Vertical disc-shaped cam with small cam arranged internally

A disc cam and small cam technology, which is applied in the direction of cams, toothed elements, belts/chains/gears, etc., can solve the problems of damage to the cam shell and counterweight, failure to meet precision transmission, and unstable operation of the cam, etc. , to achieve the effect of long service life, reduced torque and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is described further in detail:

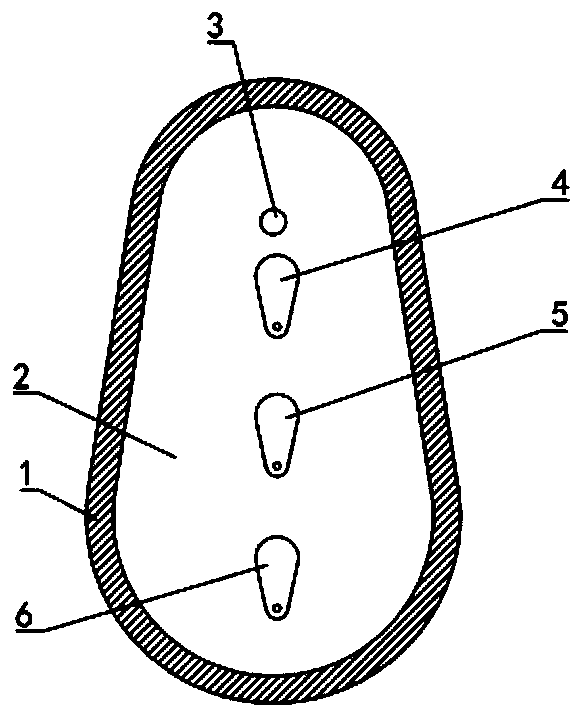

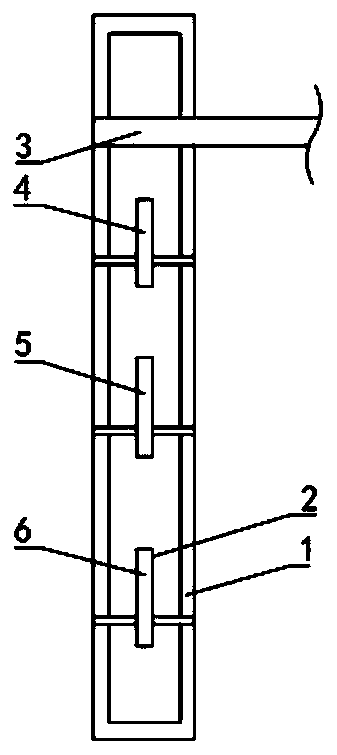

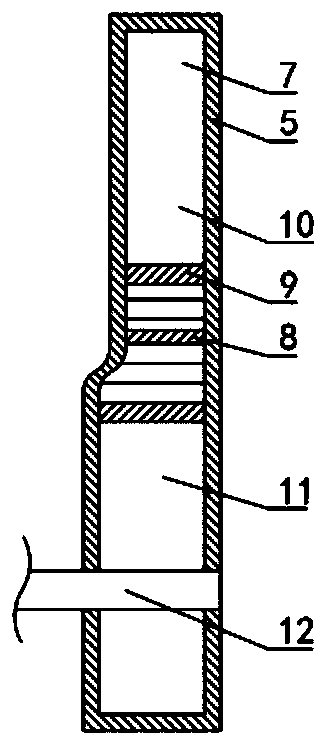

[0027] A vertical disc cam with a built-in small cam, including a vertically arranged cam body 1, the cam body 1 is installed on the transmission shaft 3 and rotates synchronously with the transmission shaft 3, the cam body 1 is provided with a cam cavity 2, and the cam cavity 2. The first adjustment cam 4, the second adjustment cam 5 and the third adjustment cam 6 are installed in rotation, and the first adjustment cam 4, the second adjustment cam 5 and the third adjustment cam 6 are all arranged on the long axis of the cam body 1 , and arranged at intervals along the direction close to the transmission shaft 3, the first adjusting cam 4, the second adjusting cam 5 and the third adjusting cam 6 are all connected with torsion springs, so that the first adjusting cam 4, the second adjusting cam 5 and the second adjusting cam The salie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com