Hot pressing process for steel sheet rolling wheel

A hot pressing process and roller technology, applied in the field of metal parts pressure processing, can solve the problems of reduced accuracy and strength of the roller, uneven wall thickness of the roller, and failure to meet the standard requirements, reducing welding deformation and stress, and low cost. , The effect of improving product accuracy and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

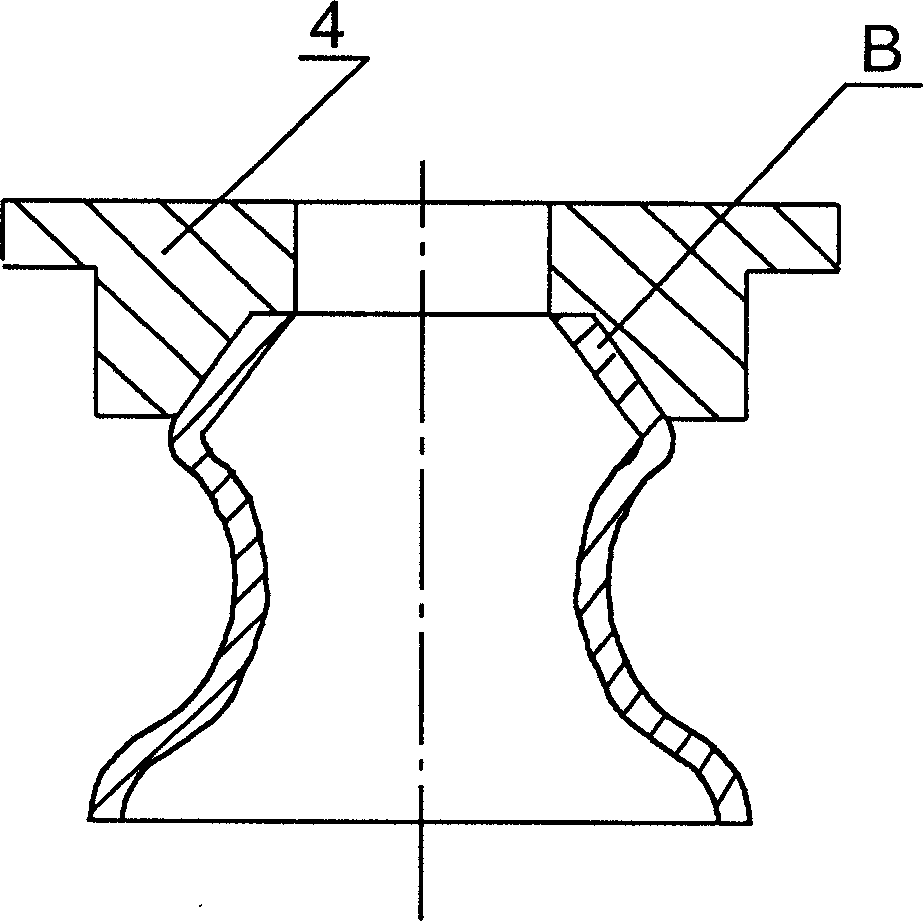

[0016] Referring to the attached drawings, after the steel plate is unloaded, it is rolled into a cylindrical shape, welded into a steel pipe, and becomes a roller blank 1 ( figure 1 ). First, heat the A-end of the billet locally to 860°C in a salt bath furnace, and then hot-press it into a trumpet shape through the flaring die 2 on the press (Fig. 2); then locally heat the B-end of the billet to 860°C in the salt bath furnace. ℃, hot-pressed into a trumpet shape through the flaring die 2 on the press (Fig. 3), then heated the B end to 860 ℃, and hot-pressed into a drum shape through the shrinking die 4 on the press (Fig. 3). Figure 4 ), and then processed through the forming die 5 within 3 minutes ( Figure 5 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com