Kitchen refuse processing apparatus

A kitchen waste and treatment device technology, applied in the field of kitchen waste treatment devices, can solve problems such as damage to a spray pipe of a treatment tank, and achieve the effects of easy replacement, prevention of damage, and reduction in usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

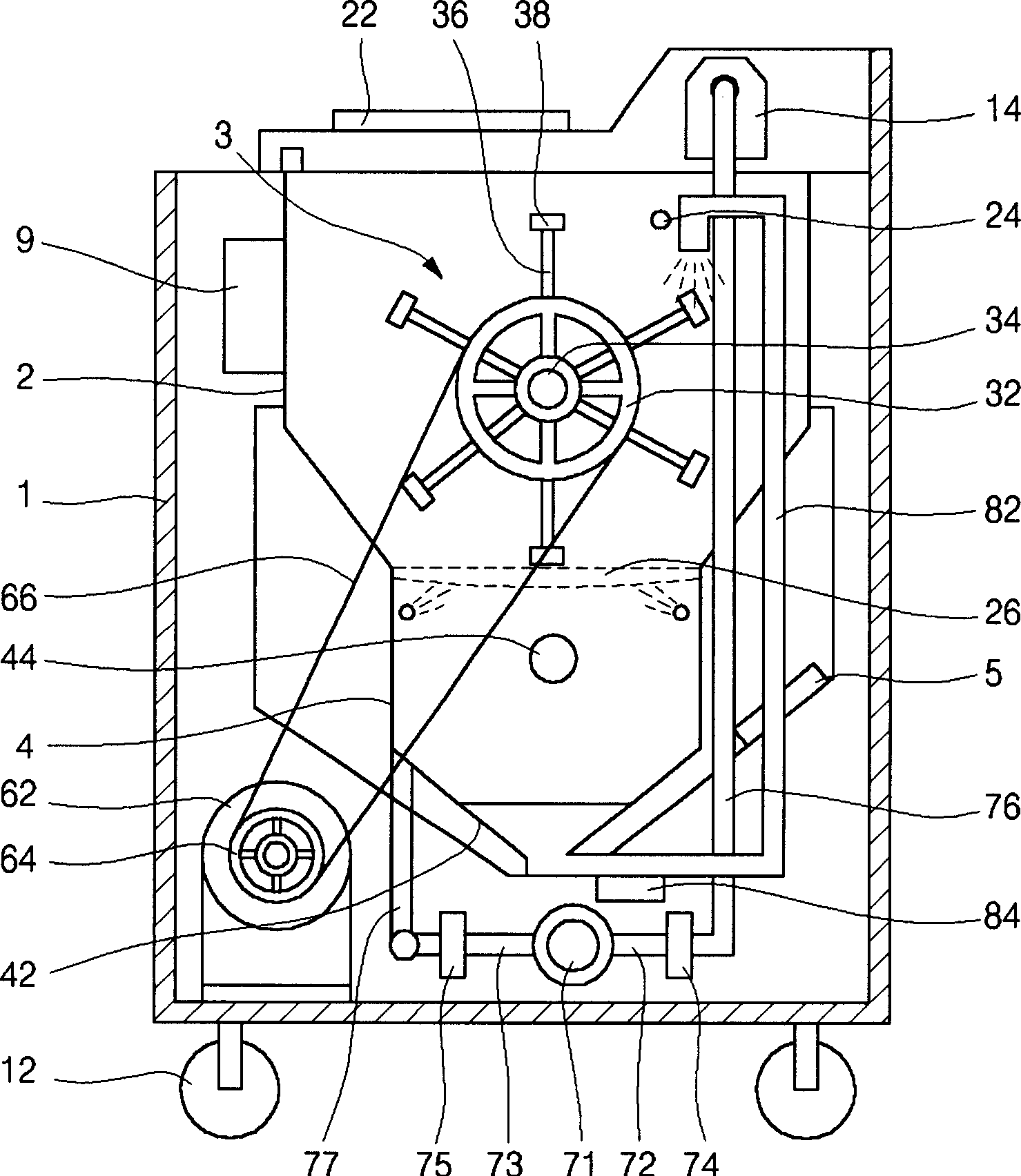

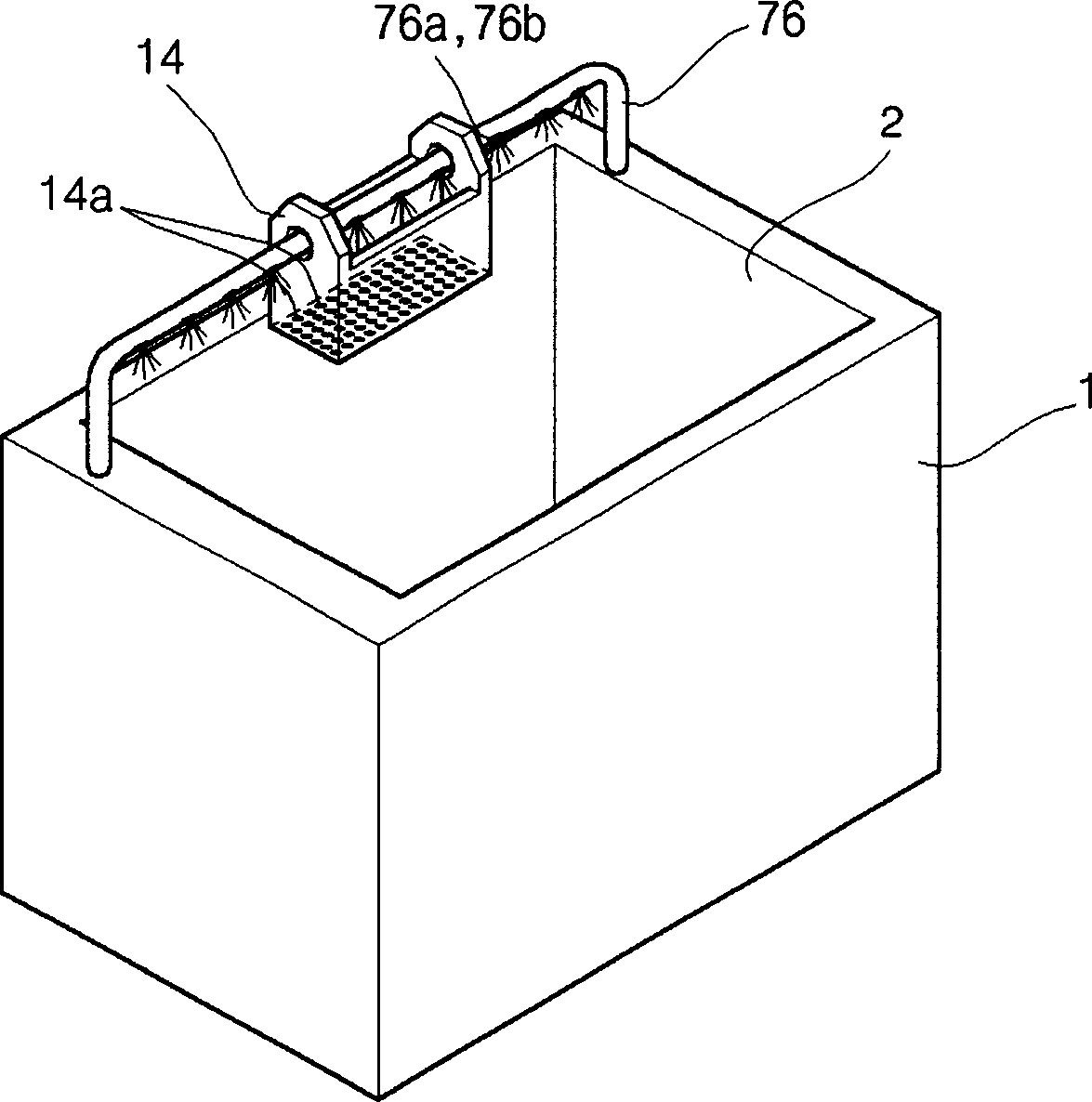

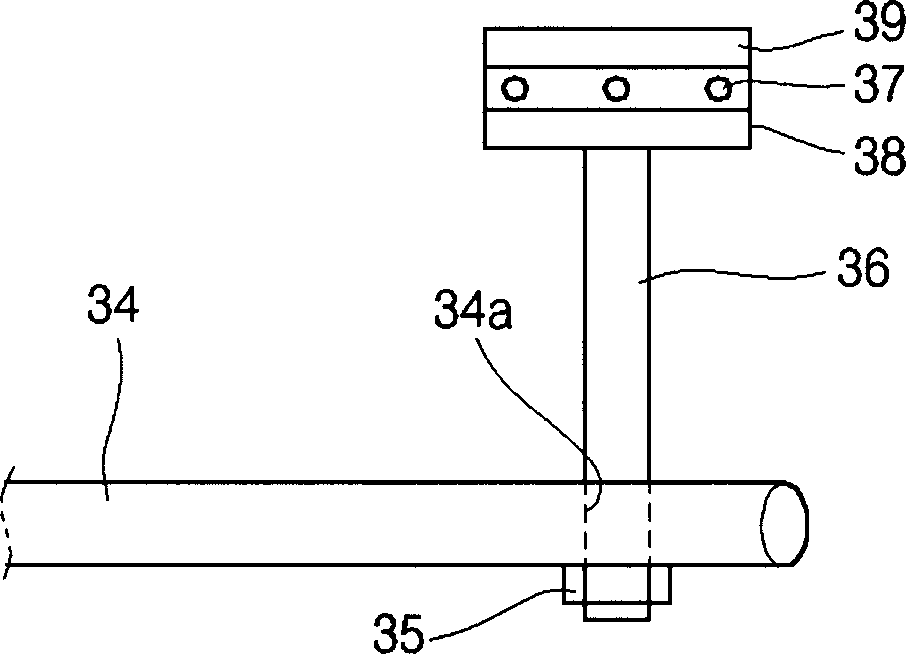

[0035] figure 1 It is a cross-sectional view showing a kitchen waste treatment device according to an embodiment of the present invention, and includes a treatment tank 2, a mixer 3, a drainage tank 4, a heating mechanism 5, a control panel 9 serving as a stirring mechanism, a drainage mechanism, a water resupply mechanism, and a control mechanism etc. are provided inside the casing 1 having a predetermined shape.

[0036] A plurality of rotatable casters 12 are provided on the bottom surface of the housing 1 .

[0037] The above-mentioned treatment tank 2 is arranged at the upper end of the inside of the housing 1 , a mixer 3 is arranged inside the above-mentioned treatment tank 2 , and a drainage tank 4 is provided in communication with the bottom of the treatment tank 2 .

[0038] An openable and closable cover 22 is provided on the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com