Method for implanting ions in semiconductor device

An ion implantation, semiconductor technology, applied in semiconductor/solid-state device manufacturing, instruments, table utensils, etc., can solve problems such as differences in electronic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

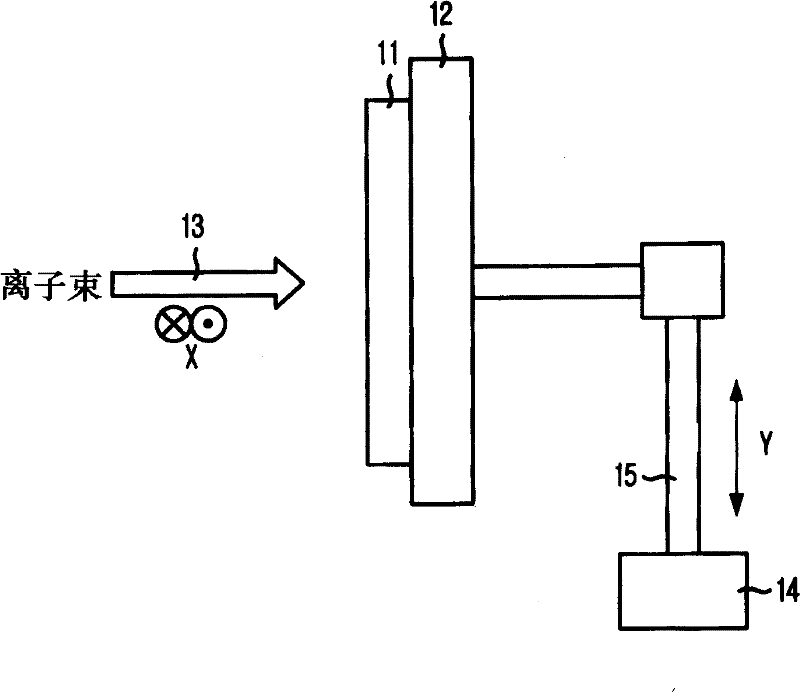

[0031] The ion implantation method in the semiconductor device according to the first embodiment of the present invention will be described in detail with reference to the accompanying drawings.

