 170 grams of dimethyl sulfoxide, feed nitrogen to remove the air in the bottle, mechanically stir, heat up to 150 ° C for 2 hours, after cooling to room temperature, slowly Pour into 1000 ml of 20% dilute hydrochloric acid, collect the solid, then dissolve the crude product in 1000 ml of 3% potassium carbonate solution, filter to remove insoluble matter, acidify the filtrate to PH=2 with dilute hydrochloric acid, and precipitate white Precipitate, filter, wash the filter cake three times with distilled water, and dry under vacuum at 80°C to obtain 46.45 grams of N-phenyl-4-mercapto substituted phthalimide, with a yield of 91% (based on N-phenyl-4-chloro phthalimide calculation).

[0030] (2) Add 25.52 (0.1mol) gram N-phenyl-4-mercapto su...

Embodiment 3

[0033] (1) Add 39.12 grams (0.2mol) of N-methyl-3-chlorophthalimide 13.81 grams (0.10mol) of anhydrous potassium carbonate in a dry 500 milliliter round bottom flask, 17.46 grams of quality The percentage content is 68-72% sodium hydrosulfide and 250 grams of dimethylformamide, pass nitrogen gas to remove the air in the bottle, stir mechanically, heat up to 150 ° C for 0.5 hours, after cooling to room temperature, pour it slowly into 400 milliliters of 10% dilute hydrochloric acid, collect the solid, then dissolve the crude product in 500 milliliters of 20% potassium carbonate solution, filter to remove the insolubles, and acidify the filtrate to PH=3 with dilute hydrochloric acid, and precipitate a white precipitate , filtered, the filter cake was washed three times with distilled water, and vacuum-dried at 80°C to obtain 33.99 grams of N-methyl-3-mercapto substituted phthalimide, with a yield of 88% (using N-methyl-3-chloro-ortho phthalimide calculation).

[0034] (2) Add 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com