Method and system of preparing ITO film using medium frequency reaction magnetic controlled sputtering indium tin alloy target

A reactive magnetron sputtering, indium tin alloy technology, applied in sputtering plating, metal material coating process, ion implantation plating, etc. The effect of material utilization rate, production cost reduction and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

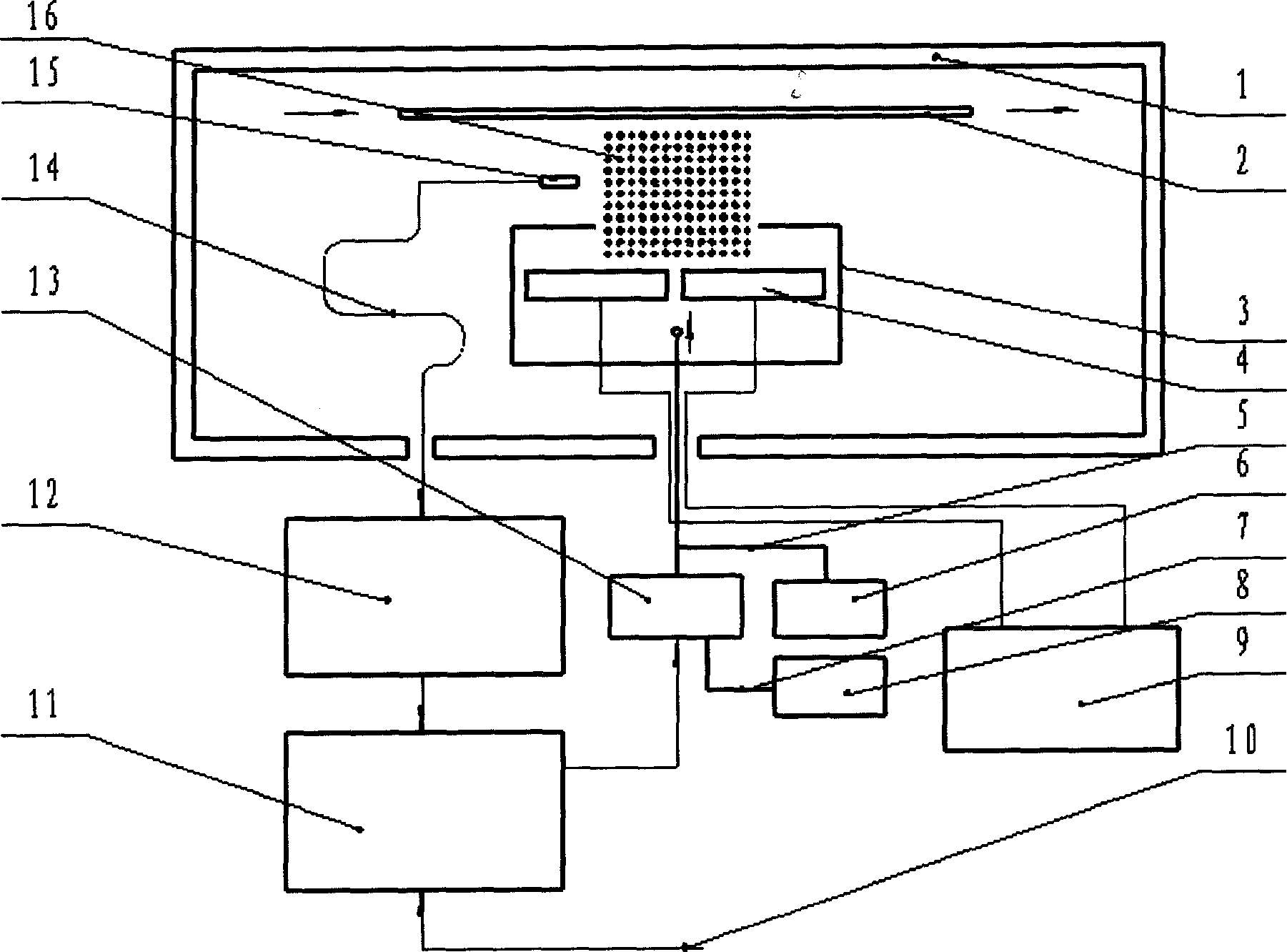

[0020] Attached below figure 1 The present invention is described in further detail:

[0021] A method for preparing an ITO film by using an intermediate frequency reactive magnetron sputtering indium tin alloy target, comprising the steps of:

[0022] 1) Set the indium-tin alloy twin target and the substrate to be coated in a vacuum chamber with a working pressure of 0.3-0.6Pa;

[0023] 2) Connect the indium tin alloy twin target to the intermediate frequency power supply;

[0024] 3) Introduce the preset reaction gas oxygen and working gas argon into the vacuum chamber to form a plasma region between the indium tin alloy target and the substrate to be coated, so that the indium tin particles are sputtered from the indium tin alloy target come out;

[0025] 4) The deposition process is carried out when the substrate temperature is controlled below 120° C. through the cooling system in the substrate clamping device.

[0026] 5) Using an optical probe to detect the specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com