Marmen oil field pumping pipe blocking device

A technology of memory alloy and oil suction pipe, which is applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/pipe fittings, etc., which can solve the problems of corrosion and perforation of oil field oil suction pipes, failure to pump oil, small adhesion and friction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

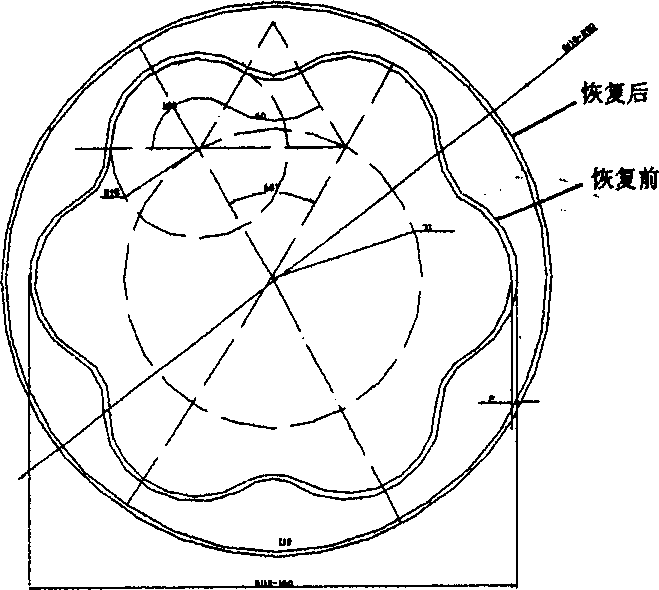

Embodiment 1

[0008] 1. The type of memory alloy used is copper-aluminum-beryllium X series, and the weight percent of the ingredients is: aluminum-9-13%, beryllium-0.1-1.0%, X is chromium-0.02-0.5%, and the rest is copper.

[0009] 2. Using intermediate frequency induction melting, centrifugal casting into a tube blank of 130MM, 6-8MM thick, and 1-6 meters long.

[0010] 3. The tube blank is subjected to homogenization heat treatment, that is, 860°C / 8 hours, air-cooled; then it is heat-treated, that is, 750-860°C / 2 hours, and ice-water cooling; after treatment, it is subjected to 80-500°C / 1 hour aging treatment.

[0011] 4. The processed tube blank is machined into a memory-shaped tube of 126MM, 1-3MM thick, and 1-6 meters long;

[0012] 5. Immerse the memory shaping tube into a liquid nitrogen alcohol solution at about -120°C, or bury it in dry ice for 30 minutes, and press it into a 4-12 petal-shaped plum blossom tube in a mold with a 600-ton press;

[0013] 6. Use the special feeder ...

Embodiment 2

[0015] 1. The kind of memory alloy adopted is copper-zinc-aluminum series, and the weight percent of composition is: zinc 20~32%, aluminum-3.5~6%, the rest is copper.

[0016] 2. Vacuum induction melting is used to cast into a 120MM ingot with a length of 3 meters; the ingot is pierced into a tube blank of 130MM with a thickness of 6 to 8MM and a length of 1 to 6 meters at a temperature of 650-850 ° C. .

[0017] 3-6. Same as 3-6 of Example 1.

Embodiment 3

[0019] 1. The kind of memory alloy used is copper-aluminum-nickel series, and the weight percent of composition is: nickel 20~32%, aluminum-3.5~6%, and the rest is copper.

[0020] 2. Vacuum induction melting is used to cast into a 120MM ingot with a length of 3 meters; the ingot is pierced into a tube blank of 130MM with a thickness of 6 to 8MM and a length of 1 to 6 meters at a temperature of 650-850 ° C. .

[0021] 3-6. Same as 3-6 of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com