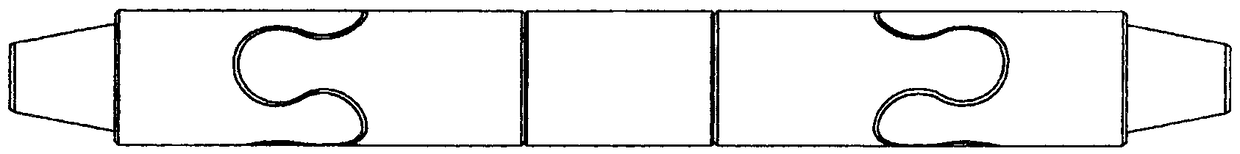

Universal shaft

A technology of cardan shaft and petal, applied in the field of cardan shaft, can solve the problems of small contact area, short service life, large contact stress of meshing pair, etc., and achieve the effect of large contact area and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

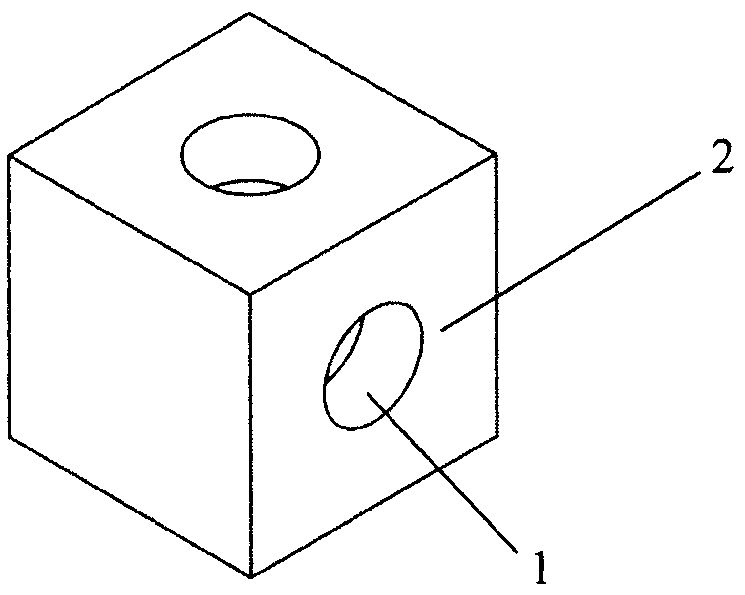

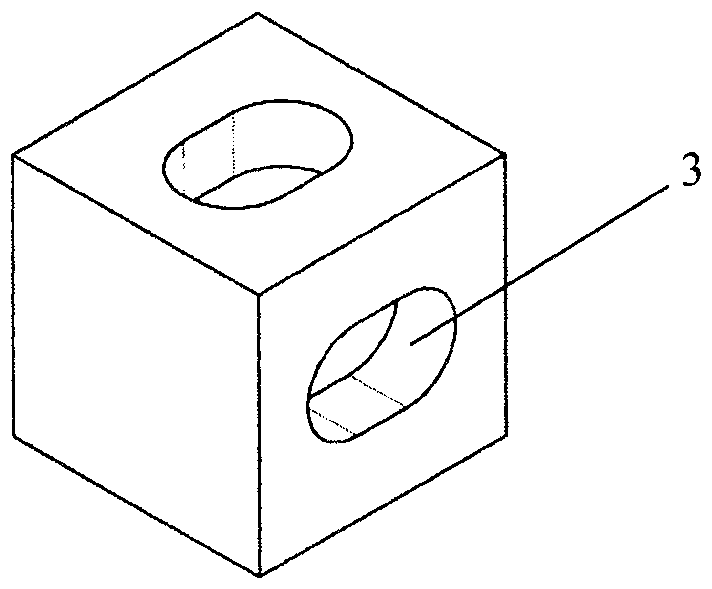

[0015] Such as figure 2 As shown, the shape of the slider (8) is a cube, and except for the two opposite faces, there is a hole (1) for assembling a positioning pin on each of the other four faces, and the axis of the hole (1) is located at the center of the square. And perpendicular to the plane (2) where the square lies. Such as Figure 4 As shown, there is a gap on the petal body (7), the two sides of the gap are two parallel planes (4), the size of the gap is just equal to or slightly larger than the side length of the slider (8), on both sides of the gap Each has a hole (5) for assembling a positioning pin, these two holes (5) are coaxial, and the axes of the holes (5) are perpendicular to the two parallel planes (4) on both sides of the gap. Such as Figure 6 As shown, two petal bodies (7) in the middle are contained on the intermediate shaft (10), guarantee that these two petal bodies (7) are on the same axis (or these three parts are made into one). Put the slider...

Embodiment 2

[0017] The structure is similar to the first embodiment, only the positioning pin (9) and the slider (8) are fixed, the positioning hole (5) on the petal body (7) is changed into a short groove (6), the groove (6) The direction is consistent with the axis of the petal body (7). Its effect is: if the petal body (7) of upper and lower end has slight axial displacement, positioning pin (9) can slide in groove (6) without force, still can play positioning effect.

Embodiment 3

[0019] The structure is similar to that of Embodiment 1, except that the positioning pin (9) and the petal body (7) are fixed, and the positioning hole (1) on the slider (8) is changed into a short groove (3), and the groove (3) The direction is consistent with the axis of the cardan shaft. Its effect is: if the petal body (7) of upper and lower end has slight axial displacement, positioning pin (9) can slide in groove (3) without force, still can play positioning effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com