Pulley rolling equipment

A technology of rolling equipment and pulleys, which is applied in the field of pulley rolling equipment, can solve problems such as insufficient rigidity, and achieve the effects of reasonable structure, durable rope grooves, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

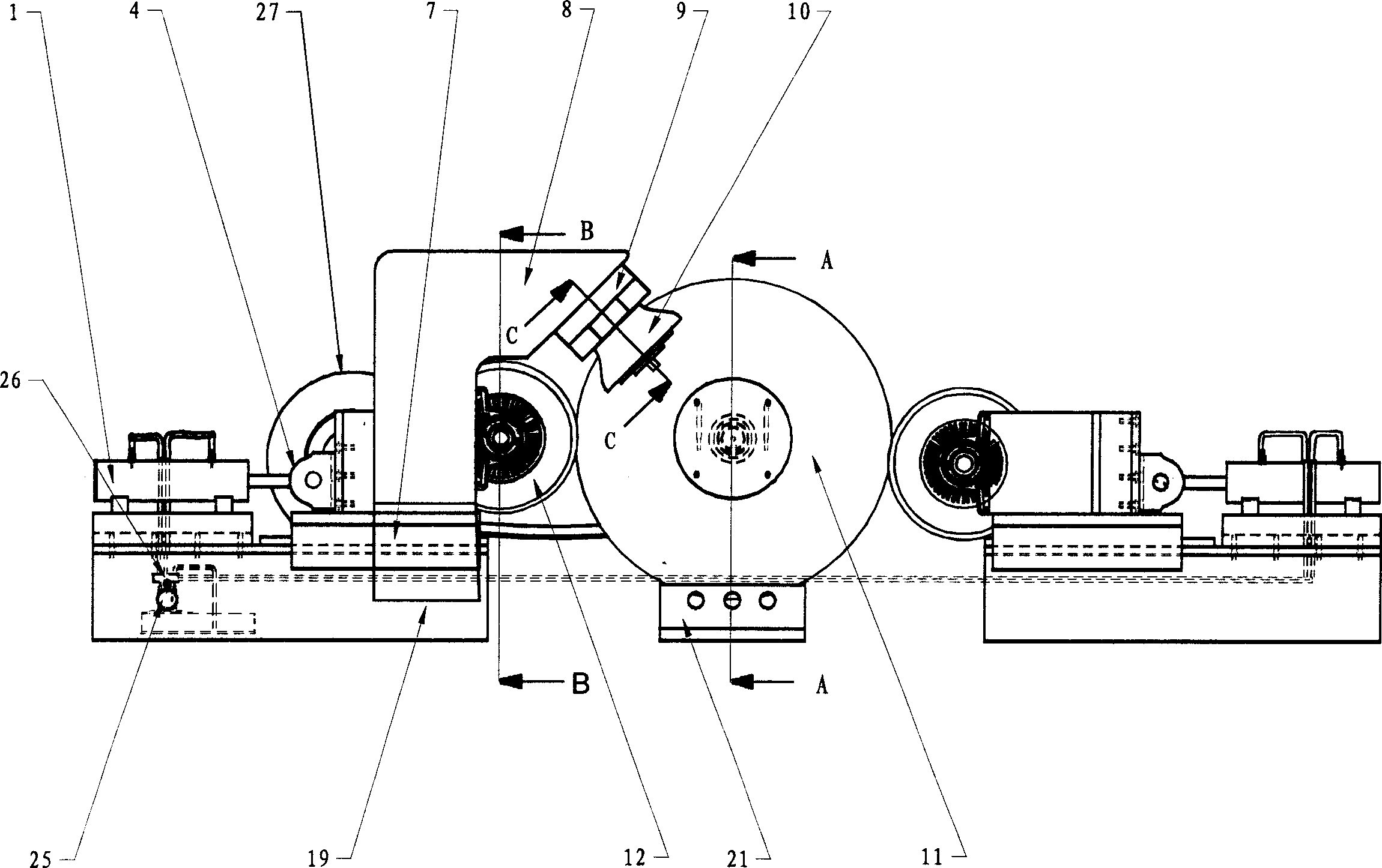

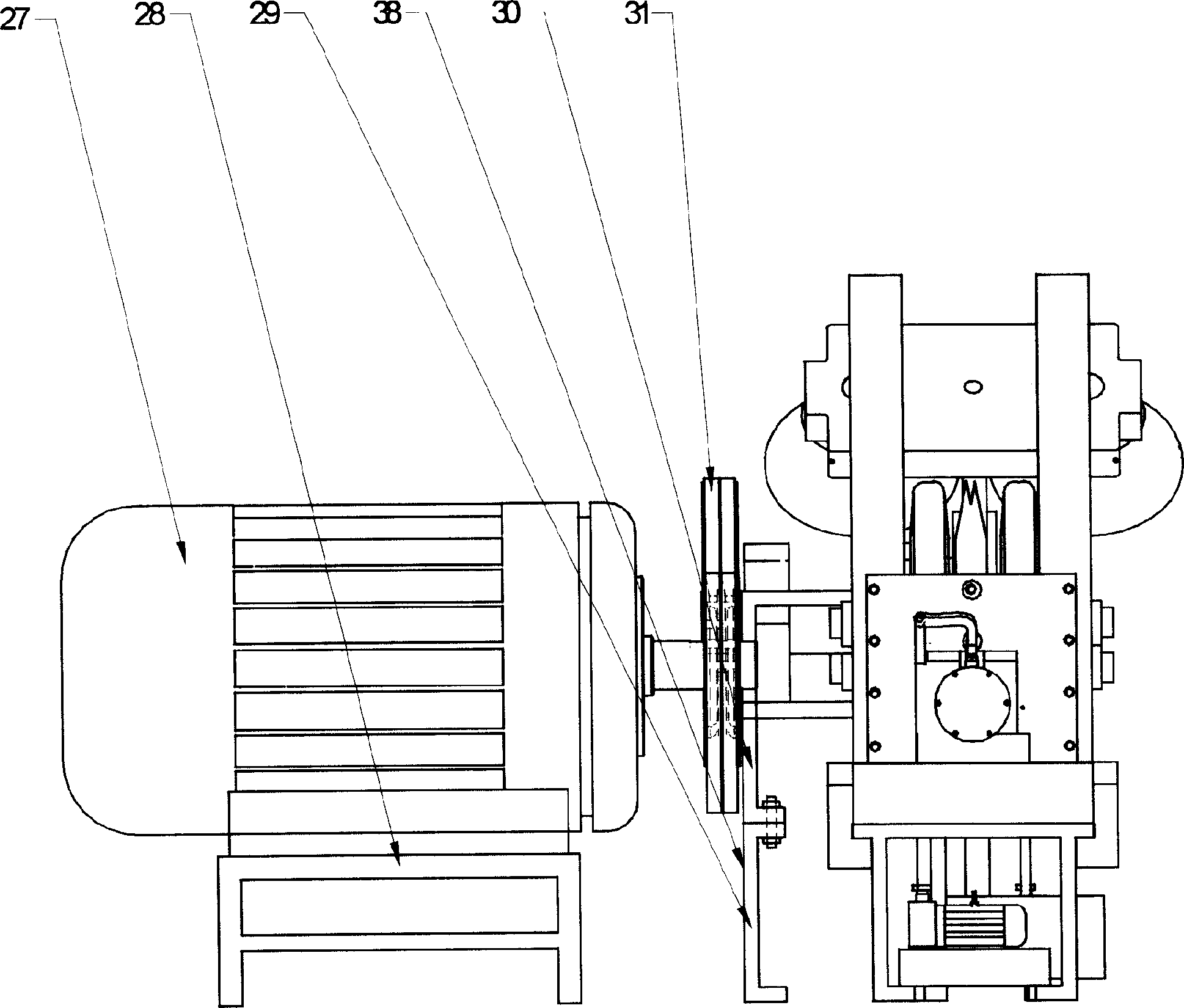

[0019] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 Shown, pulley rolling equipment, it is made up of main frame 19 and main shaft frame 38, motor 27, workpiece supporting mechanism, wheel groove rolling and forming mechanism, wheel rim rolling and forming mechanism 12, hydraulic mechanism 1, heating device 37 and temperature control device;

[0020] like figure 2 , image 3 As shown, the main frame 19 and the main shaft frame 38 are fixedly installed on the same horizontal plane, the main shaft frame 38 includes the lower frame 29 and the upper frame 30, the main shaft 33 and the workpiece supporting mechanism are all installed on the upper frame 30, wherein the main shaft The main bearing 34 of 33 is fixedly installed on the connecting plate 39, and the main shaft 33 is installed in the main bearing housing 40 and the main bearing cover 32; It is fixedly installed on one side of the shaft shoulder of the main shaft 33, and the workpiece 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com