Thermal driven mini-type actuator

A micro-actuator and heat-driven technology, which is applied in the direction of microstructure technology, microstructure devices, and manufacturing microstructure devices, can solve the problems of killing cells and limiting cell operation, and achieves a structure that is not easy to break and has a low Young's modulus. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

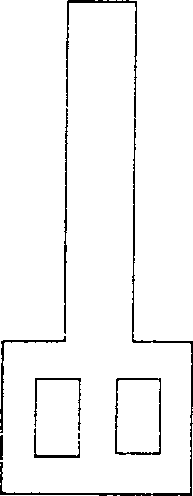

[0031] Such as figure 1 As shown, the thermally driven micro-actuator of the present invention has the effect of electrothermal braking, and can be designed and processed to have multiple cantilever beam structures (fingers) to complete micro-operations such as cell capture and clamping. Each cantilever beam is installed on a silicon substrate and has a three-layer structure. Titanium and platinum are used as resistance heating materials, and titanium and platinum are placed between parylene C (a polymer material); that is, titanium and platinum are clamped by parylene C. The three-story structure constitutes a cantilever beam. This embodiment is 4 cantilevers (or fingers), see Figure 4 .

[0032] Among them: the resistance heating material can be a few-shaped structure or any shape (see figure 2 , 3 ).

[0033] The maximum working temperature of the thermally driven micro-actuator cantilever beam of the present invention is 70°C, and the voltage when it is fully bent i...

Embodiment 2

[0047] This embodiment is 2 cantilevers (or fingers, see Figure 8 ). Its processing technology differs from embodiment 1 in that:

[0048] Use 6100 Å light conditions to grow silicon oxide on the silicon chip as the substrate 1; apply a photoresist with a thickness of 1.0 μm on the desired part of the silicon substrate; the thickness of parylene C as the first layer 3 is 0.25; the resistance material titanium The thickness is 550 Å, and the platinum thickness is 1950 Å.

Embodiment 3

[0050] The present embodiment is 6 cantilever beams, and its processing technology differs from embodiment 1 in that:

[0051] On the silicon chip, use 5900 Å light conditions to grow silicon oxide as the substrate 1; apply a photoresist with a thickness of 1.8 μm on the required part of the silicon substrate; the thickness of parylene C as the first layer 3 is 0.35; the resistance material titanium The thickness is 450 Å, and the platinum thickness is 2050 Å.

[0052] The two usage states of the six-finger gripper in this embodiment are as follows: Figure 7-1 , 7-2shown. The index of the present invention should be determined according to the actual application.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| power consumption | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com