Preparation method of chloramine phos

A technology of chloramidophos and chloral, which is applied in botany equipment and methods, chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, etc., can solve the problem of increasing production costs and not allowing methamidophos , highly toxic and other issues, to achieve the effects of reduced production costs, increased content, and reduced amounts of impurities and waste disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

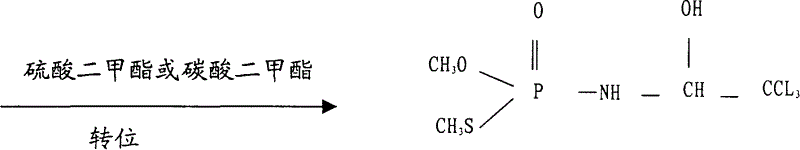

Method used

Image

Examples

example 1

[0026] step one

[0027] Weight ratio: spermine A: chloral = 1: 1.13

[0028] Put 100g of 95% spermine A and 50ml of toluene into a 500ml reaction bottle at one time, start stirring, control the temperature below 30°C and not lower than 5°C, start to slowly add 97% trichloroacetaldehyde dropwise, and add trichloroacetaldehyde dropwise Acetaldehyde 113g, drop in about 1 hour, after dropping, start to keep warm at 29°C and analyze with liquid chromatography until the spermine content in the reaction solution is ≤0.5%, the reaction is the end point, and keep warm for about 5 hours , settled and crystallized at 5°C, a large amount of white solids were produced, filtered and dried, the obtained solid was intermediate C, the weight of the obtained solid was 116g, the melting point was 68°C, and the content was ≥98%. The mother liquor is used as a toluene solvent substitute for the next synthesis reaction, and the C intermediate produced by using the mother liquor has a yield of 187...

example 2

[0033] step one

[0034] Weight ratio: 98% spermine: Chloral = 1:3

[0035] Put 300g of 98% chloral into a 500ml reaction bottle at one time, start stirring, control the temperature below 30°C, not lower than 5°C, start to slowly add 95% spermine dropwise, a total of 100g, after dripping, at 40°C Heat preservation reaction for 3 hours, then raise the temperature to 60°C, continue heat preservation reaction for 2 hours, which is the end point of the reaction, then evaporate excess chloral under high vacuum, cool down to normal temperature, add 100g of n-hexane, stir evenly, measure Among them, the C intermediate content is about 60%.

[0036] step two

[0037] Weight ratio: C: dimethyl carbonate = 1: 0.2

[0038] Put 20g of dimethyl carbonate and 100g of petroleum ether into a 500ml reaction bottle at one time, control the temperature at 40-50°C, and slowly add the C-n-hexane solution generated in the above step 1 dropwise. As the end point of the reaction, crystallize at a...

example 3

[0040] step one

[0041] Weight ratio: spermine: chloral = 1: 2.5

[0042] Put 250g of 98% chloral into a 500ml reaction bottle at one time, start stirring, control the temperature at about 38°C, slowly add 98% spermine dropwise, a total of 100g, after dropping, continue to stir and react at about 15°C for 32 hours, A large amount of solids precipitated, and then the temperature was lowered by 5°C, crystallized, filtered, and dried to obtain intermediate C, with a solid weight of 189 g and a content of 98%. The filtered mother liquor can be recycled.

[0043] Step 2: Same as Step 2 in Example 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com