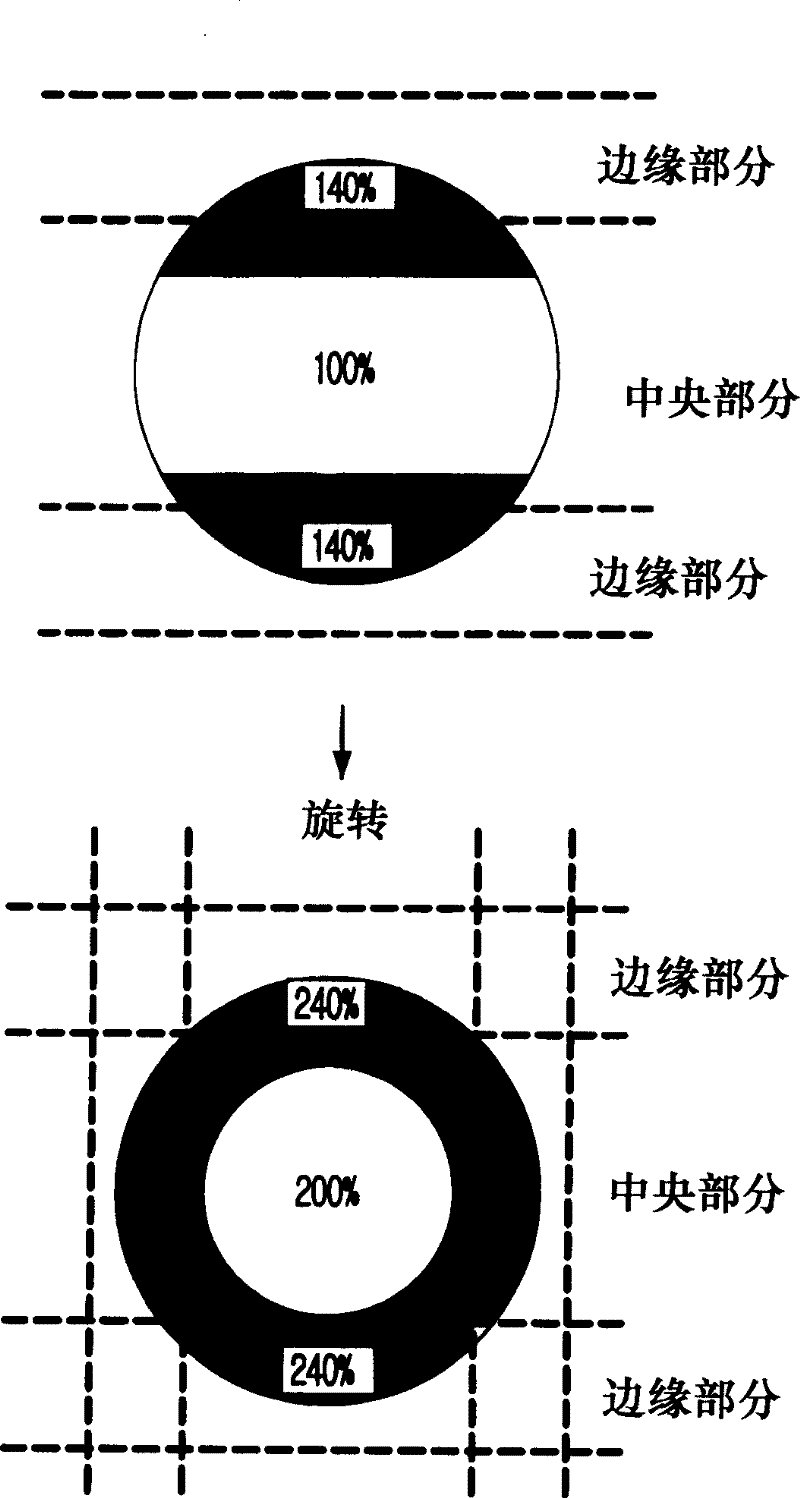

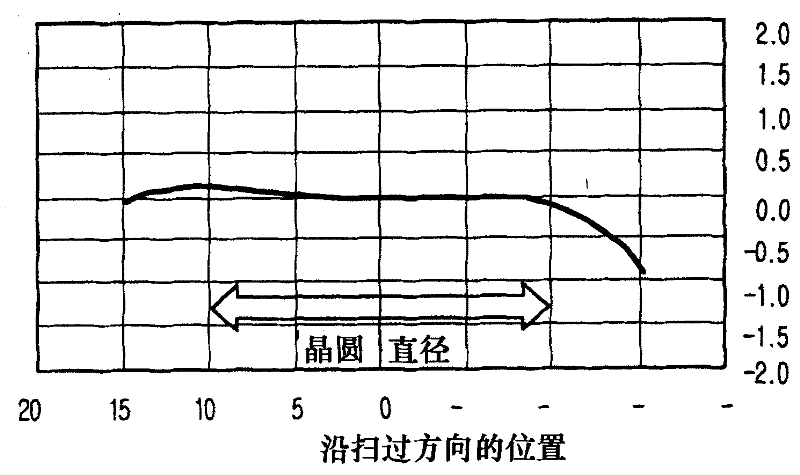

[0032] According to the present invention, the reciprocating scanning speeds in the X and Y directions are set differently according to the position of the substrate used in the non-uniform ion implantation method.

[0033] The present invention is invented based on the technical principle to identify the difference in the critical dimension (CD) of the gate in a substrate, and not cause the difference in the semiconductor device parameters in the substrate by performing non-uniform ion implantation.

[0034] For example, if the critical dimension of the gate in the central portion of the semiconductor is larger than in the edge portion of the substrate, the central portion of the semiconductor device will have a higher threshold voltage (V T ). Therefore, at the threshold voltage (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com