Pouring weight loaded buffering mechanism

A buffer mechanism and heavy block technology, applied in the field of buffer mechanism, can solve problems such as failure to achieve unloading purpose, and achieve the effect of reliable operation, wide application range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

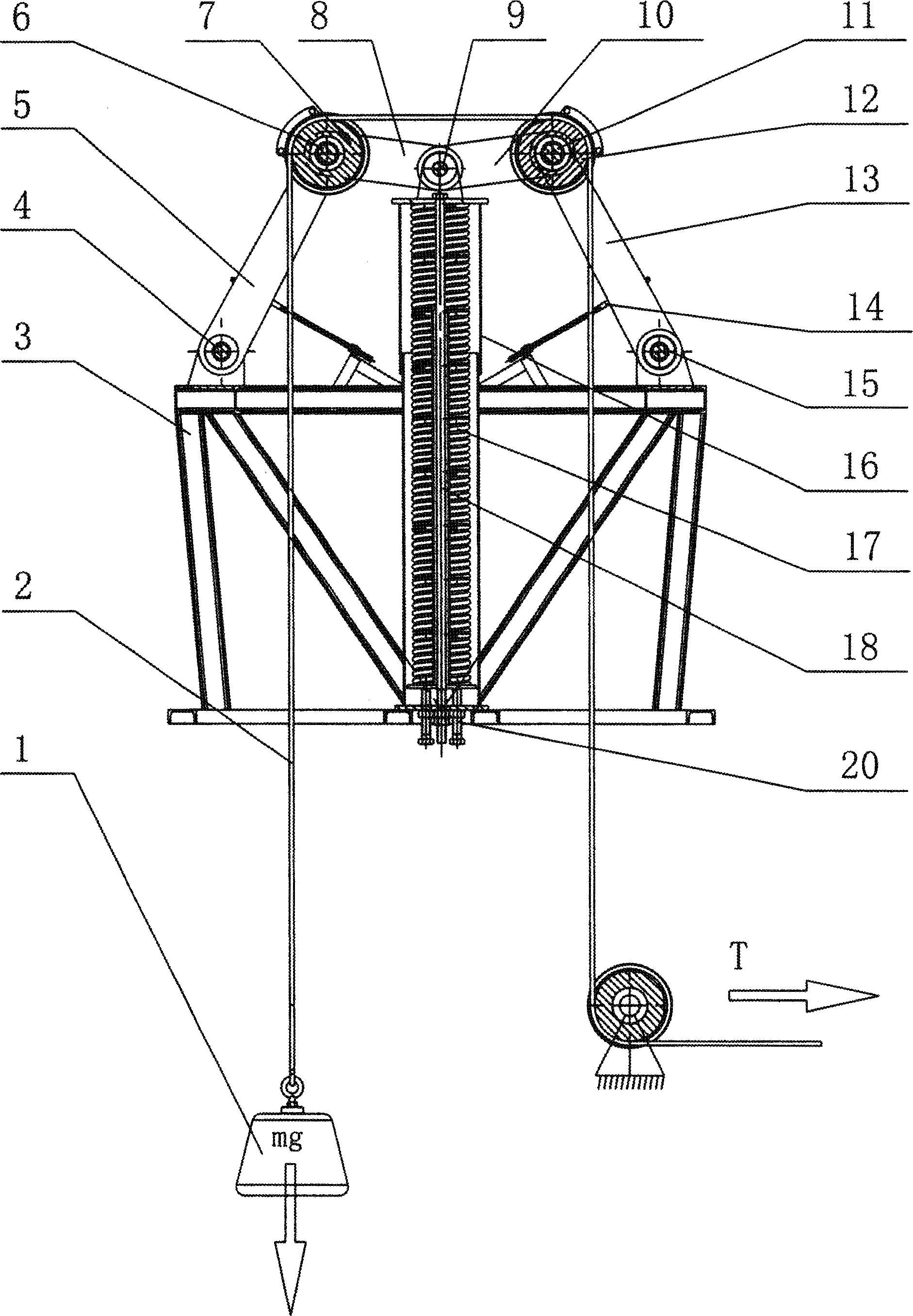

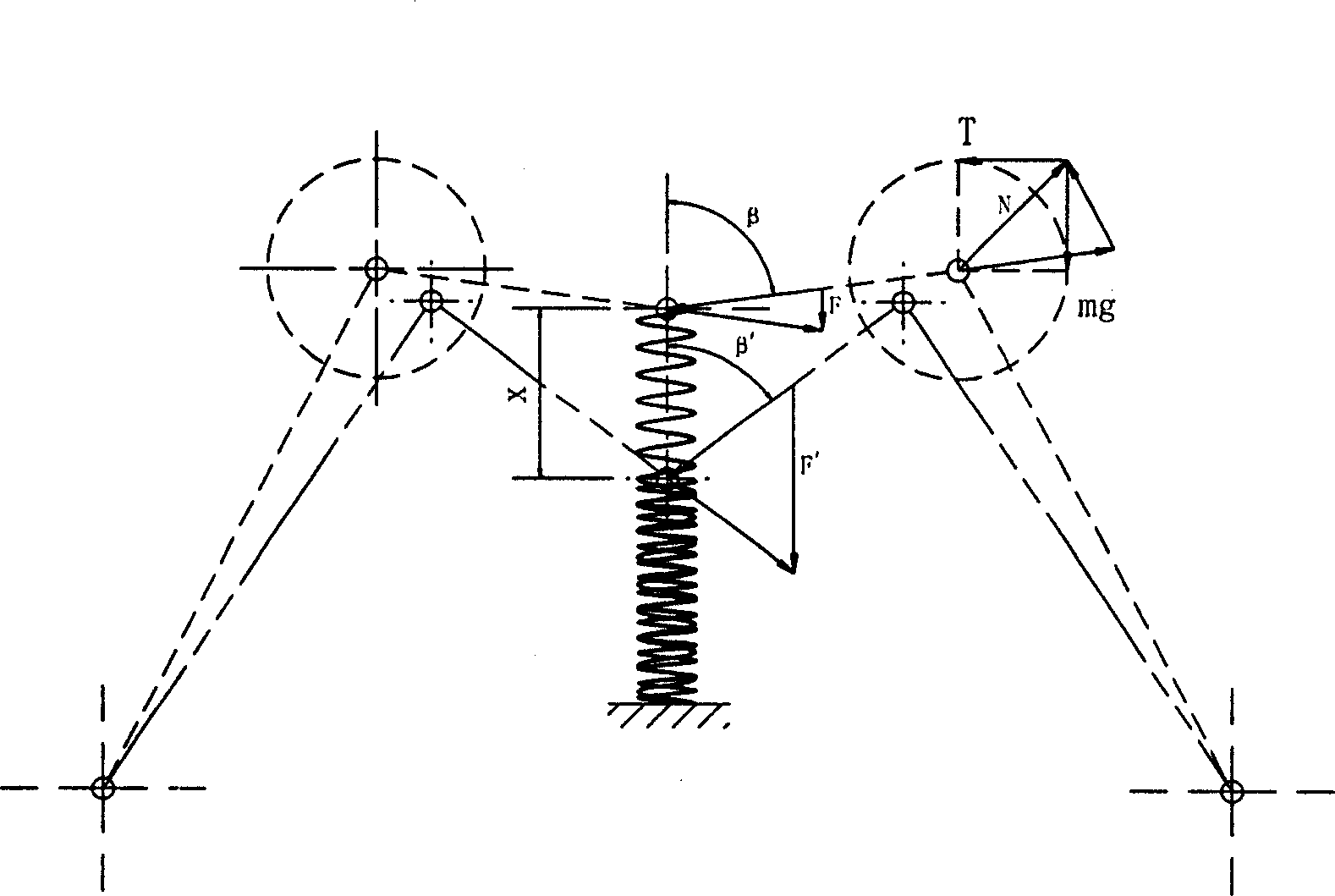

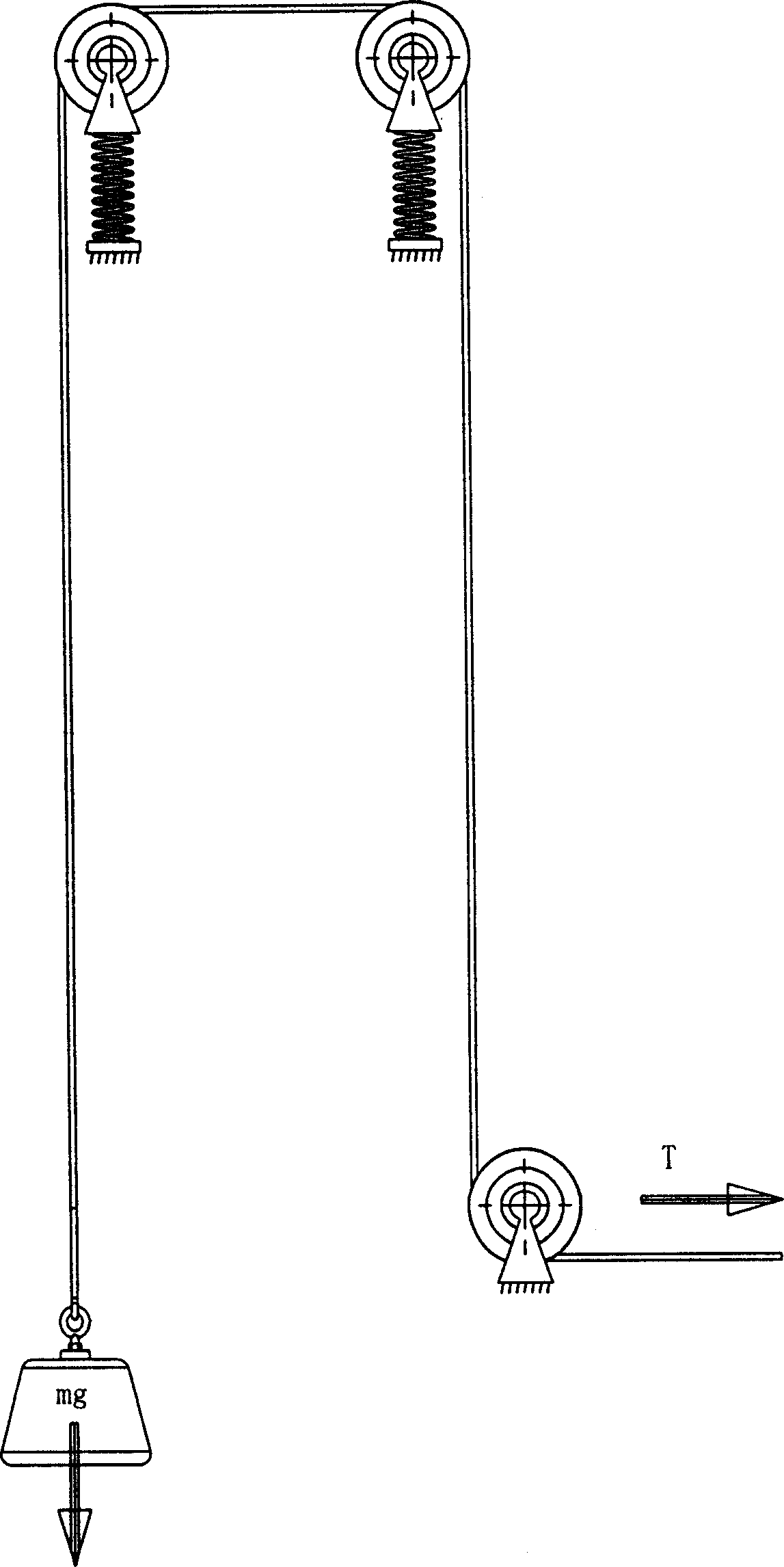

[0018] see figure 1 One end of the left connecting rod 5 and the right connecting rod 13 are respectively arranged symmetrically with the frame 3 to be hinged, and the other ends of the left connecting rod 5 and the right connecting rod 13 are connected with the upper left connecting rod 8 and the upper right through the left shaft 6 and the right shaft 11 respectively. One end of the rod 10 is hinged, the left shaft 6 and the right shaft 11 are respectively provided with a left pulley 7 and a right pulley 12, the other ends of the left upper link 8 and the right upper link 10 are hinged with the spring seat 16 through the central shaft 9, and the combined spring 17 is installed Between the frame 3 and the spring seat 16, one end of the long screw 18 is connected to the frame 3, and the other end is connected to the spring seat 16 to adjust the spring pressure; the adjusting bolt 20 is installed at the bottom of the frame 3 to adjust the combined spring 17 , central axis 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com