Turbine rotor repair method

A technology of turbines and rotors, applied in turbines, mechanical equipment, engine components, etc., can solve problems such as reheat cracks, coarse grains, and deep welding depth and shape in the welded part.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

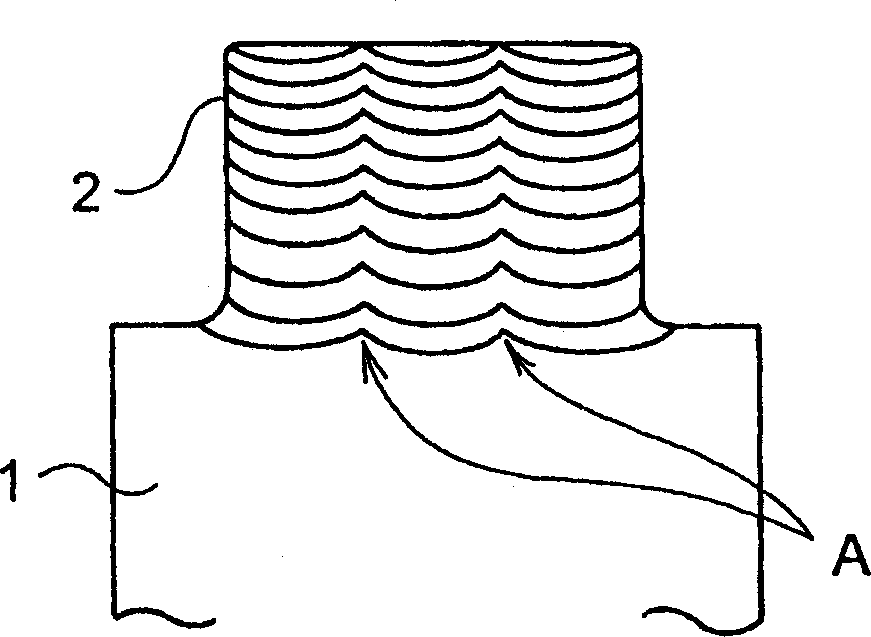

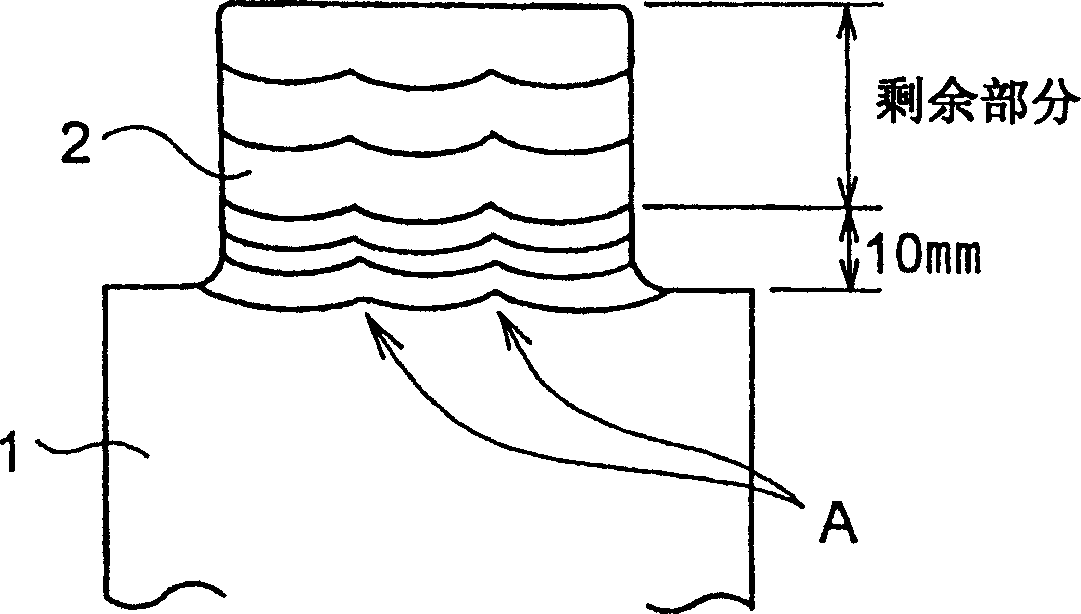

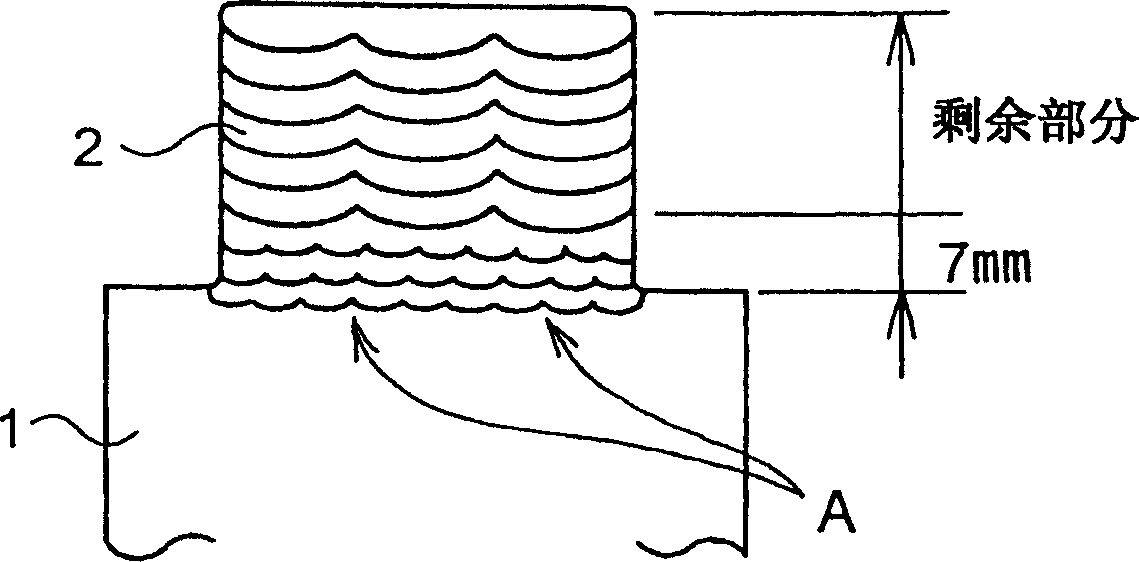

[0029] Embodiments of the present invention will be described with reference to the drawings. In the following figures, the same reference numerals are assigned to the parts that play the same role. figure 1 It is a longitudinal cross-sectional view schematically showing a repair state of the rotor by the repair method according to the first embodiment of the present invention. In order to completely fine-grain the above-mentioned welding heat-affected zone, it is important to perform overlay welding with a shallow weld bead. In order to perform welding with a high deposition rate, submerged arc welding is used in this embodiment.

[0030] Generally, it is difficult to perform shallow welding with submerged arc welding, but by using a conductive flux, it is possible to perform welding with a wide arc and a wide width and a shallow welding depth. As the conductive flux, for example, flux PFH-203 manufactured by Kobe Steel Works, Ltd. can be used.

[0031] Furthermore, weldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com