Machining mould and method for stainless nide silk bobbin

A technology for processing molds and stainless steel pipes, applied in the direction of wire reeling, etc., can solve the problems of difficult forming of stainless steel materials, easy surface oxidation, poor mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

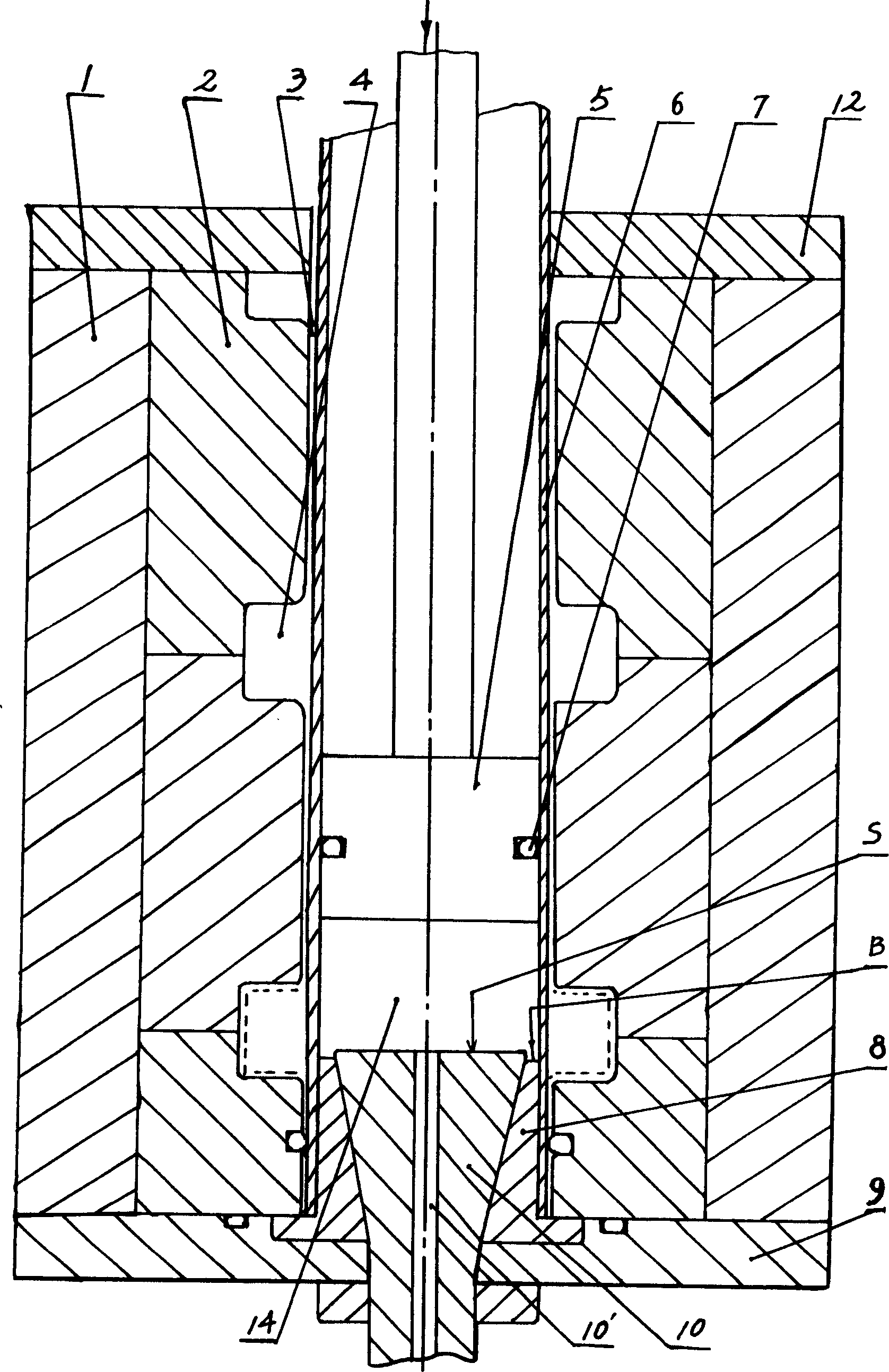

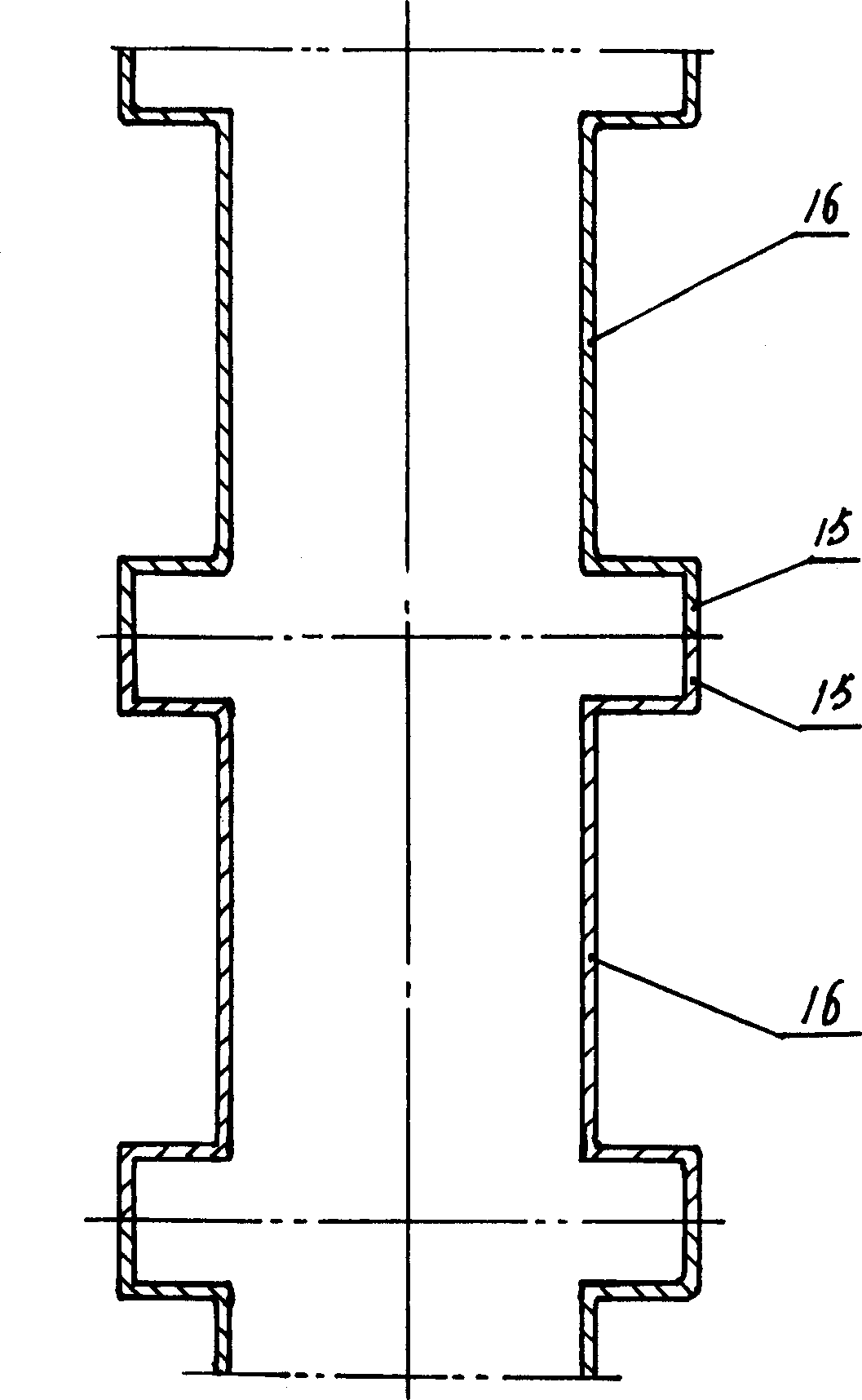

[0009] The invention discloses a processing mold and a processing method for a stainless steel nest wire bobbin. Its described processing mold such as figure 1 As shown, a mold cavity is formed in the mold, and a mold core is installed in the mold cavity. It is characterized in that the mold can be a section (integral mold) or a combined mold 2 divided into several sections, and the mold cavity is segmented. The cylindrical cavity 3 (diameter is equivalent to the size of the nest wire bobbin) and the expanded end cover cavity 4 (the diameter is equivalent to the size of the two ends of the nest wire bobbin) are composed of sections between each other, and the movable mold core 5 is installed in the cavity. , the movable mold core withdraws a section after making a section of molding, inserts the stainless steel tube 6 into the mold cavity between the mold 2 and the mold core 5, installs a seal 7 between the mold core and the stainless steel tube 6, and inserts a seal 7 at one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com