High pressure sealing ring current type crude oil wax deposition simulating device

A high-pressure sealing and simulation device technology, applied in the field of pipeline systems, can solve the problems of cumbersome wax deposition process and affecting the accuracy of loop simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

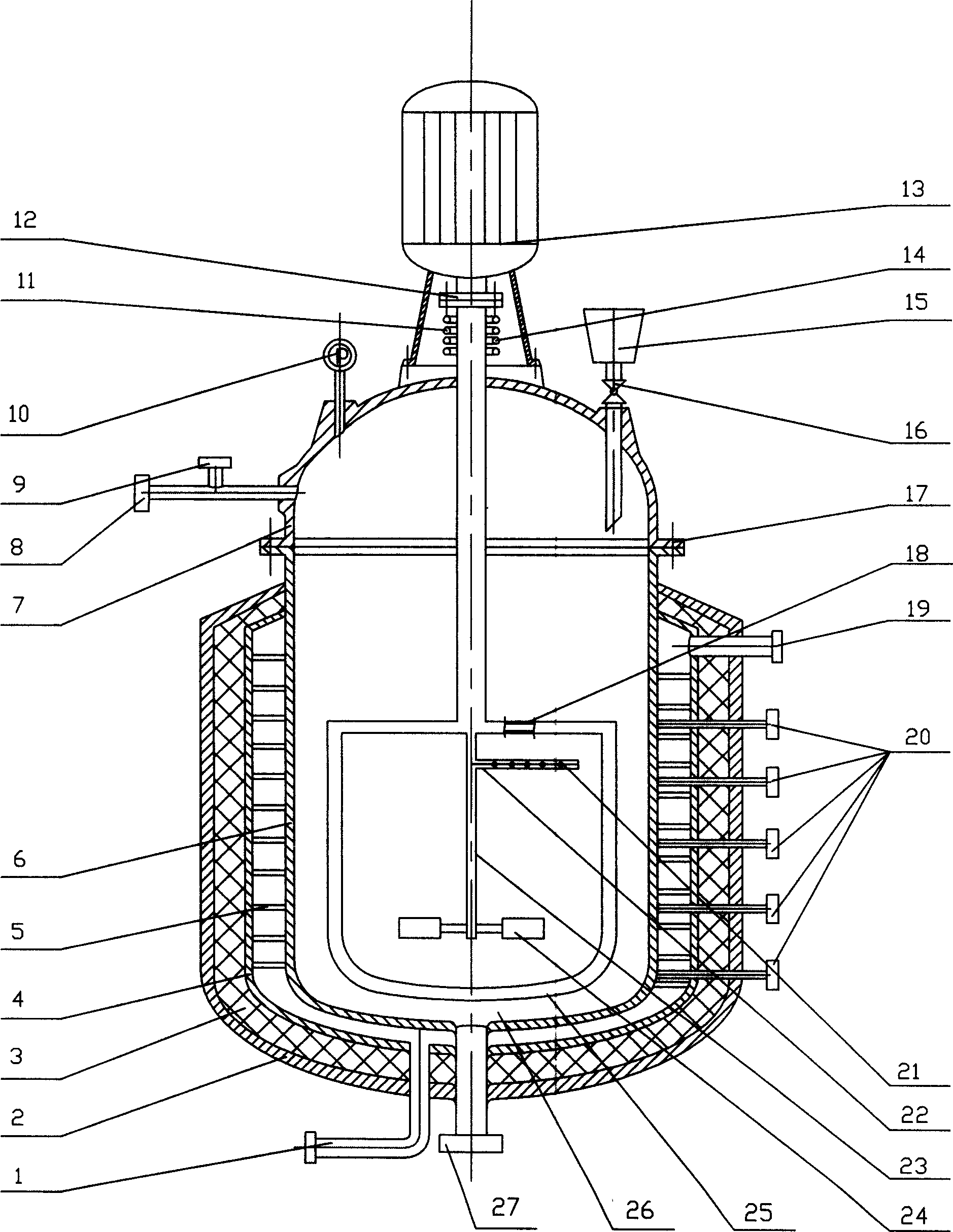

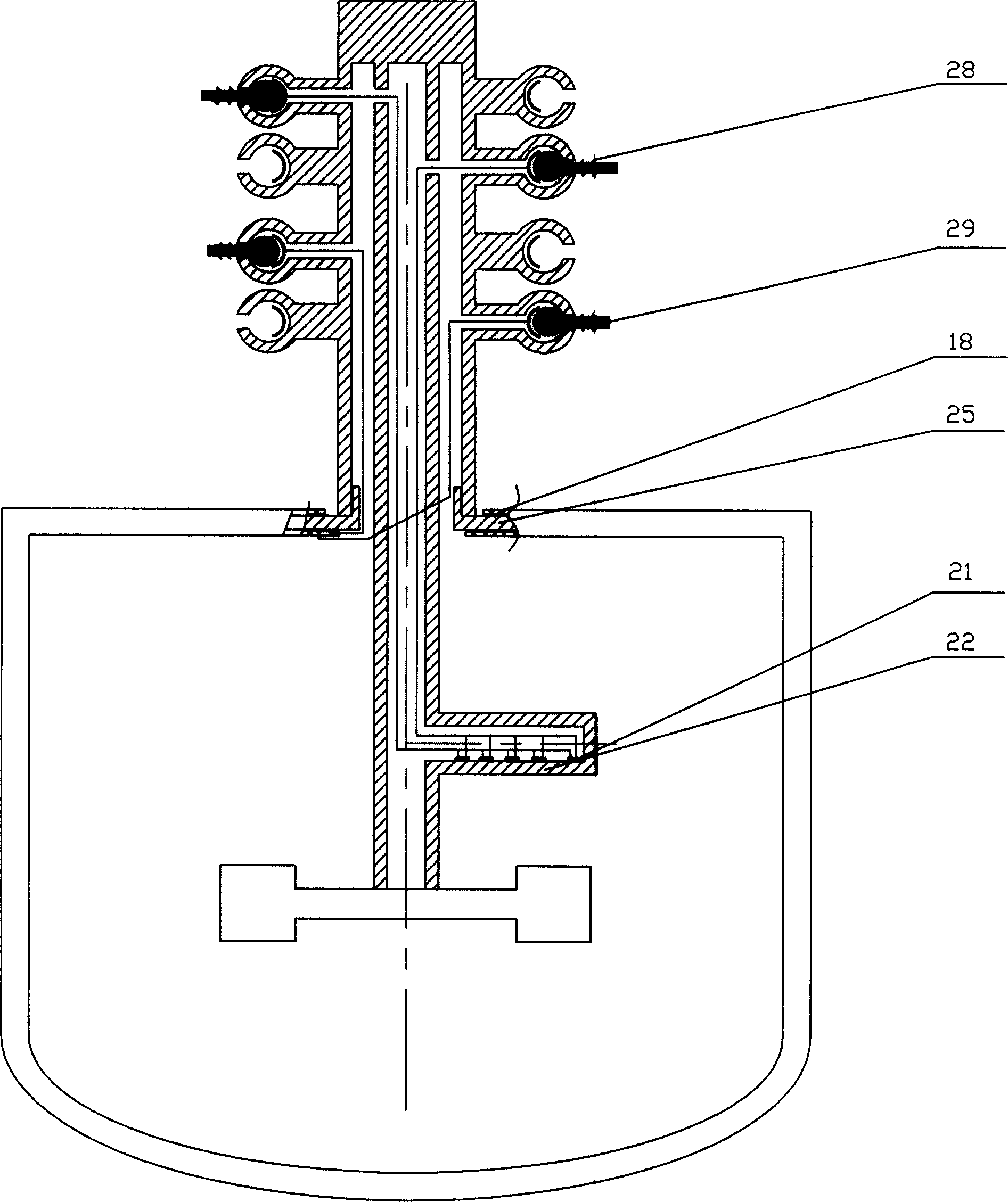

[0006] Embodiment: take kettle 26 internal diameter 400mm, high 200mm as example, its specific structure is as figure 1 , figure 2 shown. The main equipment and dimensions are: the inner tank is 150mm high and 10mm thick, the kettle cover 7 is 50mm high, the jacket 4 is 50mm wide, the spiral deflector 5 is coiled 5 times in the jacket 4, the insulation layer 3 is 50mm wide, and the shell 2 is thick 5mm, the insulation layer 3 is filled with asbestos. The motor 13 is 1KW, the shaft of the agitator 23 is made of Φ20mm×2 steel pipe with a length of 200mm, the outer pipe of the vertical casing outside the shaft is made of a Φ30×5mm steel pipe with a length of 100mm, and the anchor type circulation generator 25 is 300mm wide and 120mm high. The Φ10×2mm steel pipe is bent into an anchor shape and welded with the vertical casing. The electric heating cable (line) 18 is wound on the anchor type circulation generator 25 and then passed through the vertical casing and welded on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com